21

POWER BOOSTER

PB105 and PB110A CONNECTIONS, CONTROLS and

INDICATORS

Starting at the left side of

the front panel, each

terminal, socket, and

indicator is explained

below:

POWER

TERMINALS:

Input power from an

outside power source goes

into the PB-105 via the left most two screw terminals of the four terminal black connector.

Always measure the transformer voltage before connecting it to your PB-105. A booster

that has been ‘over voltaged’ will result in catastrophic booster failure and void the

warranty (we can diagnose and determine if this has happened).

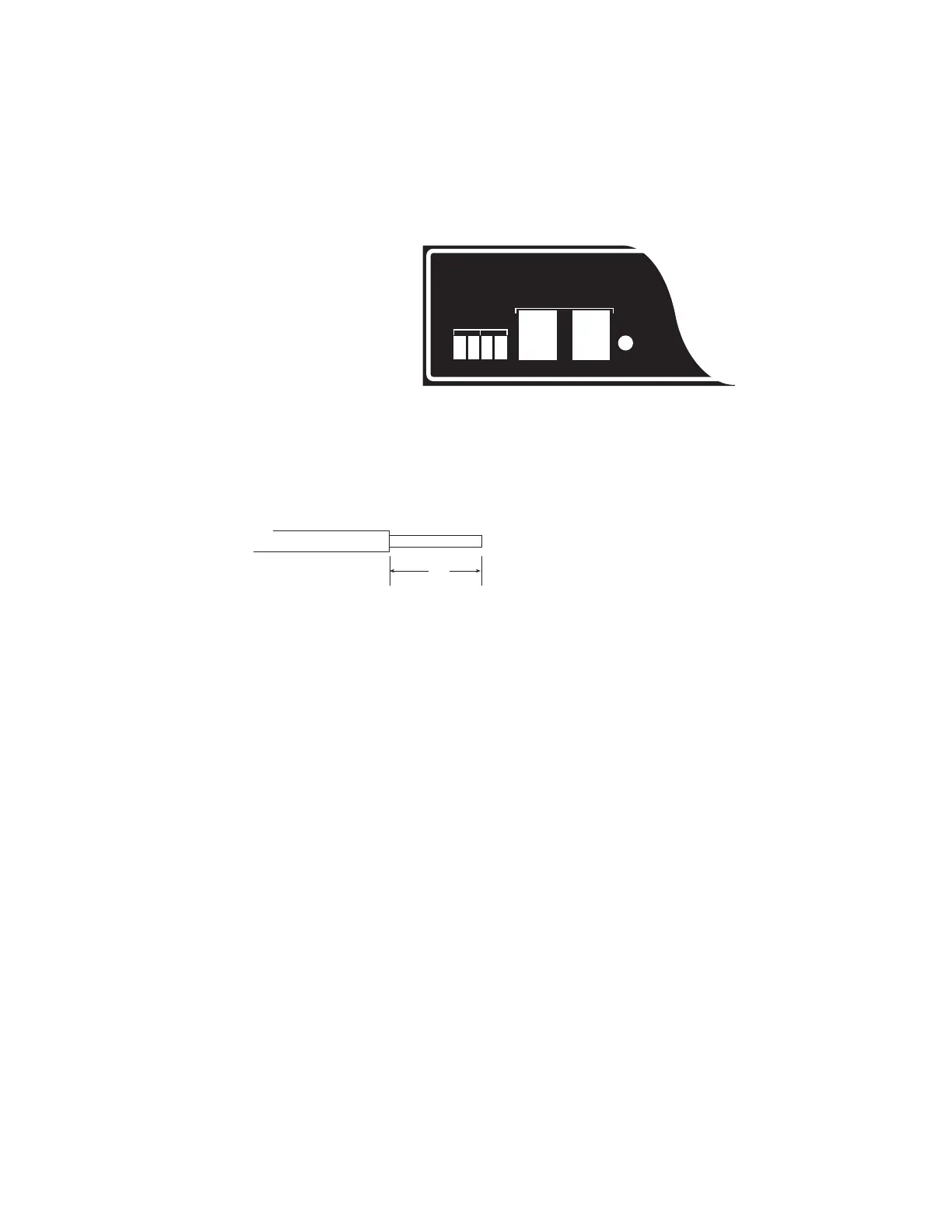

The screw terminals of the black connector are designed to accept wires up to #16 AWG

(2mm). Insulation should be stripped back

1/4 inch (6mm). Only stranded wire should

be used. If solid wire is used for track

power, make a splice joint to stranded wire

at some convenient place. Only stranded

wire should enter the terminal for reliable

contact. See the Basic Set Up of Your

System at the front of this manual.

If you wish to purchase additional connectors, you may call NCE Corporation to order

them.

THE TRACK TERMINALS:

NOTE: There are differences between the PB-105 and the PB110A boosters. See the

Basic Set Up Drawings at the front of this manual for the proper set up directions.

Wires from these terminals go to the track. If more than one booster is connected to the

layout, be sure the left track terminal on all boosters is consistently wired to the same rail.

This will ensure you have the same “phase” as you cross power district boundaries.

Always use wire of sufficient gauge (#16 minimum) to connect to the layout. Power

“drops” of #24 or #22 wire to a larger wire bus under the track are fine as long as the

length of each drop to the main bus is less than 12”.

Use of a smaller bus will prevent the booster from detecting a short circuit and may be a

fire hazard.

The voltage to the track is dependent on two factors: the power source input voltage

and the setting of the internal voltage adjustment, as discussed later. The DCC track

voltage for the Power Pro 5 Amp system is factory adjusted to the NMRA recommended

14 (+/- 0.1) volts for N, HO, and S scales. We do not recommend using a 5 Amp booster

with O-Scale as most O-Scale locomotives have stall currents in the area of 8 Amps

(Weaver, Red Caboose, P&D). For O-Scale usage we recommend our PB110A Ten Amp

power booster. The PH-10 system is factory set for 16 volts.

CONTROL BUS SOCKETS

The control bus sockets on the front of the booster are paired to allow wiring the control

signal coming from the command station to “daisy chain” through the booster. Use the

supplied cable to connect the booster to the command station’s CONTROL BUS socket.

The remaining (unused) socket on the booster can be used to connect to other boosters

POWER PRO

FROM

NCE Corporation

STATUS

CONTROL BUS

22VAC / 32VDC MAX.

POWER TRACK

16VAC / 28VDC MAX.

Insulation

Bare Stranded Wire

1/4

Loading...

Loading...