SECTION5–MAINTENANCESCHEDULEANDSERVICEPROCEDURES

ServiceProcedures(cont.)

ENGINEOILANDFILTER(cont.)

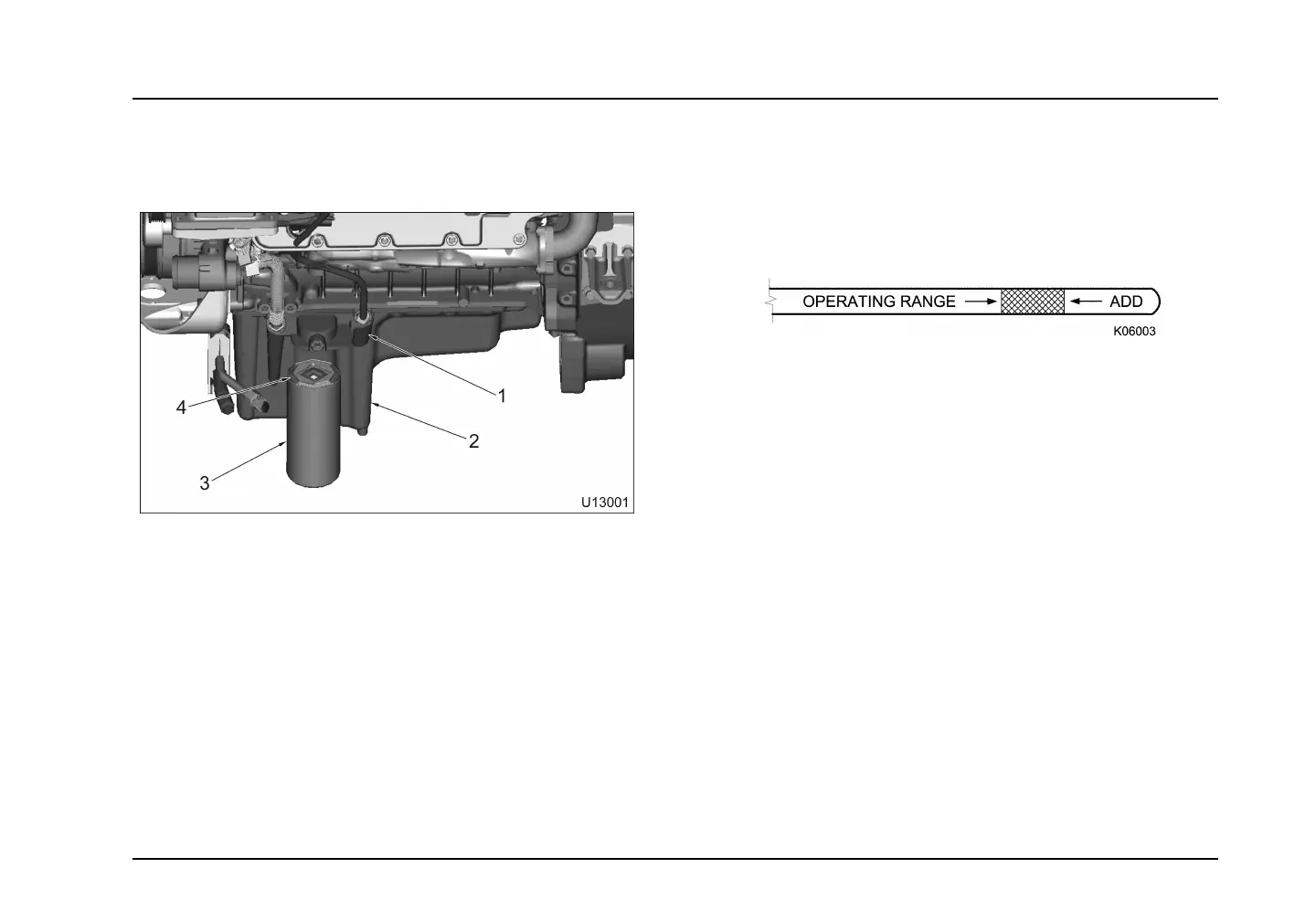

Figure31OilFilterRemovalAndInstallation

1.Oillterheader

2.Oilpan

3.Spin-onoillter

4.OillterO-ring

CAUTION:Topreventenginedamage,donotoverllwithoil.

13.Addcorrectoilviscosity.APICJ-4oilisrecommendedbut

CI-4isallowable.UseofCI-4engineoilwillreduceDPF

cleaninginterval.ForfurtherinformationseeMaintenance

ScheduleandServiceProcedureschart(page63).Addoil

throughtheengineoillltube.

