Version 4.0.2 dated 2019-4-3 Page 15Translation of the original instructions

BF20V | BF20L | BF20LD GB

BF20V_BF20L_BF20LD_GB_1.fm

OPTIMUM

MASCHINEN - GERMANY

®

1.10 Safety check

Check the drilling-milling machine in regular intervals.

Check all safety devices

before each operation,

once a week (with the machine in operation),

after every maintenance and repair work.

1.11 Personnel protective equipment

For certain work personal protective equipment is required.

Protect your face and your eyes: Wear a safety helmet with facial protection when performing

works where your face and eyes are exposed to hazards.

Use protective gloves when handling pieces with sharp edges.

Use safety shoes when you assemble, disassemble or transport heavy components.

Use ear protection if the noise level (inmission) in the workplace exceeds 80 dB (A).

Before starting work make sure that the prescribed personnel protective equipment is available

at the working place.

CAUTION!

Dirty or contaminated personnel protective equipment can cause diseases. Clean it each

time after use and once a week.

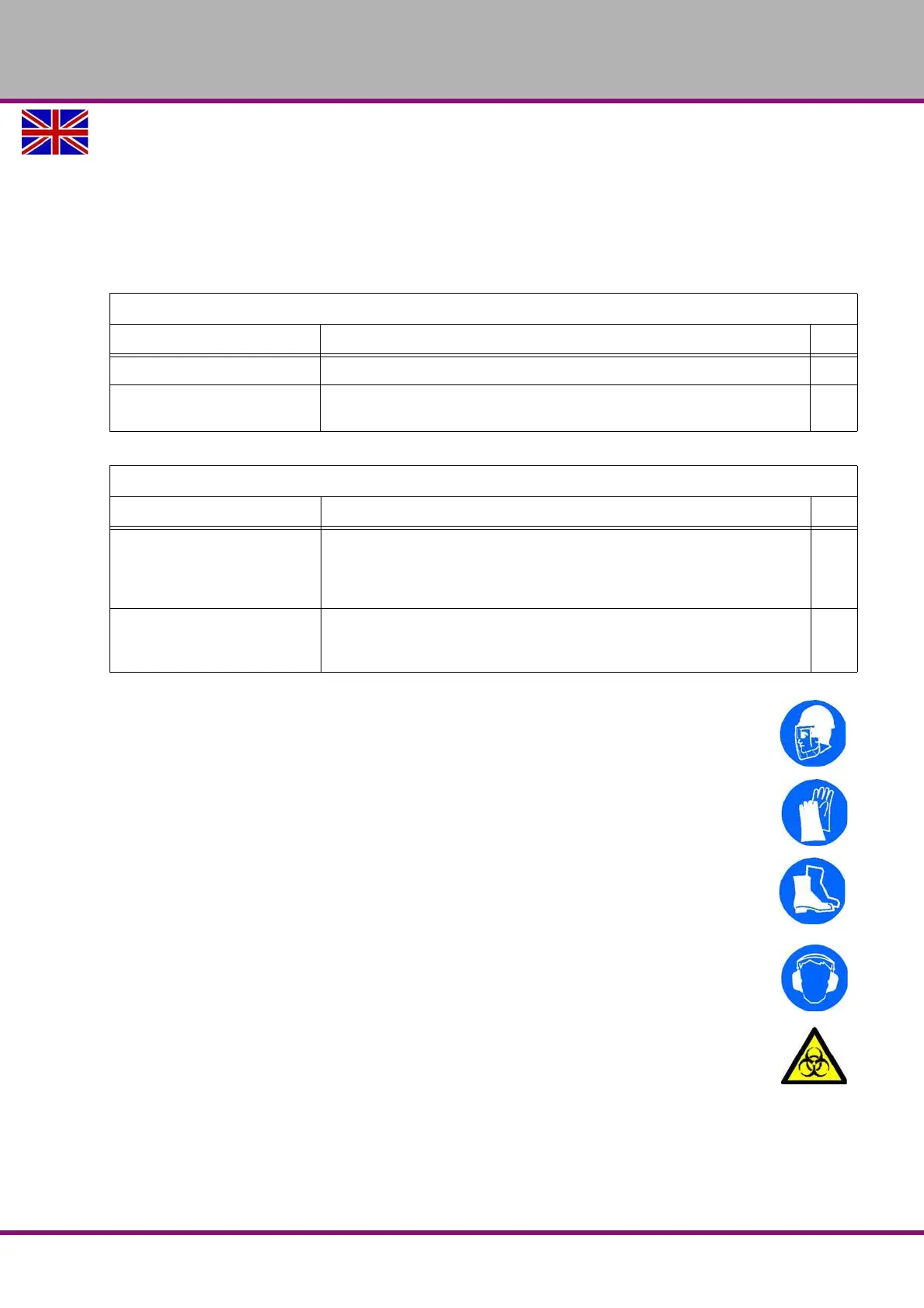

General check

Equipment Check OK

Protective covers Mounted, firmly bolted and not damaged

Signs,

Markings

Installed and legible

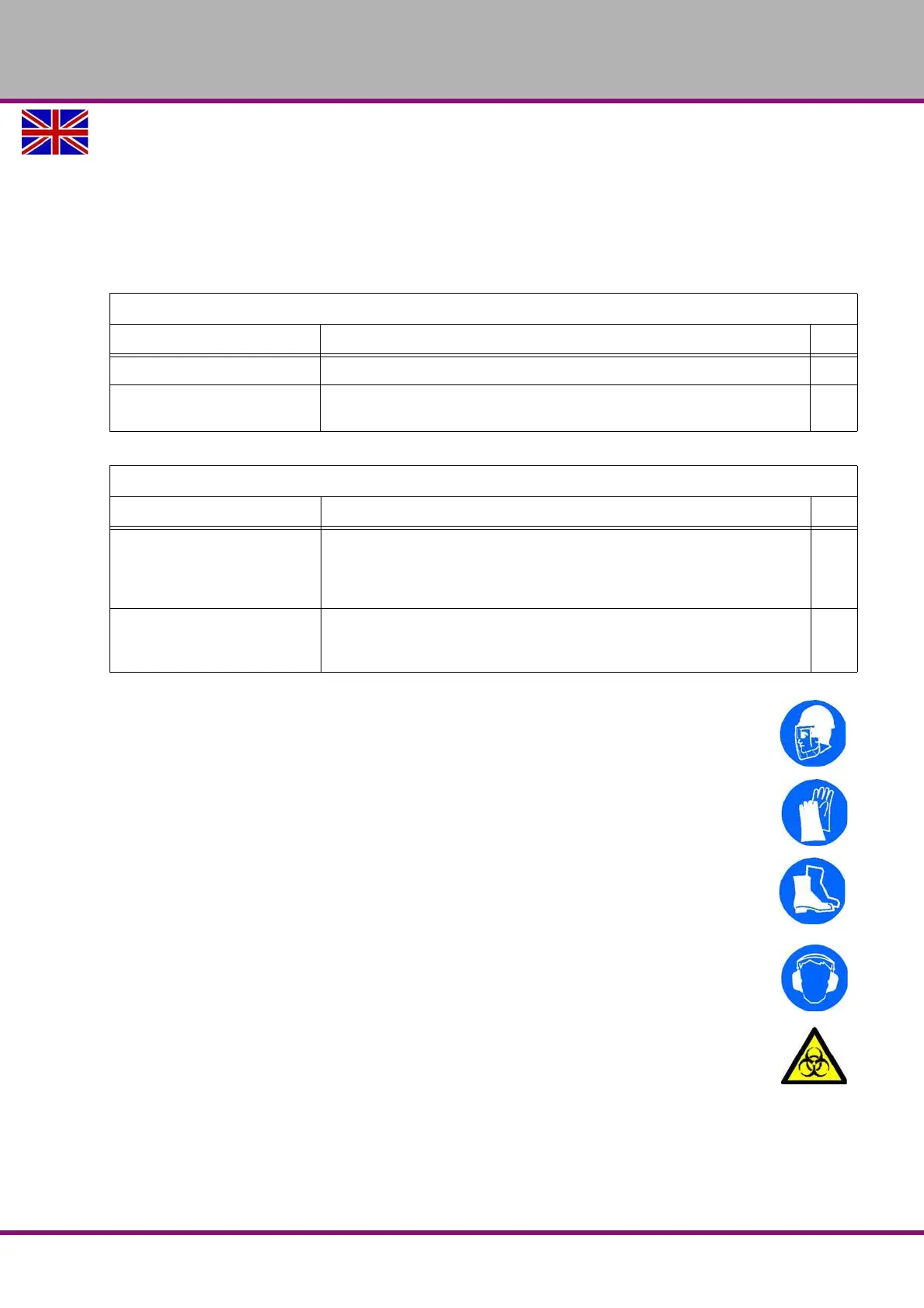

Functional check

Equipment Check OK

EMERGENCY-STOP push but-

ton

When the EMERGENCY-STOP button is activated, the drilling-milling

machine should switch off. Make sure that it is only possible to restart the

machine if the EMERGENCY STOP push button is unlocked and the ON

switch was activated.

Separating protective equip-

ment around the drilling milling

spindle

The drilling-milling machine may switch on only when the safety device is

closed.

Loading...

Loading...