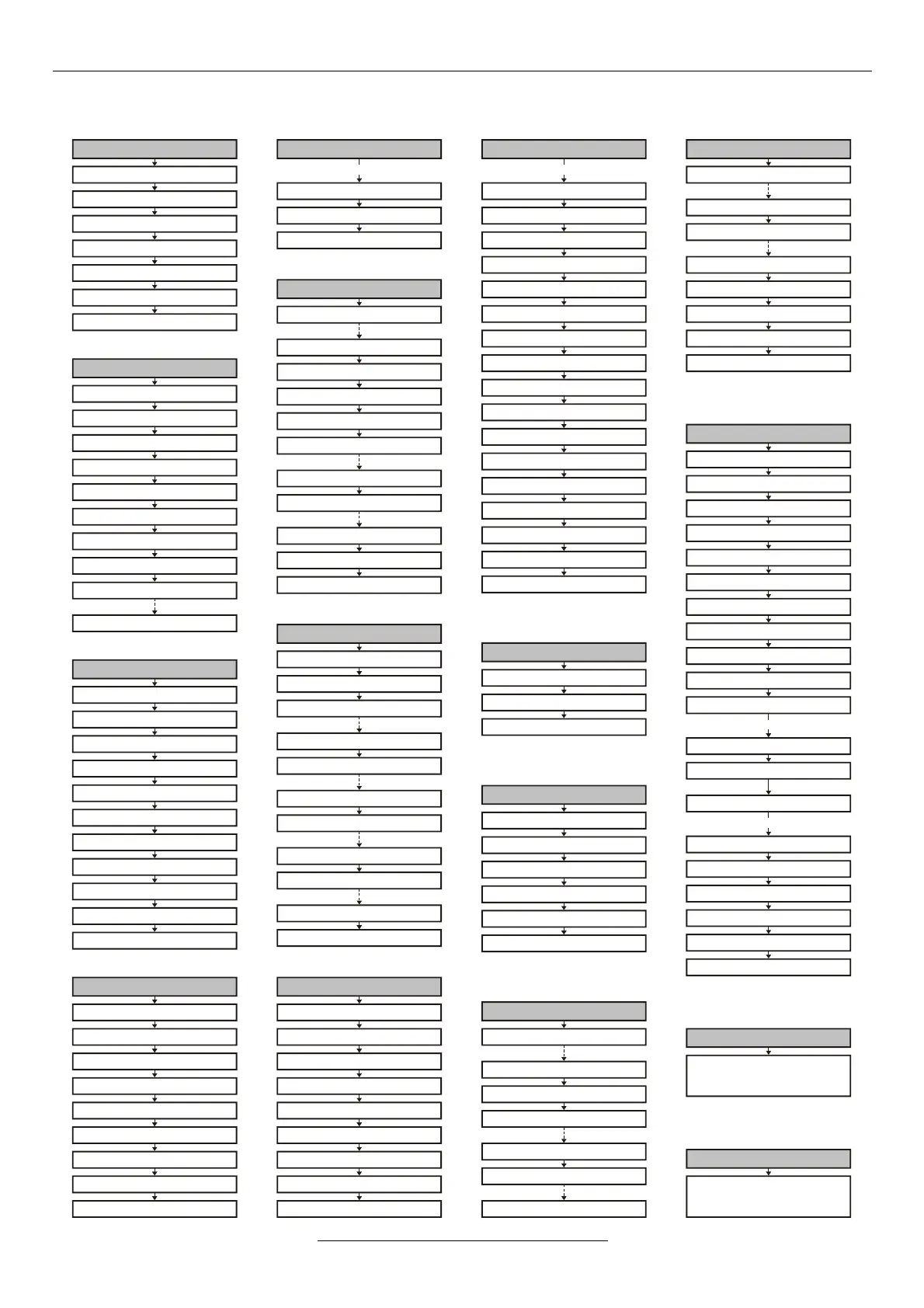

1 - Operation mode

1-1 control ref. signal

1-2 regulation ref. signal

1-3 selection

1-5 control

1-6 regulation

1-7 feedback

1-8 modification

1-10 PID settings

1-11 PID 1 data

1-14 PID 4 data

2-10 fly snips

2-11 flying start

2 - Starts

2-1 rise time

2-2 acceleration

2-3 multistep acceleration

2-4 S curve

2-5 start disable

2-6 direction change disable

2-7 restart

2-8 start type

2-9 brake release

3 - Stops

3-1 fall time

3-2 deceleration

3-3 multistep deceleration

3-5 stop type

3-6 normal brake

3-7 free time

3-8 DC brake

3-9 resistor brake

3-10 Udc hold

4 - Inputs

4-1 analogue input 1.

4-4 analogue input 4.

4-8 logical control source

4-9 logical parameters

4-10 fix start

4-11 digital input 1.

4-21 virtual input 1.

4-18 digital input 8.

4-26 virtual input 6.

4-30 slave data

4-31 IRE data

5 - Outputs

5-1 analogue output 1.

5-2 analogue output 2.

5-11 digital output 1.

5-16 timing 1.

5-21 comparator 1.

5-26 period 1.

5-13 digital output 3.

5-18 timing 3.

5-23 comparator 3.

5-28 period 3.

5-29 PID extension

10 - Displays

10-1 row 1.

10-4 row 4.

10-7 productivity 1.

10-10 4.productivity

10-12 big characters

10-11 user define units

10-13 consumption meter clear

10-14 active menu

11 - System

11-1 parameters

11-4 macro

11-5 remote control

11-6 modulation

11-7 slip-compensation

11-8 output

11-9 language

11-10 CAN bus

11-12 terminal function

11-13 automatic error ackn.