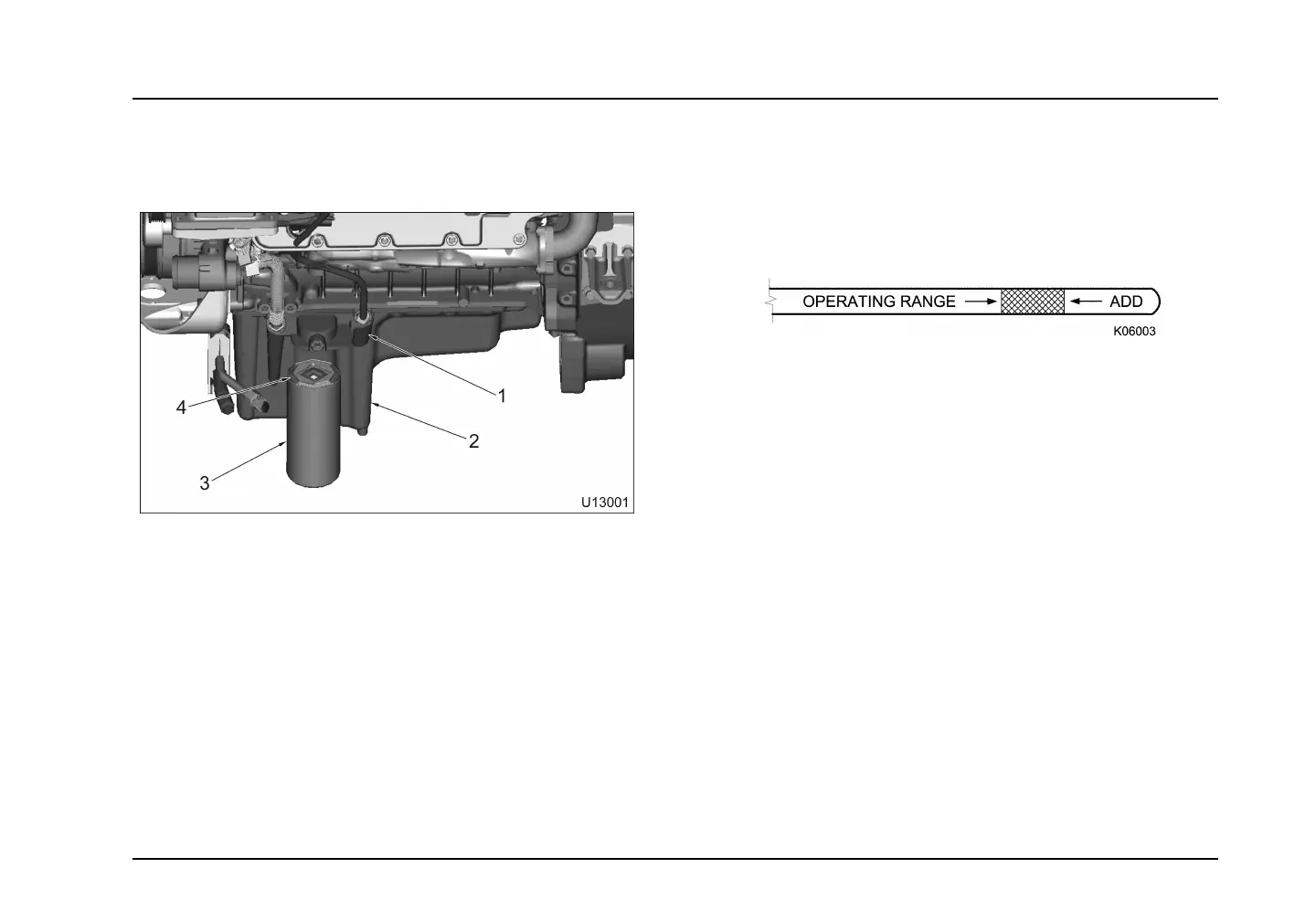

Figure32OilLevelGauge(Typical)

14.Checkoillevelgauge.Oillevelmustbewithinthe

crosshatchedoperatingrangeonthegauge.

15.Startengineandrunatlowidle.

16.Checkreadingonoilpressuregauge.

•Minimumlubeoilpressureis12psi(83kPa)@700

rpm.

•Ifthereisnogaugereading,shutenginedown

immediately.Checkforoillteranddrainplugleaks.

•Letenginerununtiloperatingtemperatureisreached.

Checkforleaks.

17.Shutdownenginefor5minutes.

CAUTION:Topreventenginedamage,donotoverllwithoil.

Page75

Loading...

Loading...