MF 64

Author: Donato Gavino Murru donato.gavino.murru@omgitaly.com Pag. 163 a 179

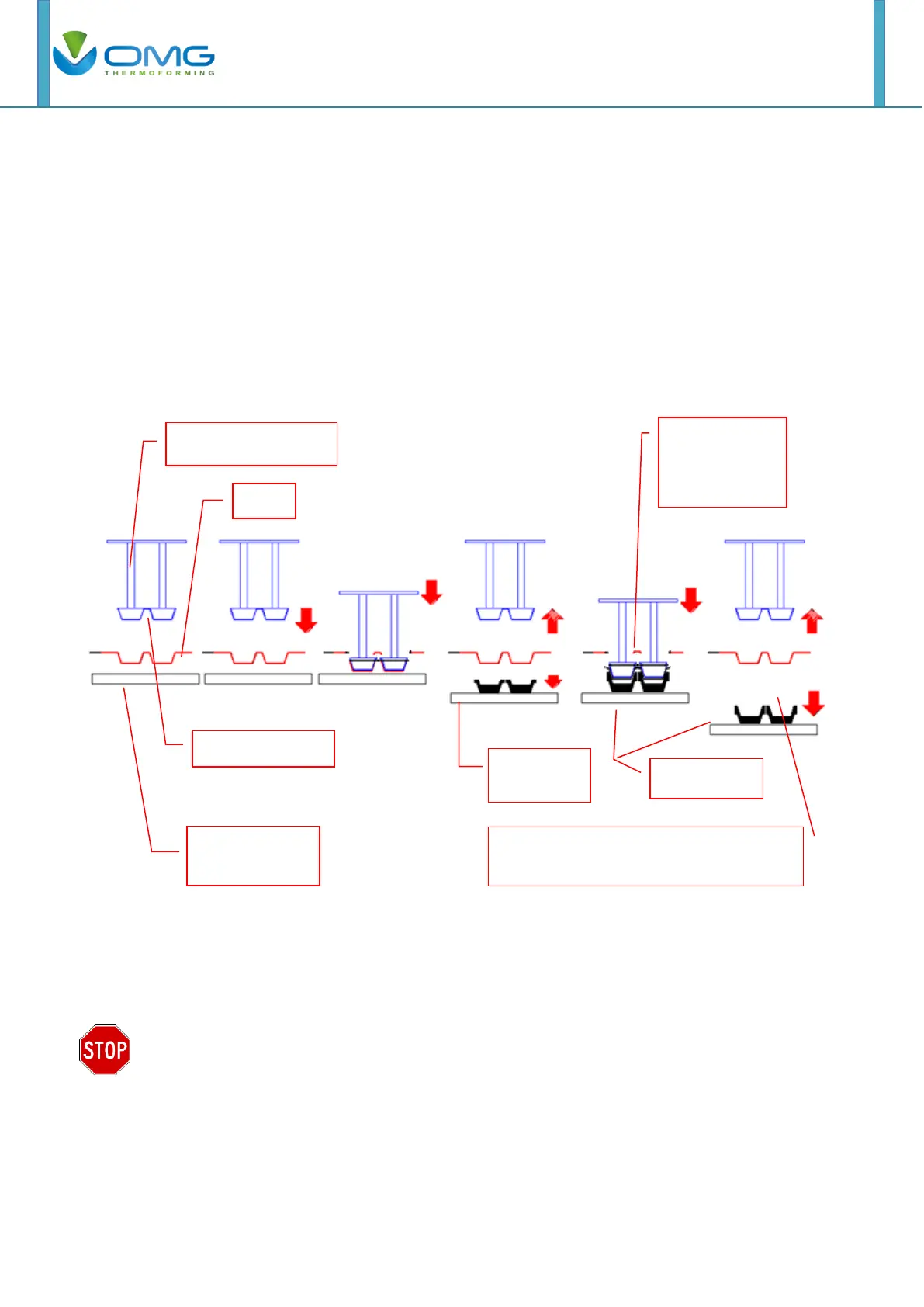

Stacker mode: type G

This mode is referring to downward stacking, in which the pieces are stacked using conveyor and

upperand lower stacker.

On the upper stacker is mounted the pusher, on the lower stacker is mounted the web tool locking.

(All tooling's provided by customer). Any kind of mold produces a different number of shapes, for

which it is necessary to change the tools.

The toolings that are mounted on the upper and lower stacker are used to keep the external scrap

web clamp tight while the upper stacker pushes the product on the conveyor.

