lbs (42- 45 kgs), belt tension adjustment is not required. If the tension is not within spe-

cification, continue with the belt tension adjustment.

3.

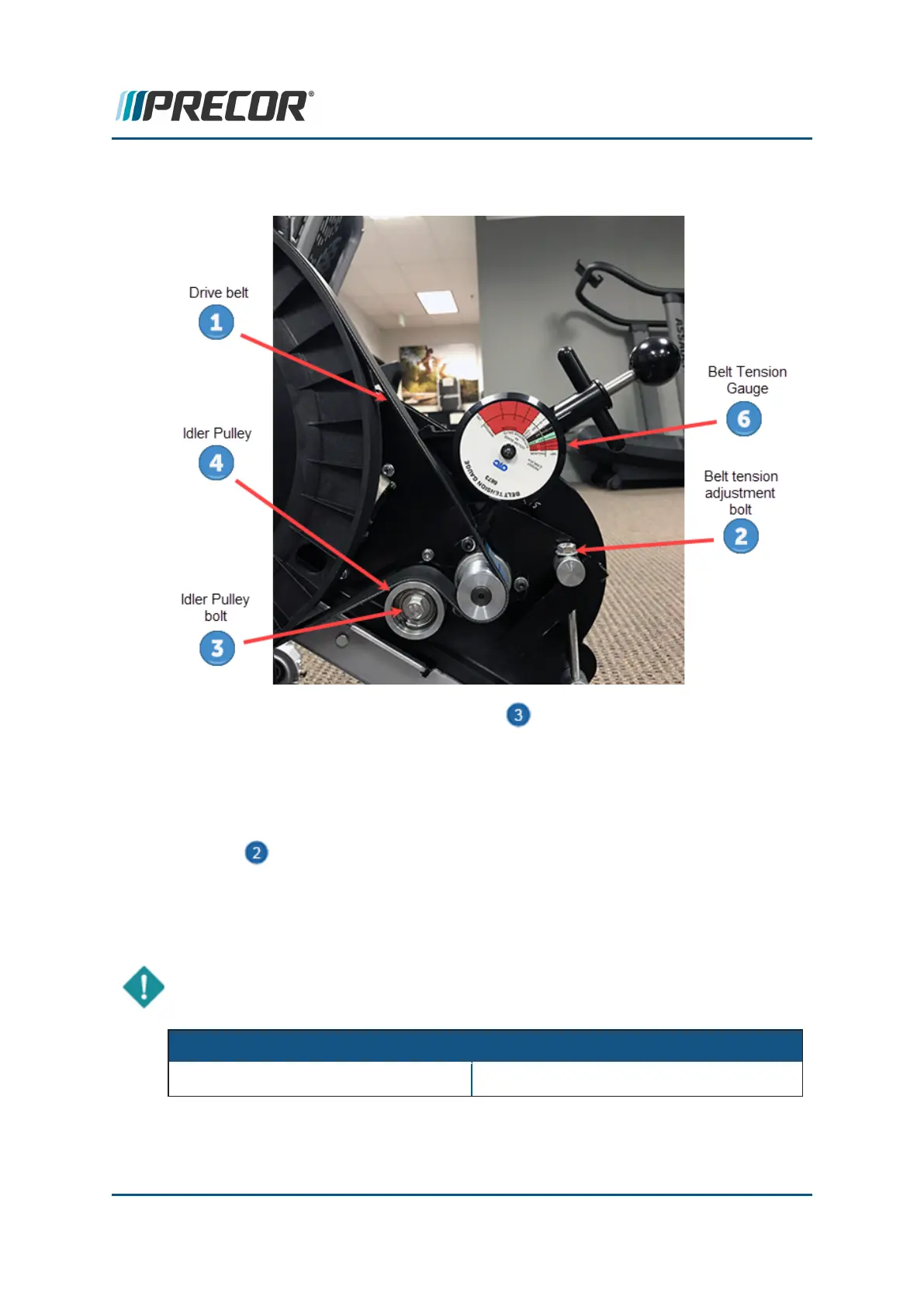

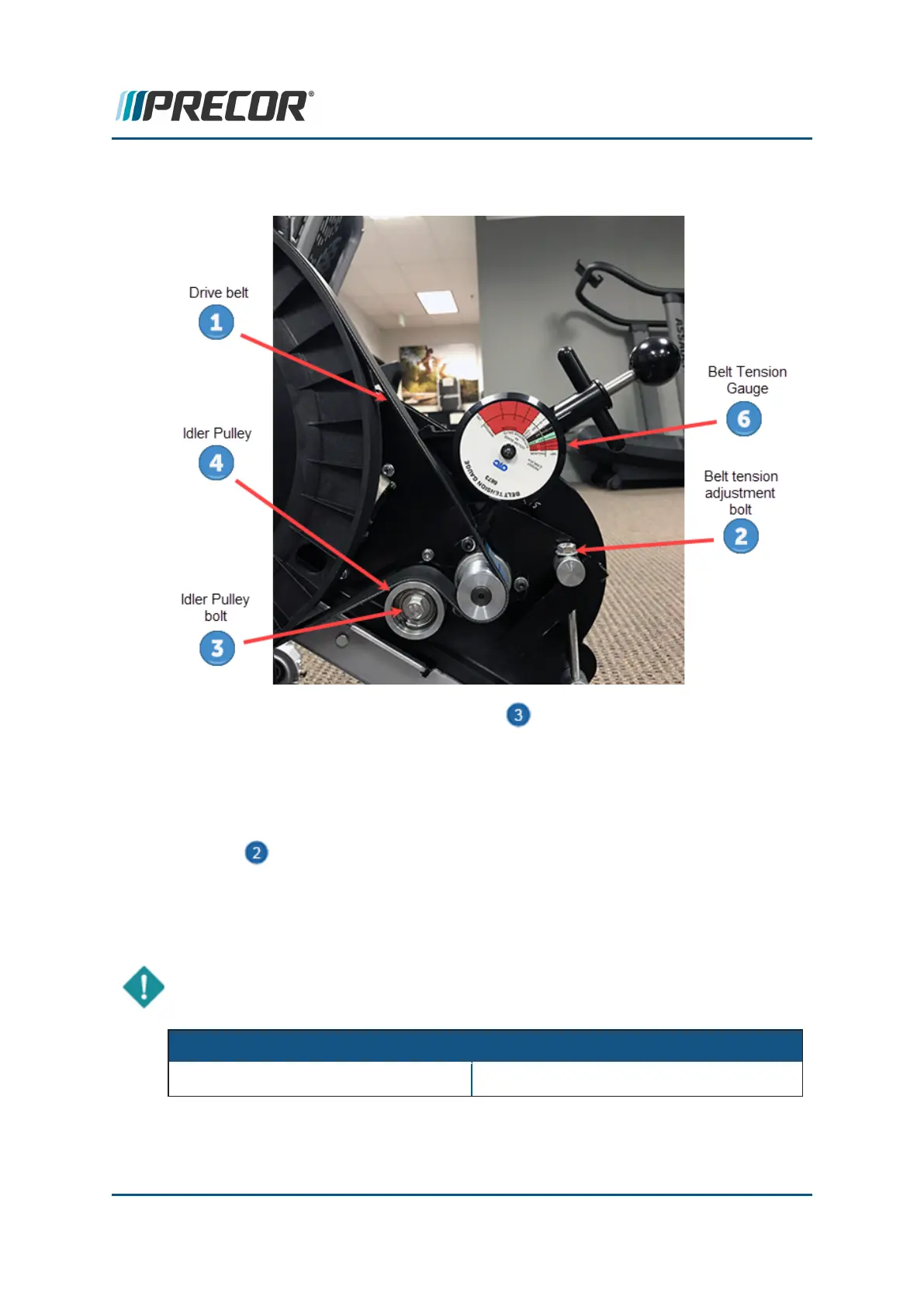

Use a 1/2" socket to loosen the idler pulley bolt .

4. Adjust the drive belt tension to the OEM specification.

a. Use the belt tension gauge to measure the belt tension.

b. Then remove the belt tension gauge.

c. Make small adjustments (1/4 turn increments) to the 1/2" belt tension adjustment

bolt to either increase or decrease the tension as needed.

d. Use the Crank to move and seat the belt to the new tension adjustment.

e. Install the belt tension gauge and remeasure the belt tension.

f. Repeat steps until the belt tension is within specification.

IMPORTANT: The belt tension gauge must be removed while making tension adjust-

ments or the measurement will be invalid.

System Component Specification

Single Stage Belt Drive Tension 93-100 lbs (42- 45 kgs)

Contact Precor Customer Support at support@precor.com or 800.786.8404 with

any questions.

Page 49

5 Adjustment/Calibration Procedures

Single Stage Drive Belt Tension Adjustment

Loading...

Loading...