177

Simple Example of Use Section 4-1

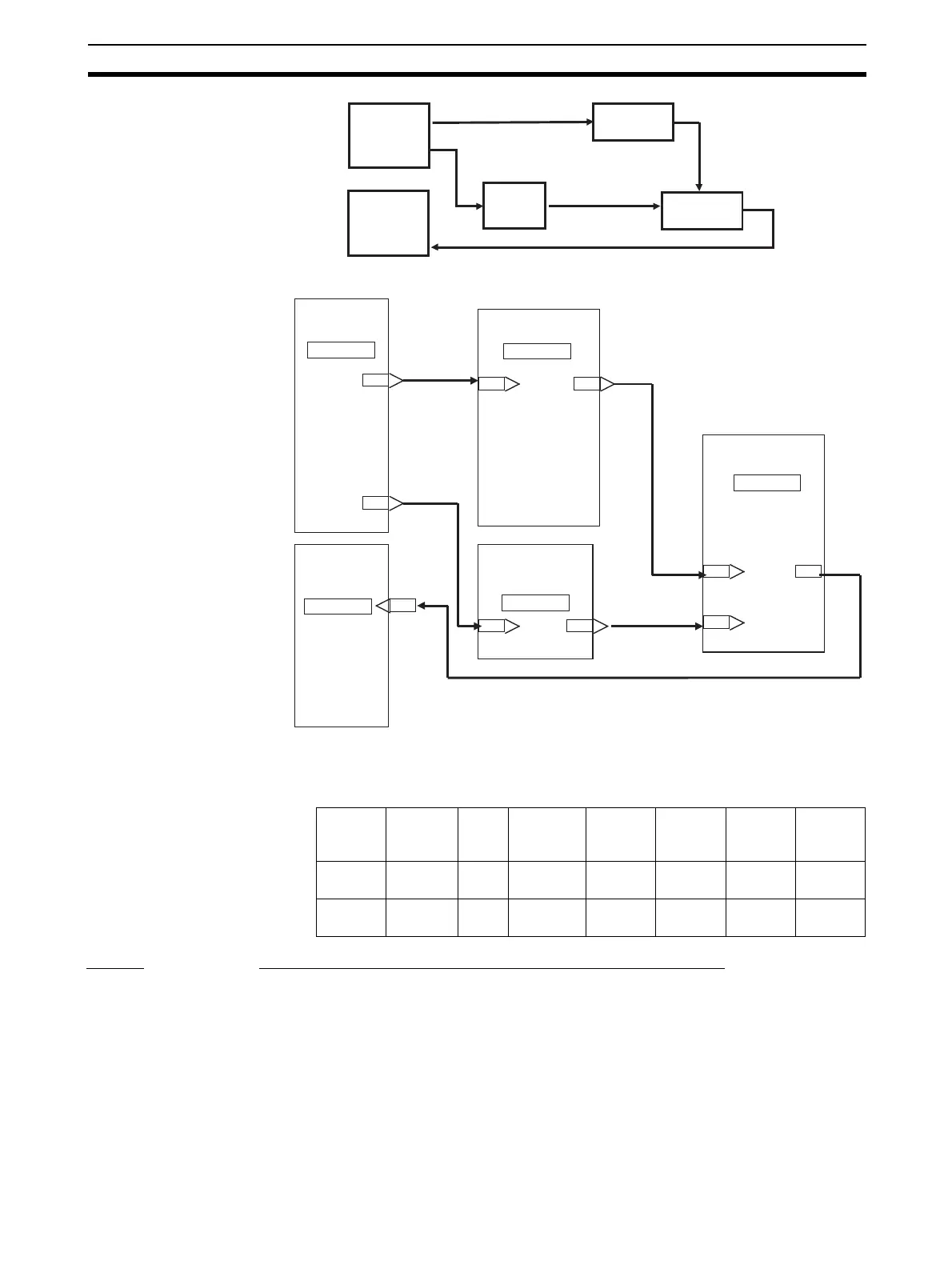

4. Decide on the function block system configuration.

5. Decide on the data to be monitored and manipulated by SCADA software,

a PT, etc.

The following table shows the function blocks to be monitored.

Step 2 Preparing Function Block Data on CX-Process Tool

1,2,3... 1. Set up and start CX-Process Tool.

2. Set the System Common block data.

Set the specifications common to each function block in the System Com-

mon block (Block Model 000). The ITEMs in this block must be set as the

initial settings when the Loop Control Board is to be used.

