Version 4.0.2 dated 2019-4-3Page 30 Translation of the original instructions

BF20V | BF20L | BF20LDGB

BF20V_BF20L_BF20LD_GB_4.fm

OPTIMUM

MASCHINEN - GERMANY

®

4.6 Clamping the workpieces

CAUTION!

Risk of injury caused by workpieces flying off.

The workpiece is always to be fixed by a machine vice, jaw chuck or by another

appropriate clamping tool such as for the clamping claws.

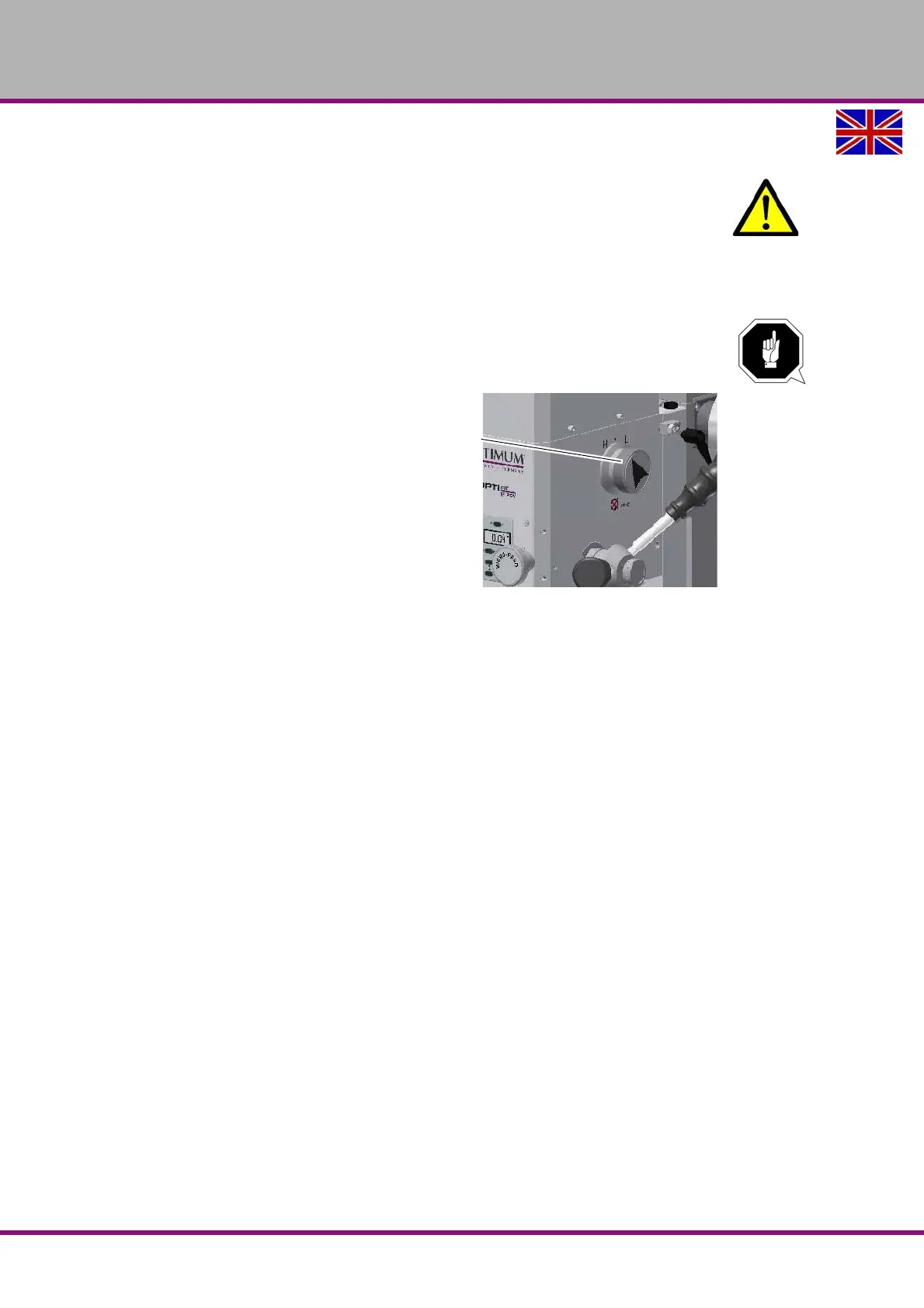

4.7 Changing the speed range

ATTENTION!

Wait until the drilling-milling machine has come to a complete halt, before performing

any changes on the gear switch.

Select gear level

H = rapid

L = low

Adjust the speed with the

potentiometer. The speed and

thus the cutting speed

depends on the material of the

workpiece, the milling cutter

diameter and the cutter type.

Img.4-6: Drilling and milling head

4.8 Selecting the speed

The correct speed is an important factor for milling. The speed determines the cutting speed by

which the cutting edges cut the material. By selecting the correct cutting speed, the service life

of the tool is increased and the working result is optimized.

The optimum cutting speed mainly depends on the material and on the material of the tool. With

tools (milling cutters) made of hard metal or ceramic insert it is possible to work with higher

speeds than with tools made of high-alloy high speed steel (HSS). You will achieve the correct

cutting speed by selecting the correct speed.

In order to determine the correct cutting speed for your tool and for the material to be cut you

may refer to the following standard values or a table reference book (e.g. Tabellenbuch Metall,

Europa Lehrmittel, ISBN 3808517220).

The required speed is calculated as follows:

n = speed in min

-1

(revolutions per minute)

V = cutting speed in m/min (meter per minute)

d = tool diameter in m (Meter)

Selector switch gear stage

H = rapid

L = low

Loading...

Loading...