14

INSTALLING DECODERS

Read the following section on decoders before starting. There are shortcuts to temporary

installations of the other components, but do not shortcut the decoder. We recommend

you get your first decoder installed by a dealer or locomotive manufacturer just so you

have a good example of how it’s done.

The most important part of a successful decoder installation is proper isolation of

both

motor brushes from the track so that they are driven only by the decoder. Failure to

isolate will definitely damage the decoder. Damage caused by failure to isolate the motor

is not covered by the guarantee or warranty.

We find it preferable to mount the decoder with 1/2" wide 3M photo-mount double sided

foam tape (we get ours at the local supermarket).

Before test running your newly converted locomotive on full power double check your

wiring to make sure the motor is fully isolated and that there are no pinched or broken

wires. We see many decoders returned due to wires getting pinched between the body

shell and frame causing shorts.

Due to the high in-rush current of incandescent grain-of-wheat type bulbs (about 10

times the normal operating current) we have rated the decoder function outputs at

100mA each. We recommend Miniatronics part number 18-014-10 (2.4mm diameter 14

volt/30mA) bulbs for good results. If you are running higher voltages you will need to use

16 or 18 volt bulbs.

If you need to use higher current lamps (50-150mA) we recommend a 22 ohm 1/4 Watt

resistor in series with each bulb (this will also greatly extend bulb life). The function

outputs are rated at 150mA continuous if used with LEDs or other low in-rush devices.

Always make sure the motor is isolated from the frame. Always make sure metal

couplers are isolated from the frame.

Note 1: The function common (blue wire) is the positive lead providing rectified DC voltage. If you

elect to NOT use the common, power the light or other device from either track power pickup for

half-wave operation (approx. 1/2 voltage).

