65

Figure 4.12 Plate holders come forward when door is open and OpenSPR-XT software is running.

The sampling needle is controlled by a robotic arm which is programmed to position the needle

into the selected well of interest in either of the 96-well plates. The syringe will automatically

draw the sample into the needle and the sample will be injected into the fluidics block of the

OpenSPR unit via the injection valve and exposed to the sensor surface upon the software

command.

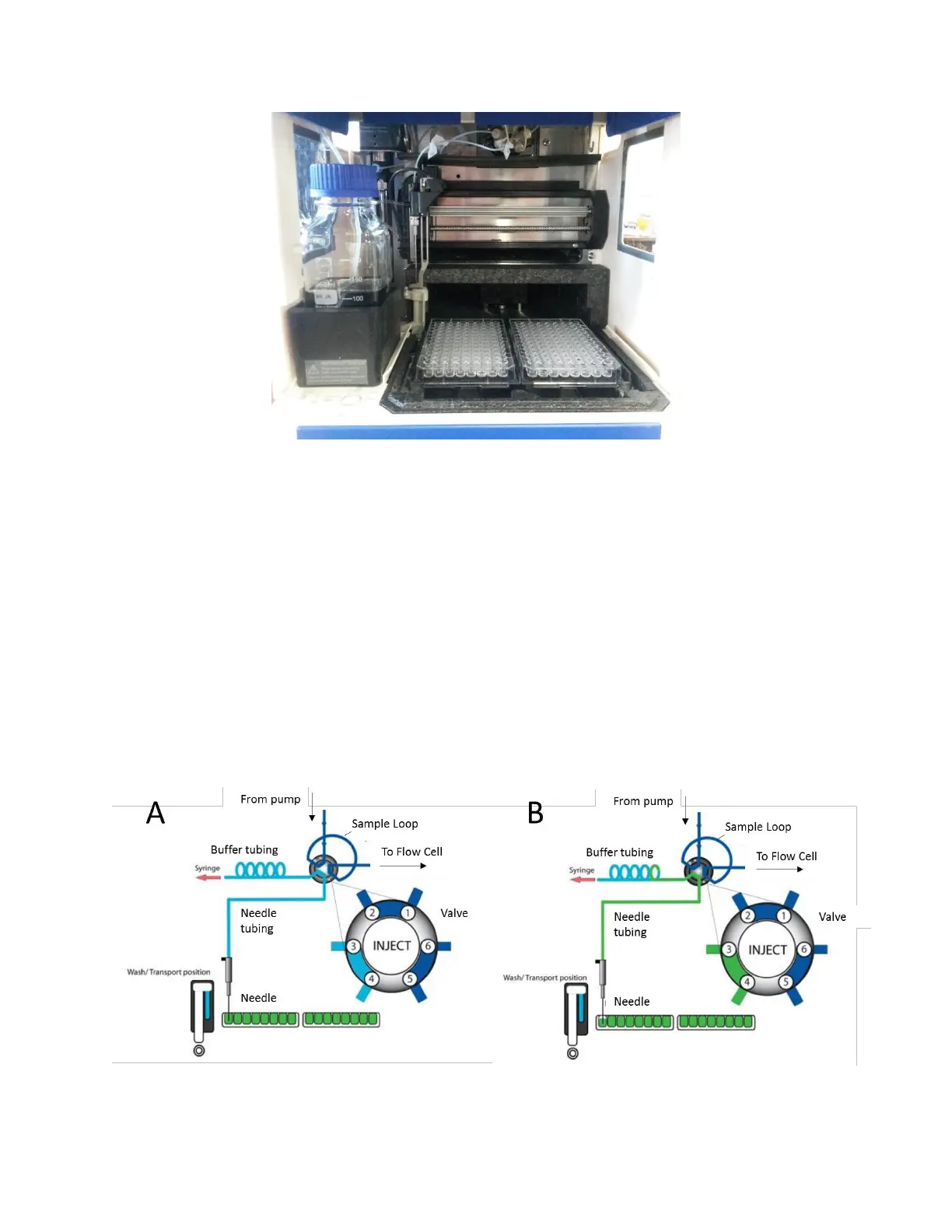

The sample is introduced into the Flow Cell microchannel and is exposed to the Sensor Chip in a

controlled manor using a 6 port Injection Valve located inside the sample compartment. One port

of the valve is connected to the Sampling Needle. The buffer and needle tubing are initially filled

with the wash solution to prevent cross contamination between samples. Sample is initially

drawn in by the needle to flush the sample lines to avoid mixing with the wash solution [Figure

4.13]. This is performed when the Valve is in the INJECT position.

Figure 4.13 A) Initial state - needle tubing is filled with wash solvent. B) Needle aspirates flush volume of sample to remove wash

solvent.

Loading...

Loading...