The products accumulated on conveyor are pushed out when counter finish.

The amount of additional travelling setting is located in the lower stacker page on the touch screen.

Pay attention to adjust the working positions of flat bars properly. Not

doing so may result in injuries or mechanical damage.

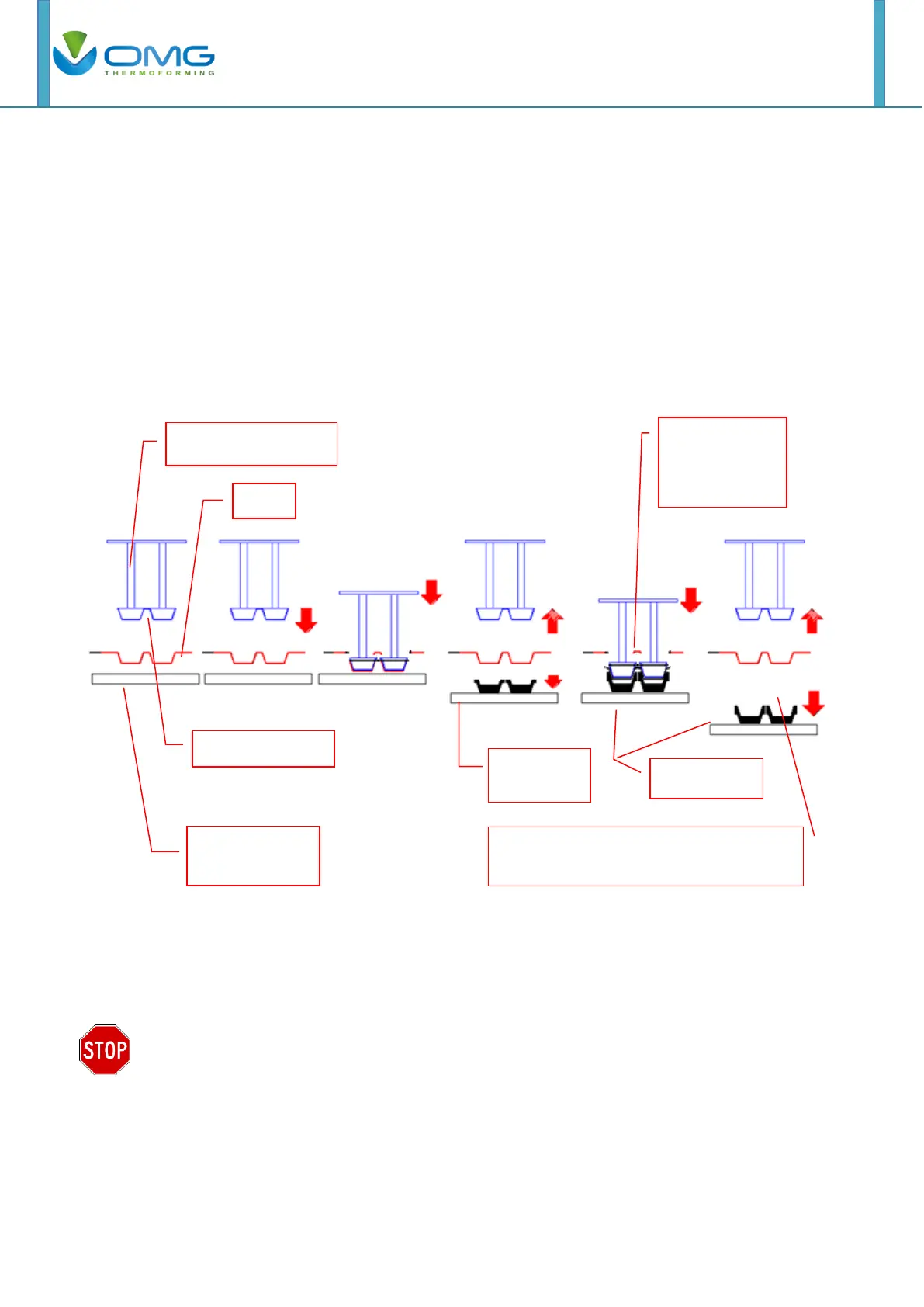

When the stacking counter movement is completed, it is indispensable to extract the piles from the

blades. For this purpose, there is a pneumatic system that pushes the piles out of the stacker, and

pushes them on a table or conveyor located at the exit of the machine.

Extraction position with the counter

“on” up the additional level.

Taking out

the piles to

Conveyor.

Loading...

Loading...