Bulletin 100-50-9.1 – Page 17

5.4 SENSORS

The S3C control system uses input from several sensors

to control case discharge air, superheat and defrost. It is

important to follow these instructions to ensure proper

location and mounting technique. All sensors should be

provided by Sporlan to ensure compatibility and proper

operation.

Note: Sensor leads may be extended to 100 ft. (30.5m)

with 18 AWG wires and Scotchlok

TM

UR connectors for

long-term integrity. For extending the pressure trans-

ducer cable it is recommended to use Belden 9493 or

equivalent. For extending temperature sensor cabling

it is recommended to use Belden 9409 or equivalent.

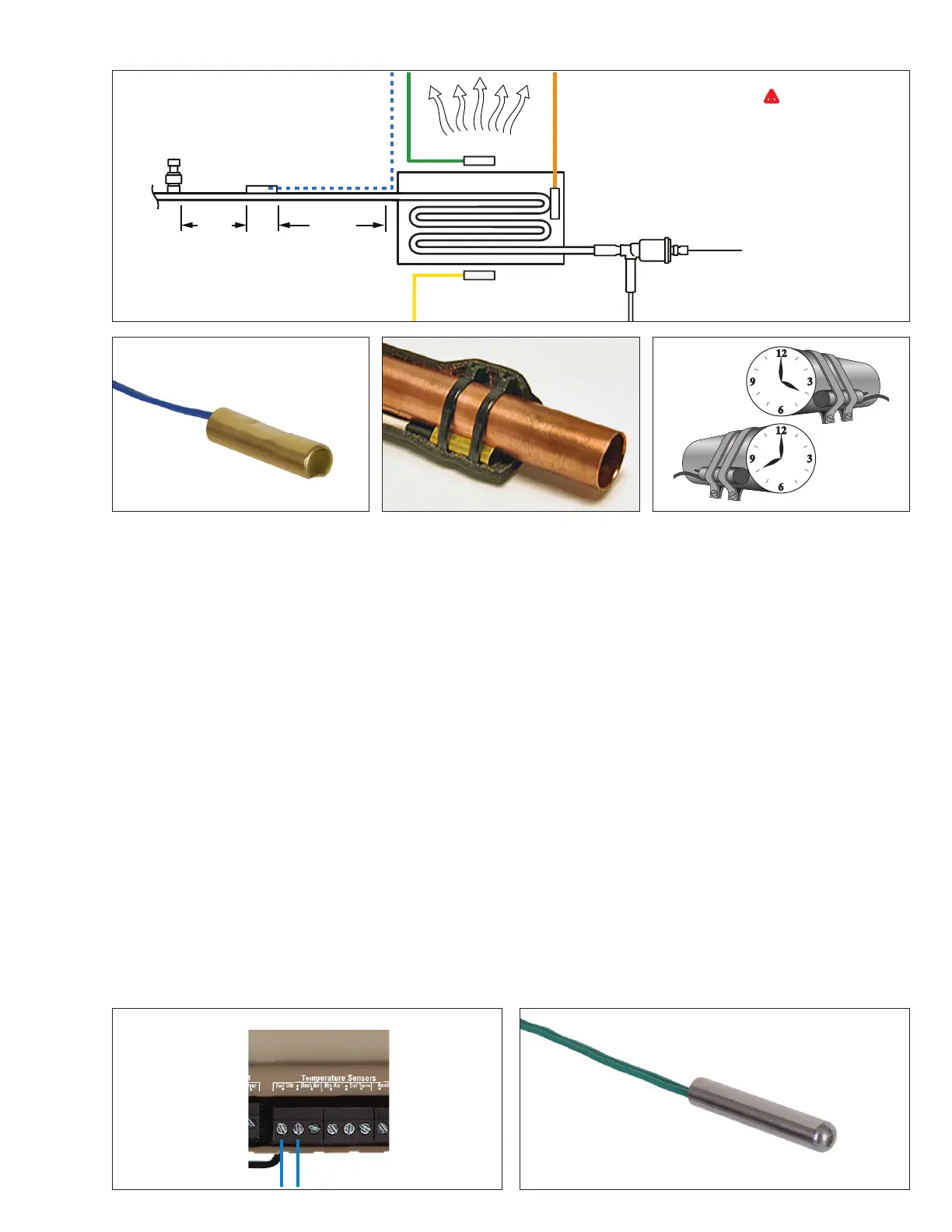

5.4.1 COIL OUTLET TEMPERATURE

5.4.1.1 MOUNTING

The coil outlet temperature sensor is required when using an

EEV and where superheat calculation is needed. The sensor

must be mounted on the suction line after the evaporator as

shown in the figure above. The piping must be horizontal

and free draining. Position the sensor at the 4 or 8 o’clock

position on the suction line. Secure with two heavy duty zip

ties, then insulate.

