MSD Single-Axis System Operation Manual AC-AC Servo Drive

ID no.: CA65642-001 06/2018

moog

41

Electrical installation

4.14.3 Ready made encoder cables

The specications can only be assured on the usage of Moog system cables.

C08335 - 013 - yyy

Encoder cable

Ready made cable

Resolver cable

Encoder cable SSI, EnDat CA58876

Encoder cable Hiperface® CA58877

002

002

Encoder system

Version

Cable length (m)

1) yyy stands for length in meters; standard length: 1 m (3.28 ft), 5 m (16.40 ft), 10 m (32.80 ft), 15 m (49 ft), 20 m (65 ft),

50 m (164 ft). Further length on request

Encoder cable C08335-013-yyy

1)

Order code

CO8335-013-yyy

1)

CA58876-002-yyy

1)

CA58877-002-yyy

1)

Motors with encoder system Resolver

G3, G5, G12.x

(singleturn / multiturn

encoder with SSI/EnDat

interface)

G6, G6.x

(singleturn / multiturn

encoder with

HIPERFACE

®

interface)

Drive-end assignment

(Sub-D connector)

1 = S3

2 = S1

3 = S2

4 = n.c.

5 = PTC+

6 = R1

7 = R2

8 = S4

9 = PTC-

1 = A-

2 = A+

3 = VCC (+5V)

4 = DATA+

5 = DATA-

6 = B-

8 = GND

11 = B+

12 = VCC (Sense)

13 = GND (Sense)

14 = CLK+

15 = CLK-

7, 9, 10 = n.c.

1 = REFCOS

2 = +COS

3 = U

S

7 – 12V

4 = Data + RS485

5 = Data- RS485

6 = REFSIN

7 = Jumper to pin12

8 = GND

11 = +SIN

12 = Jumper to pin7

9, 10, 13, 14, 15 = n.c.

Capable for energy chains Yes

Minimum bending radius 90 mm (3.54 in) 100 mm (3.93 in) 90 mm (3.54 in)

Temperature range

-40 to +85 °C

(-40 to +185 °F)

-35 to +80 °C

(-31 to +176 °F)

-40 to +85 °C

(-40 to +185 °F)

Table 4.15 Technical data, encoder cables

CO8335-013-yyy

1)

CA58876-002-yyy

1)

CA58877-002-yyy

1)

Cable diameter approx. 8.8 mm (0.34 in)

Outer sheath material PUR

Resistance Oil, hydrolysis and microbe resistant (VDE0472)

