Version 4.0.2 dated 2019-4-3Page 44 Translation of the original instructions

BF20V | BF20L | BF20LDGB

BF20V_BF20L_BF20LD_GB_5.fm

OPTIMUM

MASCHINEN - GERMANY

®

6.2 Inspection and maintenance

The type and level of wear depends to a large extent on the individual usage and operating

conditions. For this reason, all the intervals are only valid for the authorised conditions.

Interval Where? What? How?

Start of work,

after every

maintenance or

repair work

Drilling-milling machine

"Safety check“ on page 15

Start of work,

after every

maintenance

or repair work

Dovetail guides

Oiling

Lubricate all slideways.

Every week

Cross table

Oiling

Oil all bare steel surfaces. Use an acid-free oil, e.g.

weapon oil or motor oil.

As required

Spindle nuts

Readjusting

An extended clearance in the spindles of the cross table can be

reduced by readjusting the spindle nuts. Refer to spindle nuts posi-

tion 66 and 71

The spindle nuts are readjusted by reducing the thread flanks of the

spindle nut by means of a regulating screw. Due to the readjustment

it is necessary to check if a smooth movement over the whole travel

is still given, otherwise the wear is considerably increased due to

the friction between the spindle nut and the spindle.

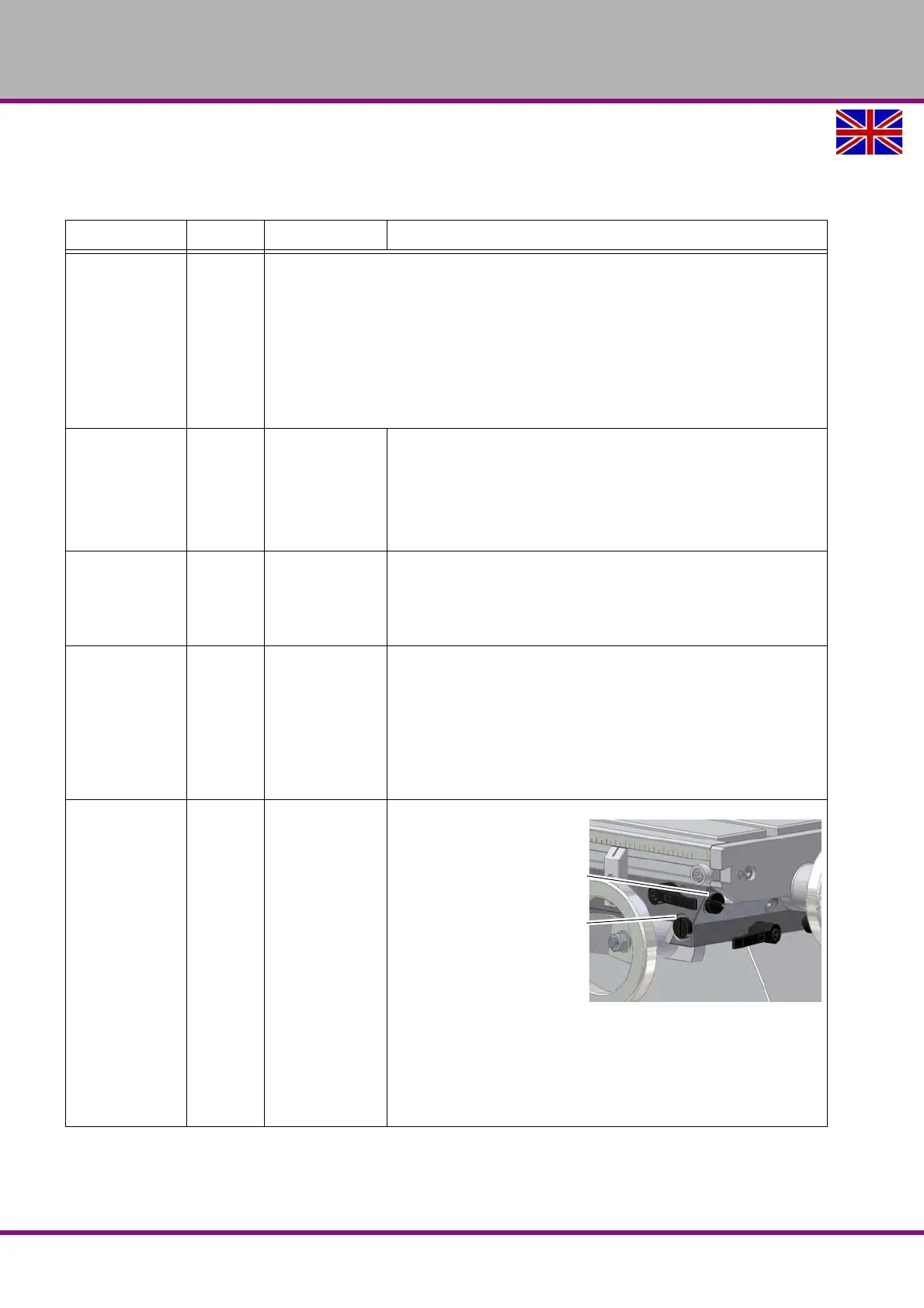

As required

V-ledges

Readjusting

X and Y axis

Img.6-1: Cross table

Turn the take-up screw of the corresponding V-ledge

clockwise. The taper gib is continued to push in and

reduced by it the gap in the guide way.

Check the settings. The corresponding guideway must be

more easily moveable but ensure a stable guiding.

Cross table

Take-up screw

taper gib X axis

Take-up screw

taper gib Y axis

Loading...

Loading...