Installer Manual Magnum 742-762 - Maintenance

Ref. MKT-IM-012 / C - 25.10.2019 71 / 106

9.3. 298 CV / IT: General system inspection

Mandatory

Has to be done once a year at minimum.

9.3.1. Water quality

1. Raw water total hardness.

2. Treated water hardness.

9.3.2. Mechanical Checks

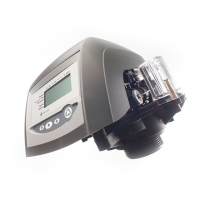

1. Inspect general condition of valve and associated ancillaries and check for any leaks, ensure

valve connection to piping is made with adequate flexibility as per manufacturer instruction.

Inspection of electrical connections, verify wiring connections and search for evidence of

overloading.

2. Inspection of electrical connections, verify wiring connections and search for evidence of

overloading.

3. Verify settings of electronic timer, verify regeneration frequency, make sure the valve

configuration correspond to the settings.

4. Check water meter, if present, report water meter settings and compare with previous

inspection.

5. Verify total water consumption compared to previous visit.

6. If pressure gauges are installed before and after softening system, verify and record static and

dynamic pressure, reporting pressure drop. Verify that inlet pressure respects valve and

softening system limits. Make sure dynamic pressure always remain above 1.78 bar to ensure

proper Magnum valve function.

7. If pressure gauges are not present, but suitable points exist, install temporary pressure gauge(s)

to perform point 6.

9.3.3. Regeneration test

1. Check condition of brine tank and any associated equipment.

2. Check salt level in brine tank.

3. Initiate regeneration test.

→ Check brine draw during brine draw stage.

→ Check brine tank refill.

→ Check operation of safety brine valve, where fitted.

→ Check for brine draw off levels.

→ Check for resin loss at the drain during regeneration.

→ Where fitted, check for satisfactory operation of solenoid valve(s).

→ If a Non Hard Water Bypass cartridge is fitted, make sure there is no water at outlet during

regeneration.

4. Test and record Total Hardness of outlet water from softener vessel(s).

Loading...

Loading...