11-14 save event

11-18 manufacturing number

11-19 software version

11-20 date

11-21 currents

11-22 voltages

11-23 special data

11-24 clear log

11-25 password

11-27 menus with password

READ ONLY

PASSWORD PROTECTED

0 - Quick menu

0-1 control Tup

0-2 control Tdown

0-3 motor In

0-4 f maximum

0-5 f minimum

0-6 U boost

0-7 active menu

12 - Events

The event log can store

256 events along with

the belonging point of times.

13 - Errors

The error log can store

256 errors along with

the belonging point of times.

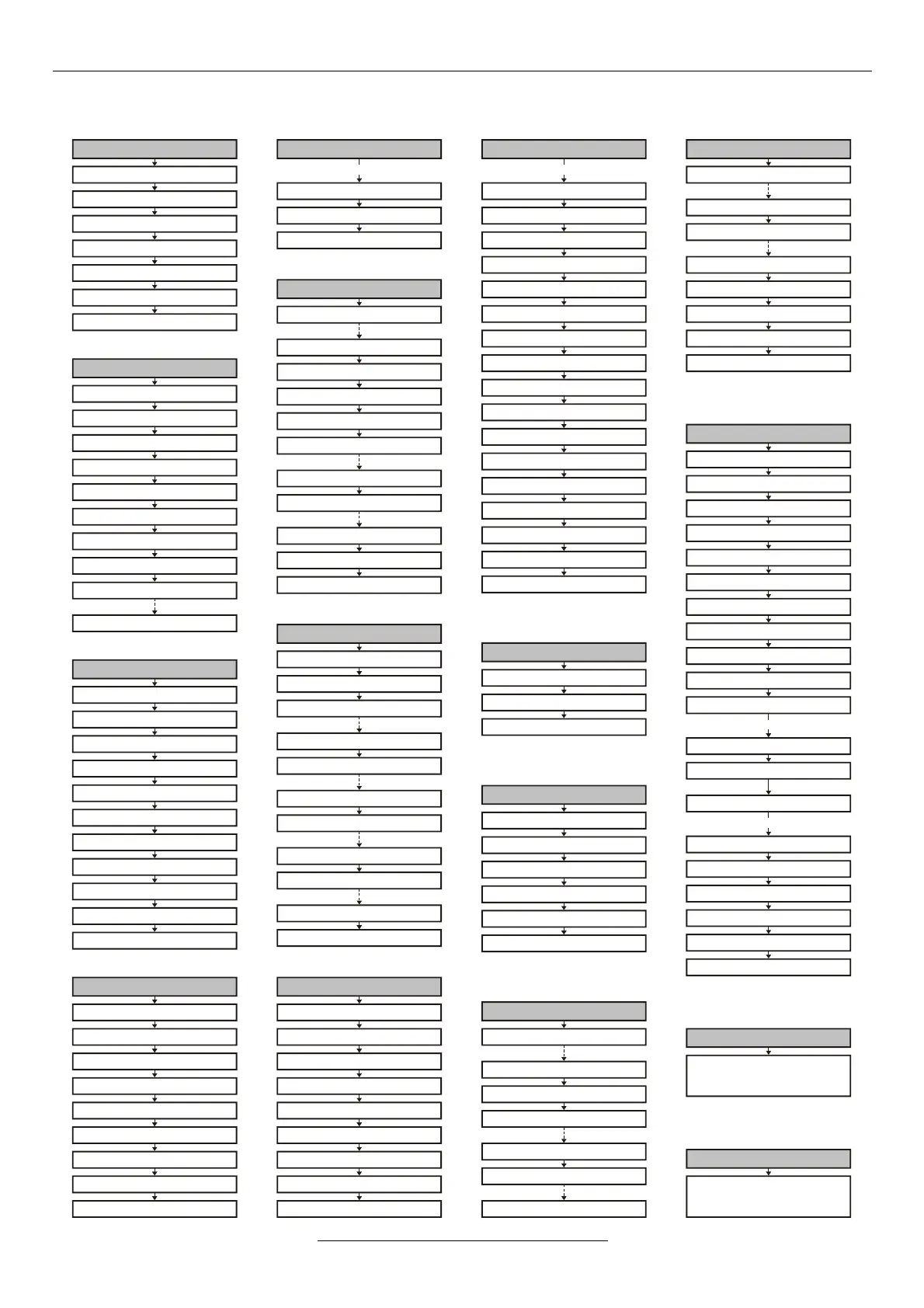

6 - Motor

6-1 nominal power

6-2 nominal voltage

6-3 nominal frequency

6-4 nominal current

6-5 nominal rotation speed

6-6 cooling type

6-7 limit

6-9 torque limit

6-10 test

6 - Motor

6-12 n maximum

6-11 R stator meas.

6-13 R stator

6-14 L stator

6-15 magnetizing current

6-16 linearity of the magn. current

6-17 exponent of the magn.current

6-18 R rotor correction

6-19 nominal start time

6-20 I regulator

6-22 n regulator

6-23 field weakening

6-24 sensorless

6-25 blocking

6-26 R rotor adaptation

6-27 sync. offset

6-28 type

continued

7 - U/f ratio

7-1 characteristic types

7-2 U/f modification

7-3 user characteristic

8 - Frequencies

8-1 f maximum

8-2 f minimum

8-3 frequency inhibit limit

8-4 jog normal

8-5 jog inverse

8-6 inhibited bands

9 - Programs

9-1 counter 1.

9-3 3.counter

9-10 program activation

9-11 program 1.

9-25 program 15.

9-26 sequence 1.

9-28 3.sequence

3-11 brake operation

3-12 Udc filter

3-13 emergency fall time

3 - Stops

continued

Loading...

Loading...