Chassis Information --- Section 10

Cayman 2005

321

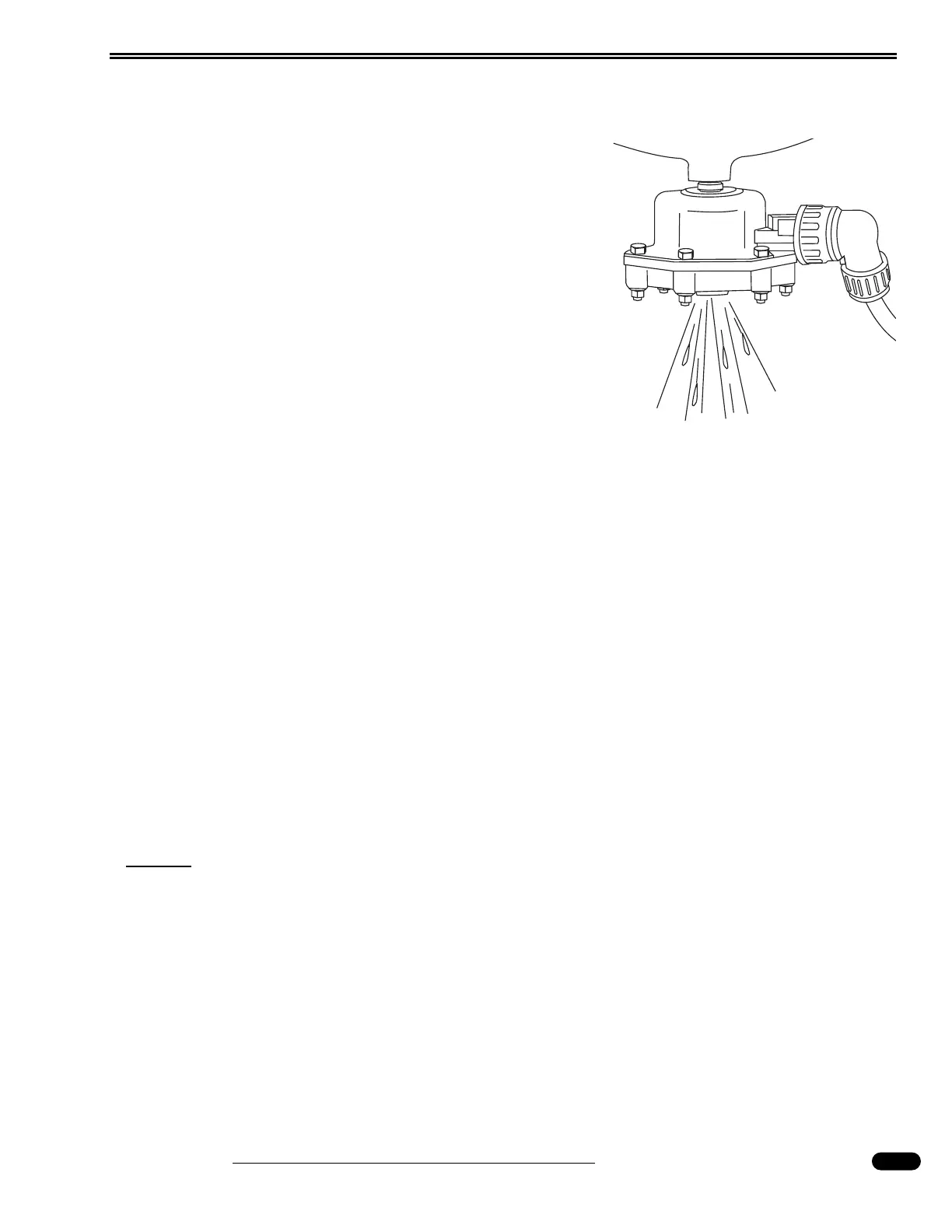

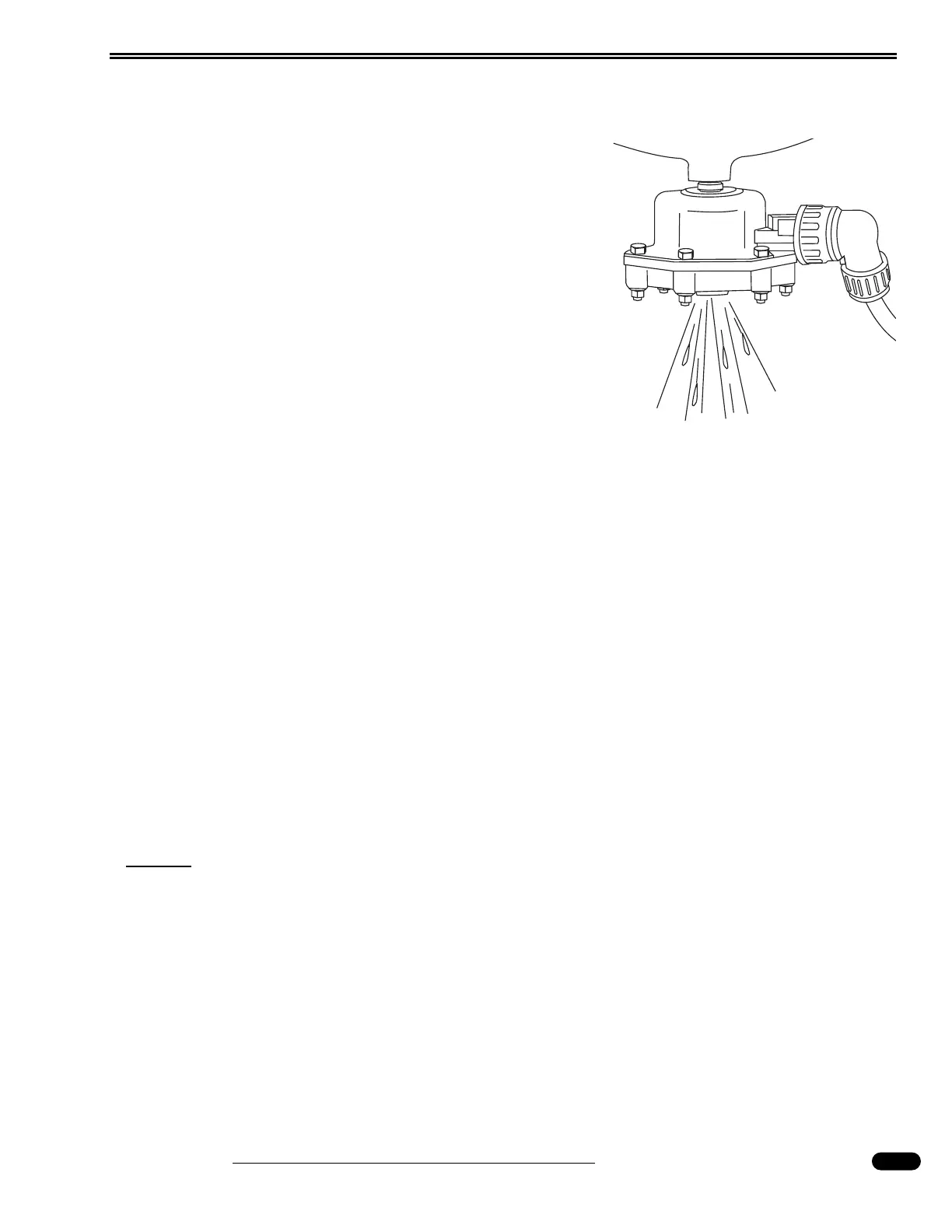

AIR SUPPLY SYSTEM

The air compressing system on the motorhome consists of

an air compressor, air governor, and air tank. The compressed

air system operates several items, some of which include: suspen-

sion, an air gauge (depending on options) and stepwell cover. A

gear driven air compressor mounted on the engine charges the

system. As engine speed increases, compressed air output

increases. When air is compressed, heat is generated. Heat dissi-

pates as the air is discharged from the compressor. Moisture

condenses in the compressed air as it cools. Moisture laden air

is released through the automatic drain on the bottom of the air

tank. The air tank is divided in two halves: a wet side and a dry

side. The compressed air enters the wet side before entering the

dry side. The tank is equipped with a pop valve for over-pres-

sure protection, a manual drain valve and automatic drain valve.

The manual drain is located on the DRY side of the tank. The

pop valve and automatic drain valve are located on the WET

side. The pop valve is designed to release pressure in the tank

when the pressure exceeds 130 psi. With the ignition switched

to ON, the automatic drain valve (standard brake models)

wired to the brake light circuit will activate each time the

brakes are applied. Only a small amount of air/water is

expelled. The momentary release of air/water from the tank is audible.

Pneumatically operated items are divided into two categories: brakes and accessory air. Brakes have

full use of supplied air pressure. Accessory air items, such as a stepwell cover, receive air through a pres-

sure protection valve (PPV). The PPV will not allow compressed air flow until approximately 60 psi. In

case of an air system problem, the pressure protection valve will leave a reserve air charge for braking.

Pressure protection valves are installed for safety.

A low-pressure air switch connected to a warning lamp on the dash console monitors the air system.

The lamp will illuminate when a low-pressure condition exists. Check the operation of the low air lamp

when the air tank is drained.

NOTE:

The air tank should be drained manually every 30 days. Open the manual drain on

the bottom of the tank until all air escapes. Leave valve open an additional five

minutes allowing excess moisture to drain.

Automatic drain on standard brake models.

040380

Loading...

Loading...