SERVICE MANUAL

11

www.norcold.com

face of the apper assembly. The surface of the apper assembly

should be slightly warm to the touch.

If the apper surface feels cold to the touch or is wet, troubleshoot

the heater as follows:

1. Check for any bent, broken or missing spring pins.

2. Check the door alignment. If needed, align the door so that

all of the spring pins make full contact with the center of the

contacts in the cabinet.

3. Check the heater resistance. Resistance reading should be

between 26 ohms and 31 ohms.

4. Replace the apper assembly if the heater is open, shorted, or

if the resistance is not between 26 ohms and 31 ohms.

Temperature Monitor Control (TMC)

The purpose of the temperature monitor control is to prevent dam-

age to the cooling unit due to an overheating condition in the boiler.

An overheating condition may be caused by one or a combination

of the following:

■ Insufcient or obstructed ventilation.

■ Inadequate installation in enclosure.

■ Heat deector cap blocked by insulation.

■ Heat deector cap jammed against ue opening.

■ Exceeding off-level limits.

■ Cooling unit blockage.

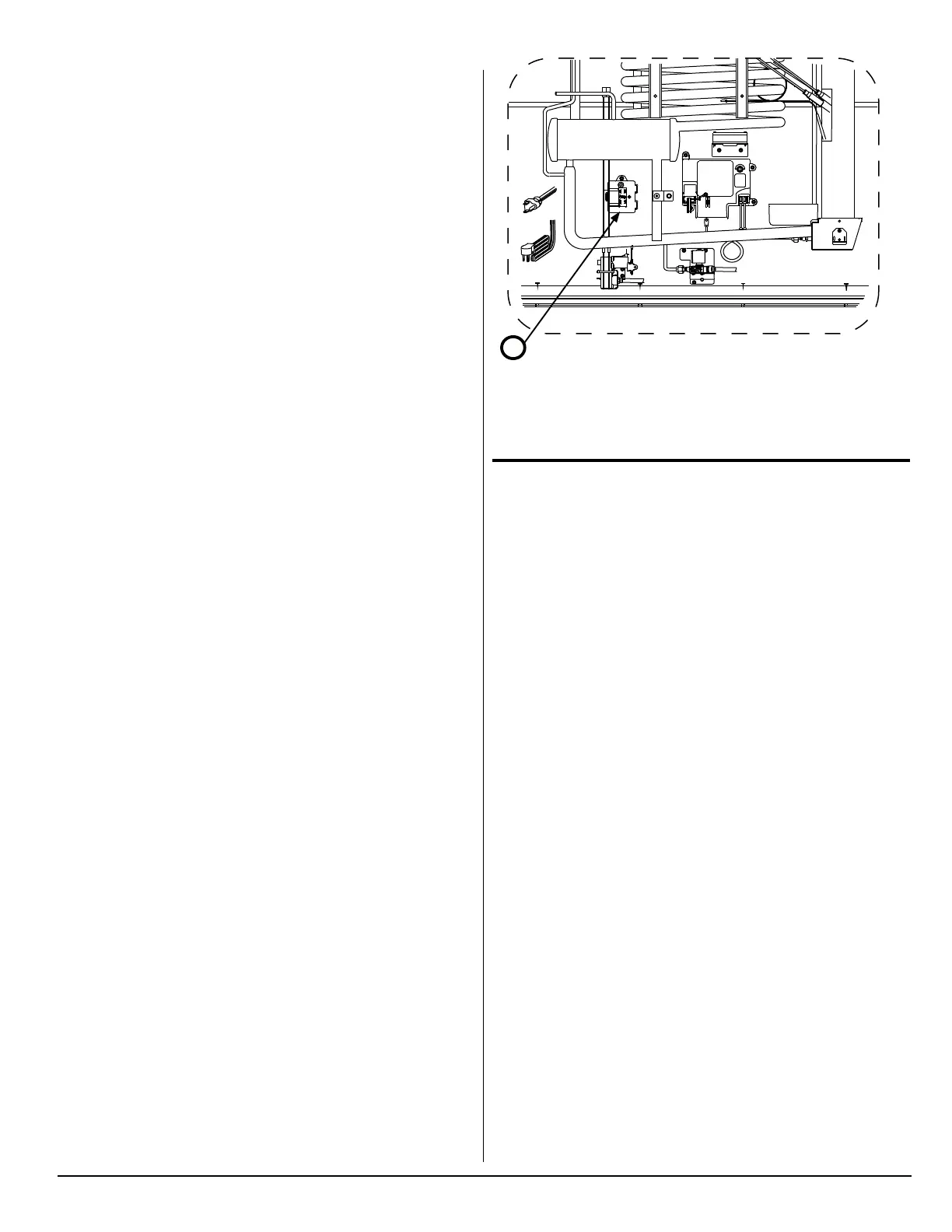

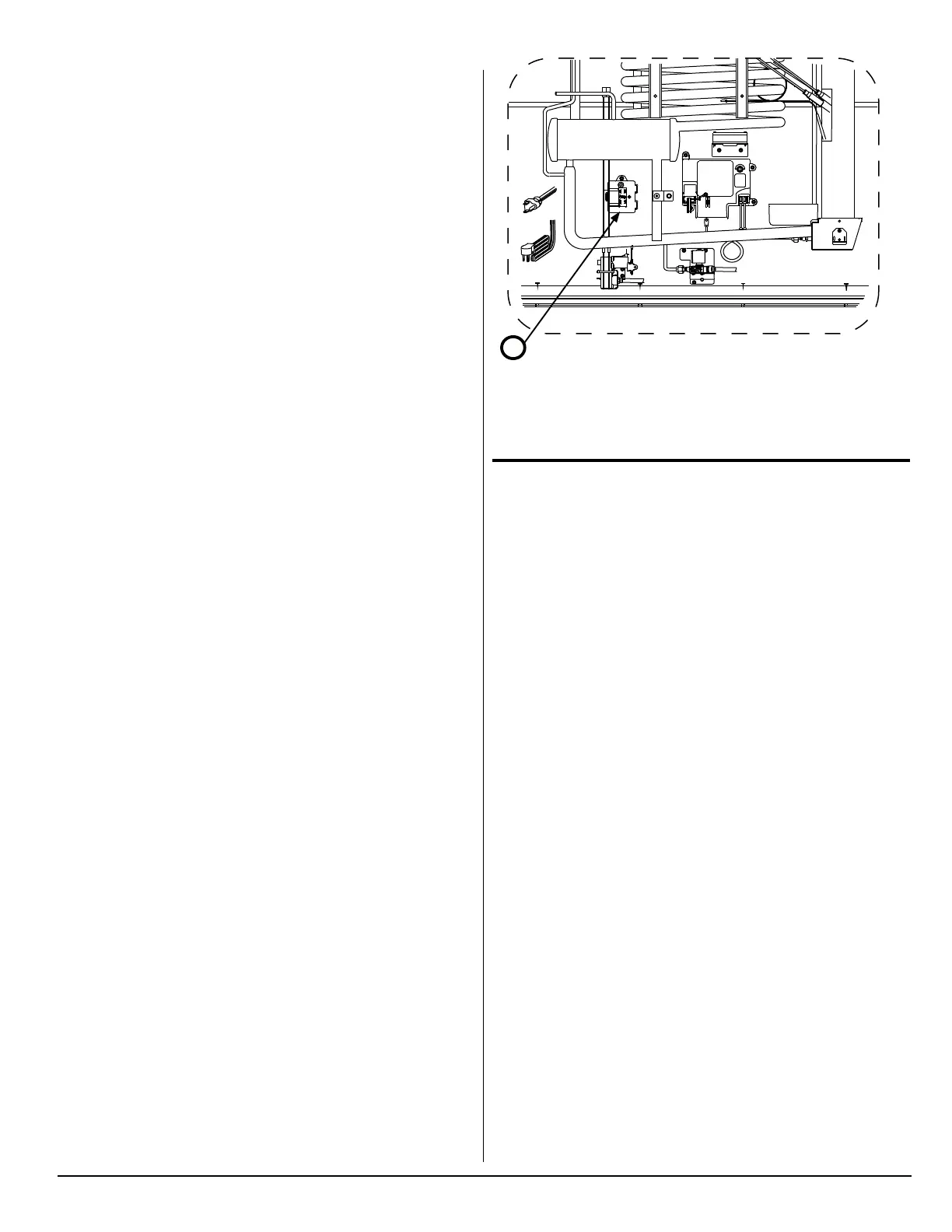

The temperature monitor control [326] acts as a temperature

supervising device (See Fig. 9). It uses a thermocouple, which is

positioned on the boiler, to provide the best possible monitoring of

temperature.