Approvals

UL style 20233, +80 °C (+176 °F) - 300V,

CSA-C22.2N.210-M90, +75 °C (+167 °F) - 300V FT1

Table 4.15 Technical data, encoder cables

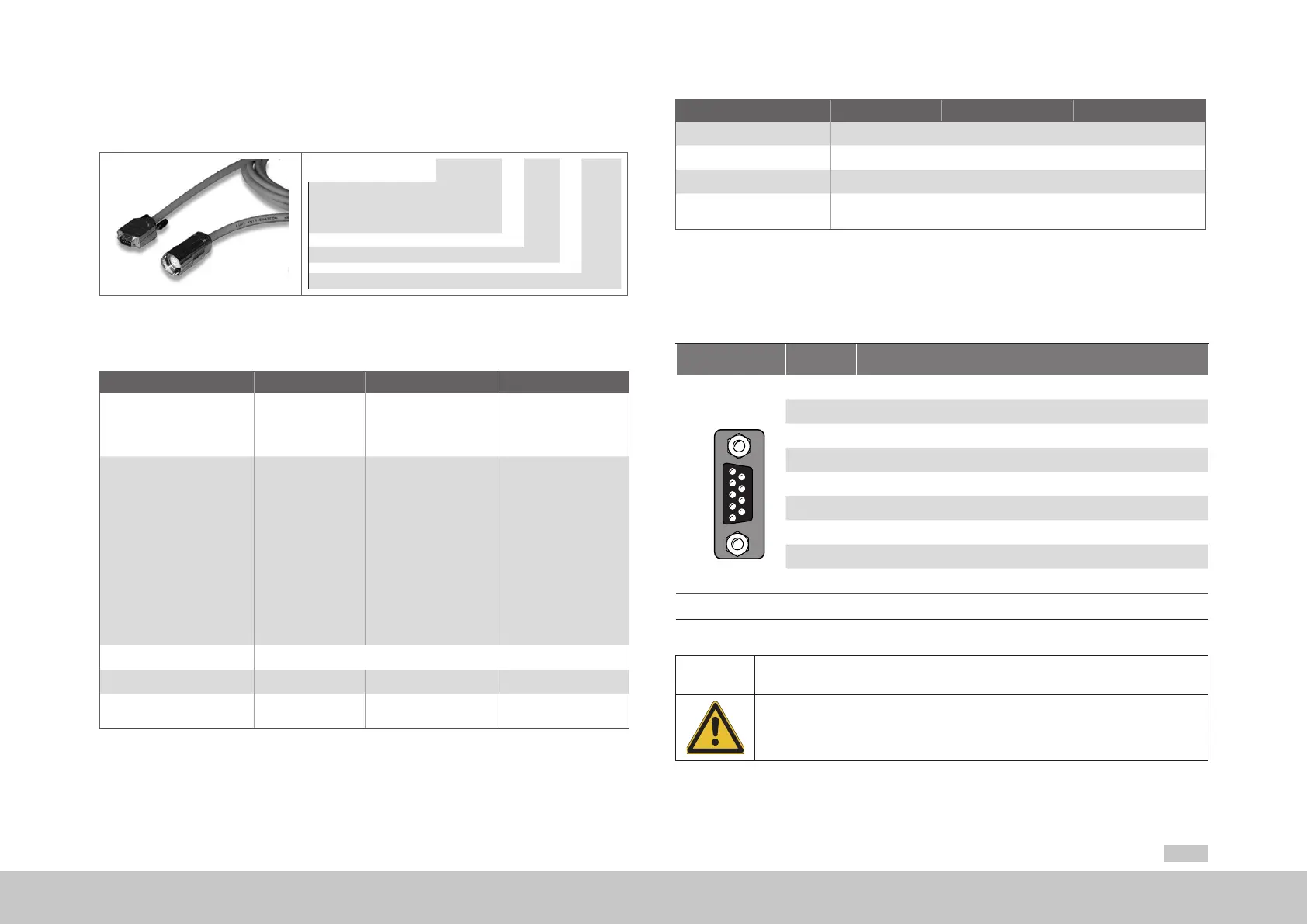

4.14.4 Resolver connection

A resolver is connected to slot X6 (9-pin D-Sub socket).

Fig. X6/pin Function

5 4 3 2 1

9 8 7 6

X6

Resolver

1 Resolver S3 differential input (reference to Pin X6-2)

2 Resolver S1 differential input (reference to Pin X6-1)

3 Resolver S2 differnetial input (reference to Pin X6-8)

4 Supply voltage 5..12V, connected internally to X7/3

5

ϑ+ (PTC, NTC, KTY, Klixon) 1)

6 Ref+ analog excitation

7 Ref- analog excitation (ground reference point to pin6)

8 Resolver S4 differntial input (reference to Pin X6-3)

9

ϑ- (PTC, NTC, KTY, Klixon)

1)

1) It is imperative attention is paid to the warning

Table 4.16 Pin assignment X6

CAUTION

Damage to the device due to incorrect insulation of the motor

winding!

• Carelessness can cause damage to the motor/device

The motor temperature sensor must, in relation to the motor winding, on connection to X5 be

provided with basic insulation, on connection to X6 or X7 with reinforced insulation

as per IEC/EN61800-5-1.

Loading...

Loading...