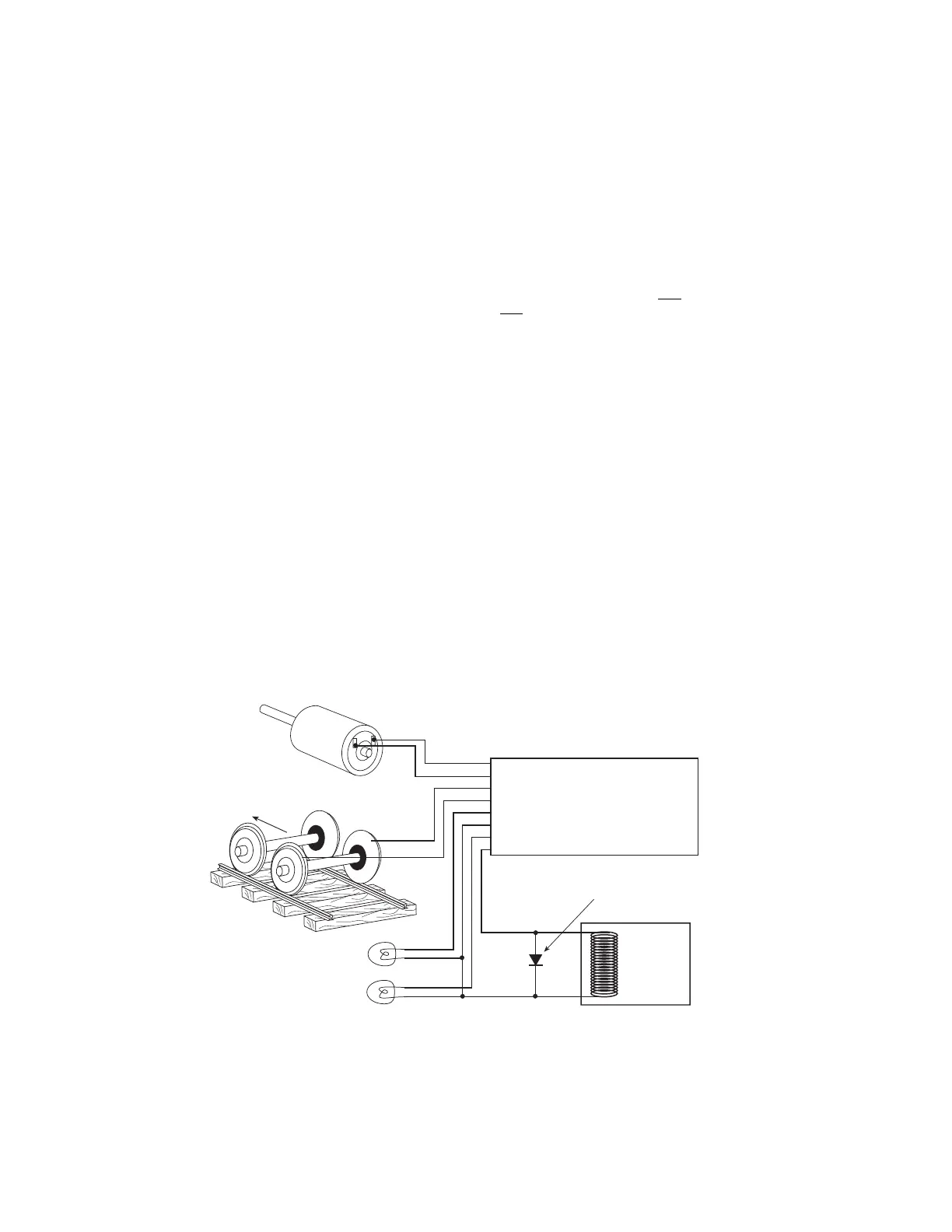

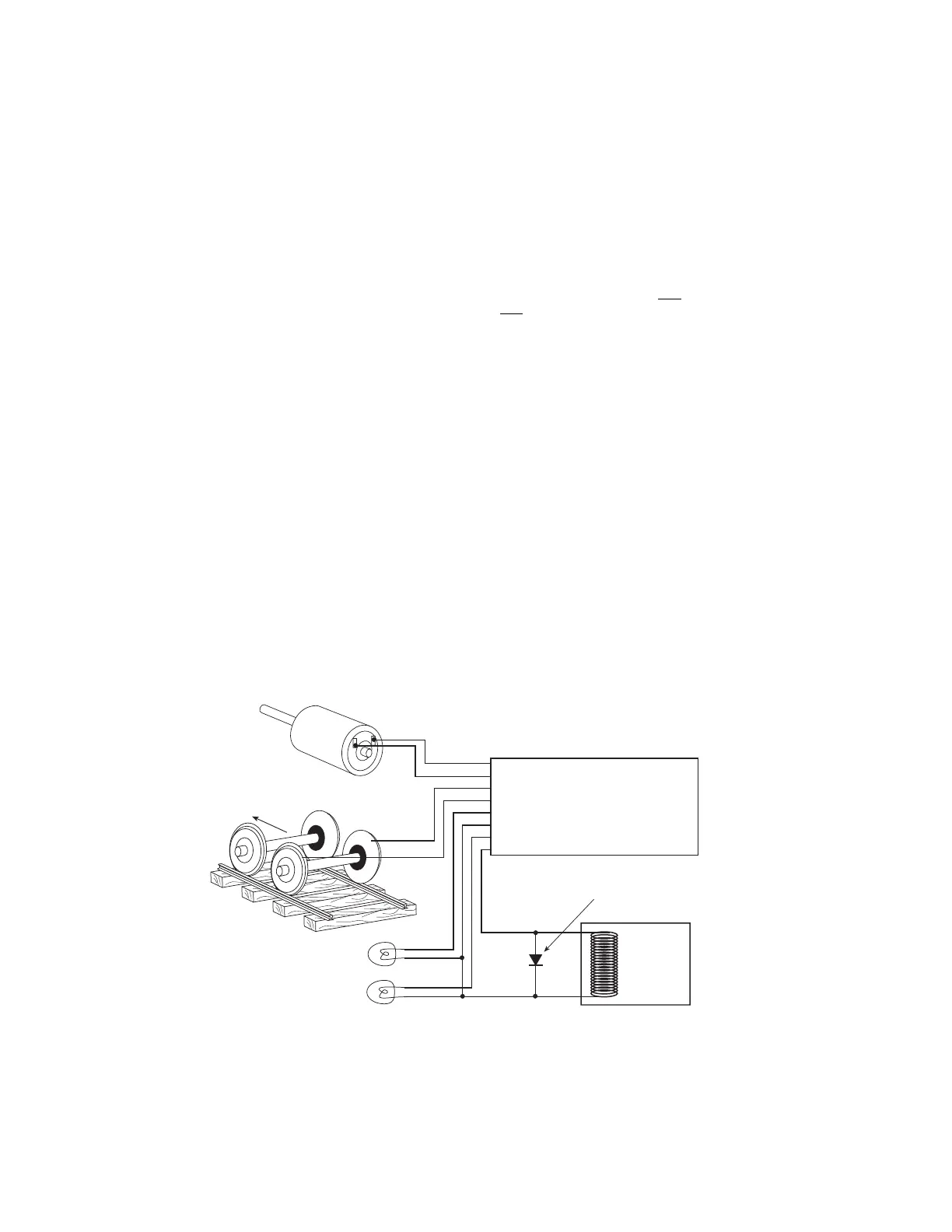

Relay, Smoke

unit, etc.

-

+

Note: If a function controlled device presents

inductive load (such as a relay), always use

a suppression diode (such as 1N4004 or 1N914)

across the device.

Motor -

Motor +

Right Track Power Pickup

Left Track Power Pickup

Forward Light

Light or Function Common (see note 1)

Reverse Light

Function 1 (not on all decoders)

Gray

Orange

Red

Black

White

Blue

Yellow

Green

Blue

Left Rail

Firemans Side

Right Rail

Engineers Side

Motor

WARNING: To prevent decoder damage,

ALWAYS make sure the motor brushes are

properly isolated before applying power.

Forward

Loading...

Loading...