If the temperature of the boiler rises to an abnormal level, the high

temperature monitor opens to prevent the boiler from overheating.

The controls are programmed to detect when the monitor is open.

If the switch is open or not connected to power board terminals

LIMIT IN and LIMIT OUT, the controls:

■ Display fault code “LI” “oP”.

■ Stop AC and propane gas operation.

Electrical Components, cont’d.

Fig. 9 - Temperature monitor control

326

NOR000212A-1

Preventative Maintenance

An annual maintenance check is strongly recommended:

■ Leak test the gas lines.

■ Check combustion seal; repair or replace, if necessary (Visual

check without removing the refrigerator.).

■ Inspect or clean the burner or burner orice.

■ Check/adjust the electrode spark gap.

■ Insure the spark electrode tip is clean and that the electrode is

securely attached to the burner bracket.

■ Check/adjust AC and DC voltages and propane gas supply

pressure.

■ Check the gas safety valve (see procedure in this manual).

■ Insure that area around the burner and controls is free of de-

bris, oily rags, etc.

■ Inspect the controls, piping and wiring to insure that they are in

good condition.

THESE MAINTENANCE PROCEDURES MUST BE PERFORMED BY A

QUALIFIED SERVICE PERSON.

NORCOLD CANNOT ACCEPT RESPONSIBILITY FOR REPAIRS,

ADJUSTMENT, OR MAINTENANCE PERFORMED BY OTHER THAN A

QUALIFIED DEALER OR SERVICE CENTER.

Loading...

Loading...