89

Configuration of Function Blocks Section 3-1

Connecting analog

signals (variables)

and accumulated

value signals

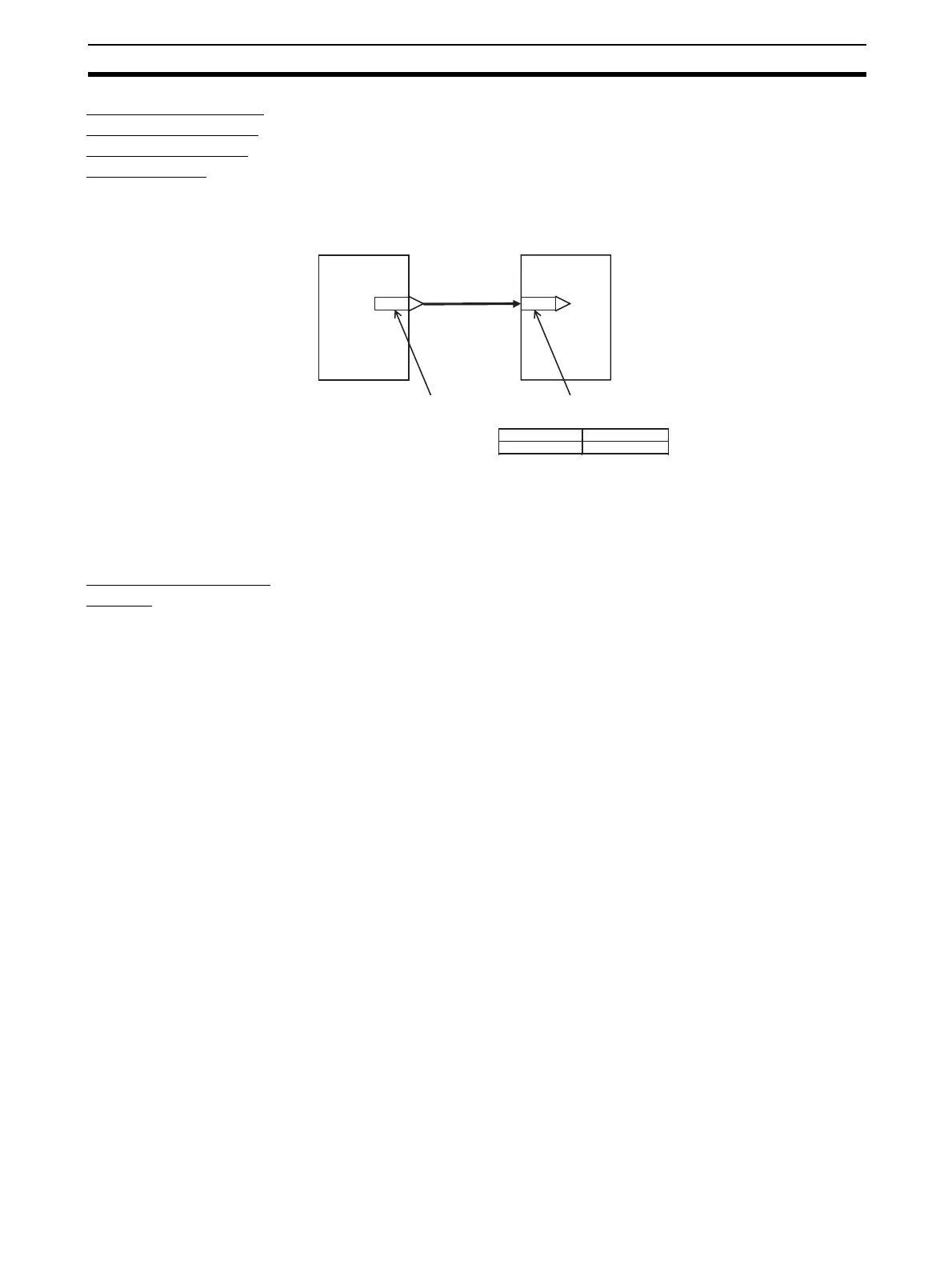

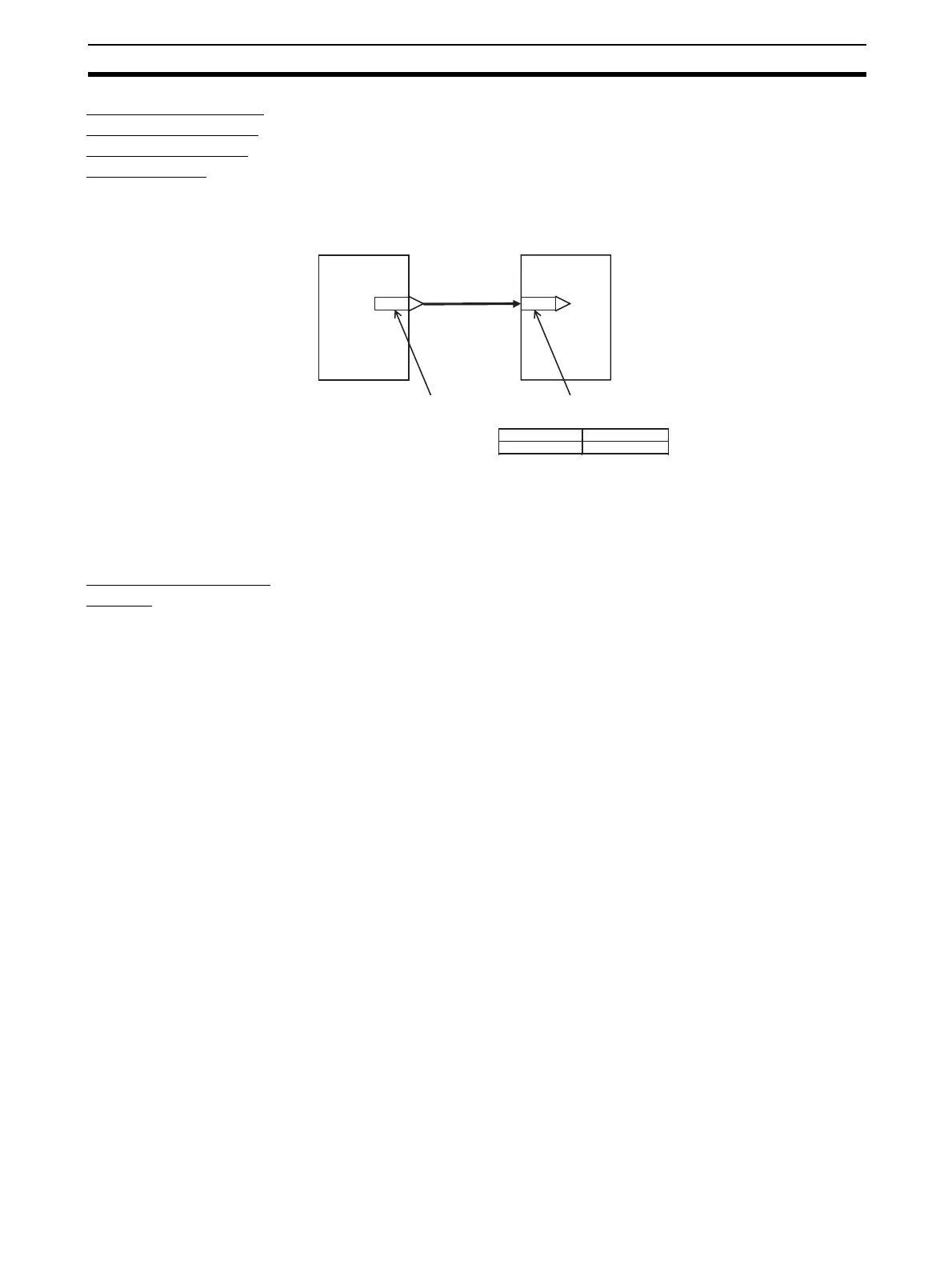

Specify in the analog input ITEMs which analog output ITEM and its block

address are to be used to introduce analog signal function blocks on the input

side.

Example To introduce ITEM006 (PV) of the Basic PID block of block address 001 from

ITEM011 (Y1) of the Square Root block of block address 100.

Note Connection of analog signals or accumulated value signals can be executed

on CX-Process Tool separately from setting of ITEM data as wiring of function

blocks. (Connection of analog signals or accumulated value signals can also

be set as ITEM data.)

Connecting contact

signals

Contact signals are connected via the Sequence Table block (Block Model

302), Step Ladder Program block (Block Model 301), or the Contact Distribu-

tor Block (Block Model 201). *1

Specify both contact inputs (Sequence Table block, Step Ladder Program

block, or Contact Distributor block to specified function block) and contact out-

puts (specified function block to Sequence Table block, Step Ladder Program

block, or Contact Distributor block) in the Step Ladder Program block (Block

Model 301) or the Contact Distributor Block (Block Model 201). Do not specify

these contact signals to ITEMs in the specified function block.

Note On CX-Process Tool, connection of contact signals is executed at setting of

ITEM data.

∗1: As an exception, with some of the ITEMs (PV error input of ITEM018 and

MV error input of ITEM090 of the Basic PID block or the Advanced PID

block) contacts are input specified as the source designation.

011 006

Block address: 100 Block address: 001

Y1

PV

Block address: 001

ITEM number Data

006 100011

Basic PIDSquare Root

Loading...

Loading...