PV1

AI 4-point

Block Model 586

Basic PID

Block Model 011

Basic PID

Block Model 011

MV1

PV2

RSP

MV2

Square Root

Block

Model 131

AO 4-point

Block Model 587

AI 4-point

< Block Model 586>

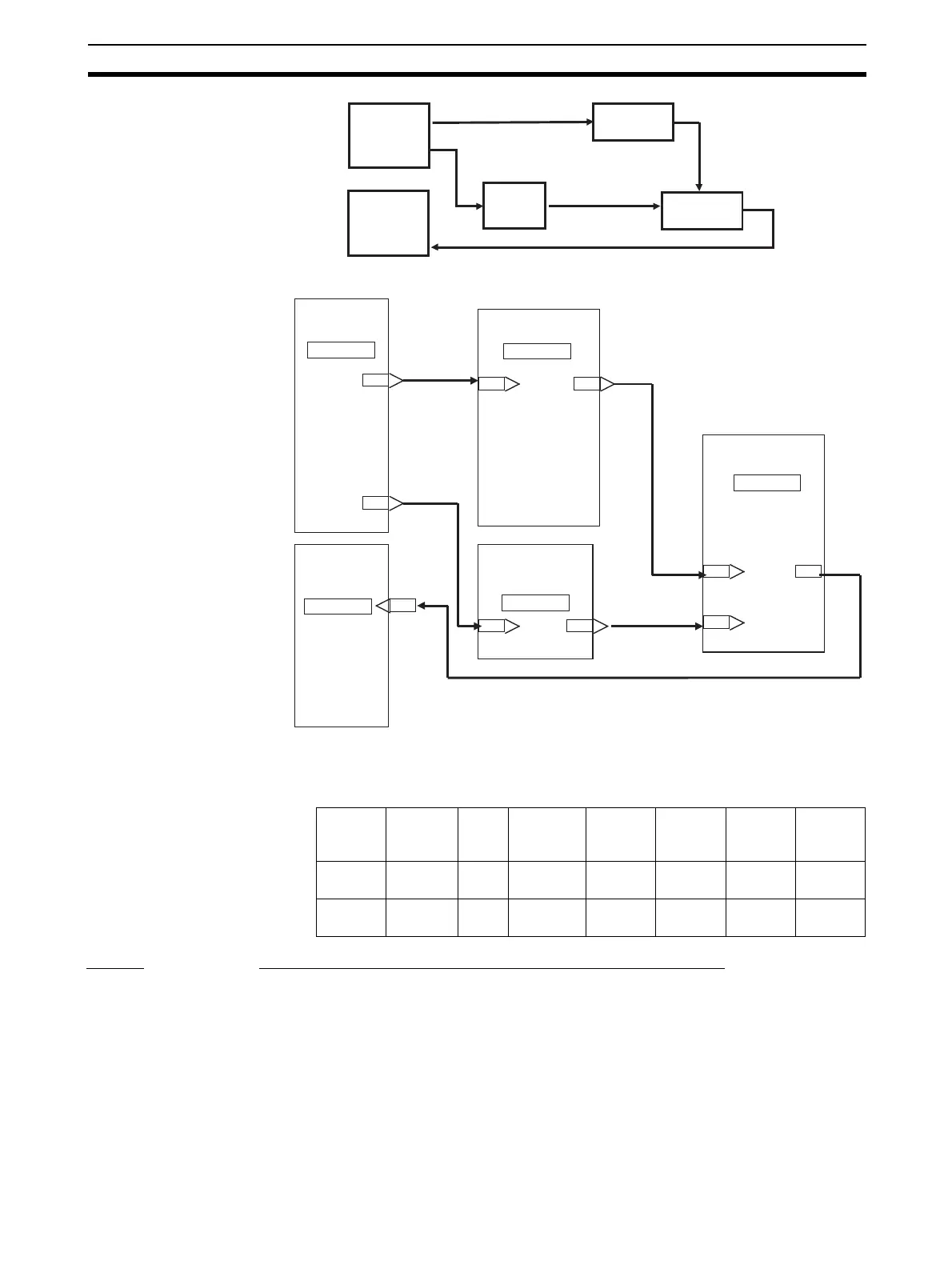

021

PV1

006

PV2

Basic PID

< Block Model 011>

022

021

RSP2

006

Basic PID

<Block Model 011>

Address 001

087

MV1

021

007

Square Root

< Block Model 131>

011

MV1

087

AO 4-point

<Block Model 587>

Address 901

Address 902

Address 101

Address 002

Block

address

Function

block

name

Tag

No.

Tag

comment

High

limit

(RH)

Low

limit

(RL)

Unit

(UNIT)

Decimal

point

(DP)

001 Basic

PID

PID1 0 300 °C 1

002 Basic

PID

PID2 0 400

m

3

/HR

1

Loading...

Loading...