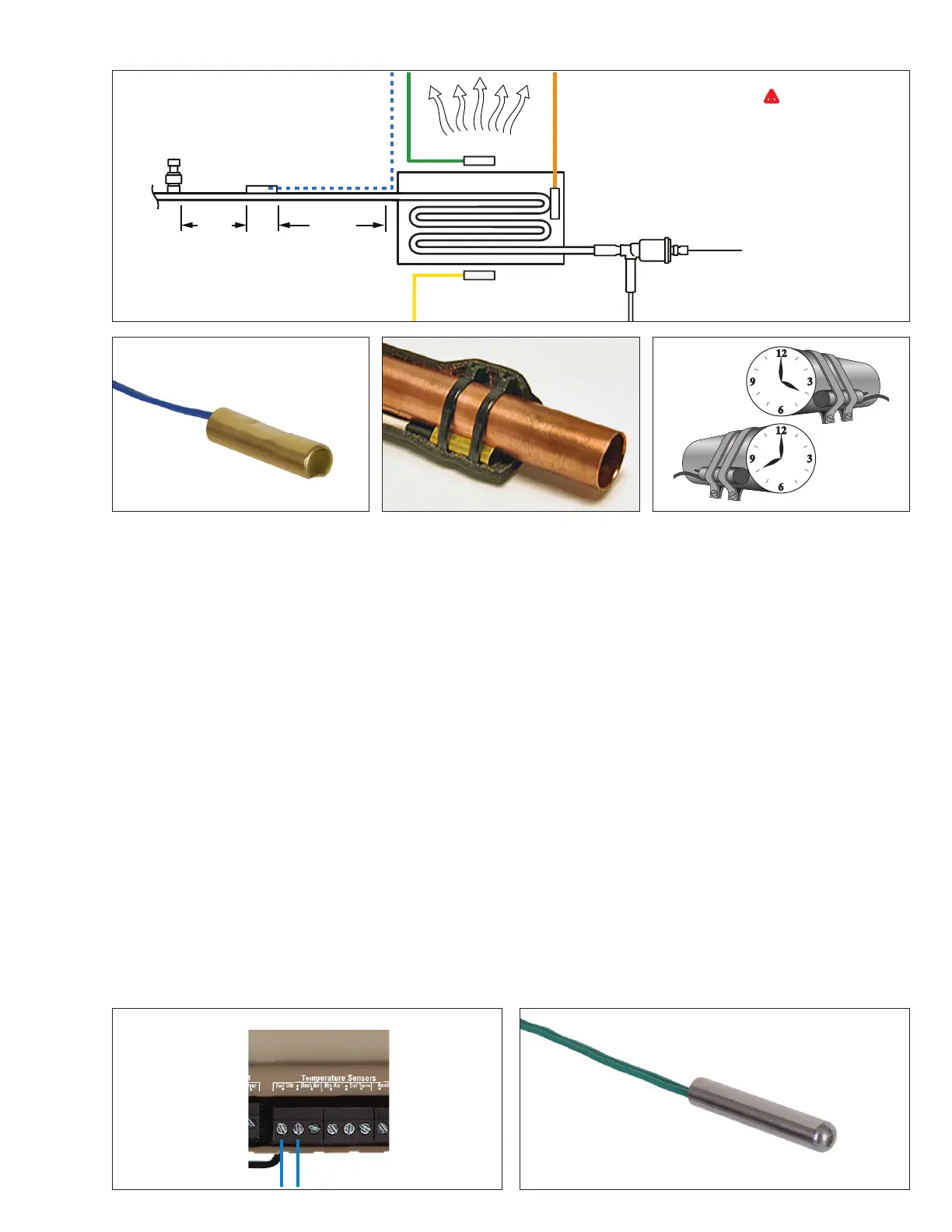

5.4.1.2 WIRING

With controller unpowered, carefully route the blue coil

outlet sensor leads to the controller. Take caution to route

the leads away from sharp edges, fans and defrost heaters.

Ensure the terminal screws on the controller are backed

all the way out. Insert the leads of the sensor wire into

“Coil Out” location on the controller. Tighten the terminal

screws to 3-5 in.-lb. Carefully tug the leads to ensure they

are secure. See the figure below. Note: Leads are not

polarized and may be installed in either location. One

lead of the coil out sensor will share the terminal with

the discharge air sensor.

5.4.2 DISCHARGE AIR TEMPERATURE

5.4.2.1 MOUNTING

The discharge air temperature sensor is required for case

temperature control. The sensor must be mounted inside of

the refrigerated display case. Typical location is the middle

of the case, inside top. The sensor should be mounted in

the discharge air stream, away from large thermal masses

such as mounting brackets and or case struts. Secure with

two heavy duty zip ties. Note: The controller may be

configured to use the discharge air sensor or return

air sensor as the control point.

Coil Outlet

Sensor

Pressure

Transducer

EEV

10”-14”

minimize

1”- 2”

ideal

Evaporator

Discharge Air Sensor

Defrost

Termination Sensor

Return Air Sensor

WARNING: Route

and secure cables away

from hot surfaces, high

voltage lines and moving

components.

Loading...

Loading...