At setting the PID parameters be very careful,

because the quality of the regulation depends on

this setting!

Prior to setting the parameters, clarify if the job

needs proportional regulation, PI regulation or really

a PID regulation?

The absolute limitation of the output frequency (f) is

built into the regulator therefore at reaching the limit

the I element will not be integrated off!

The limitation of the acceleration and deceleration

slopes of the output frequency (f) is independent of

the regulator. Setting wrong parameters (e.g. too

large deceleration time and short integration time)

may cause the regulator to be integrated off thus the

system to swing over.

Some hints

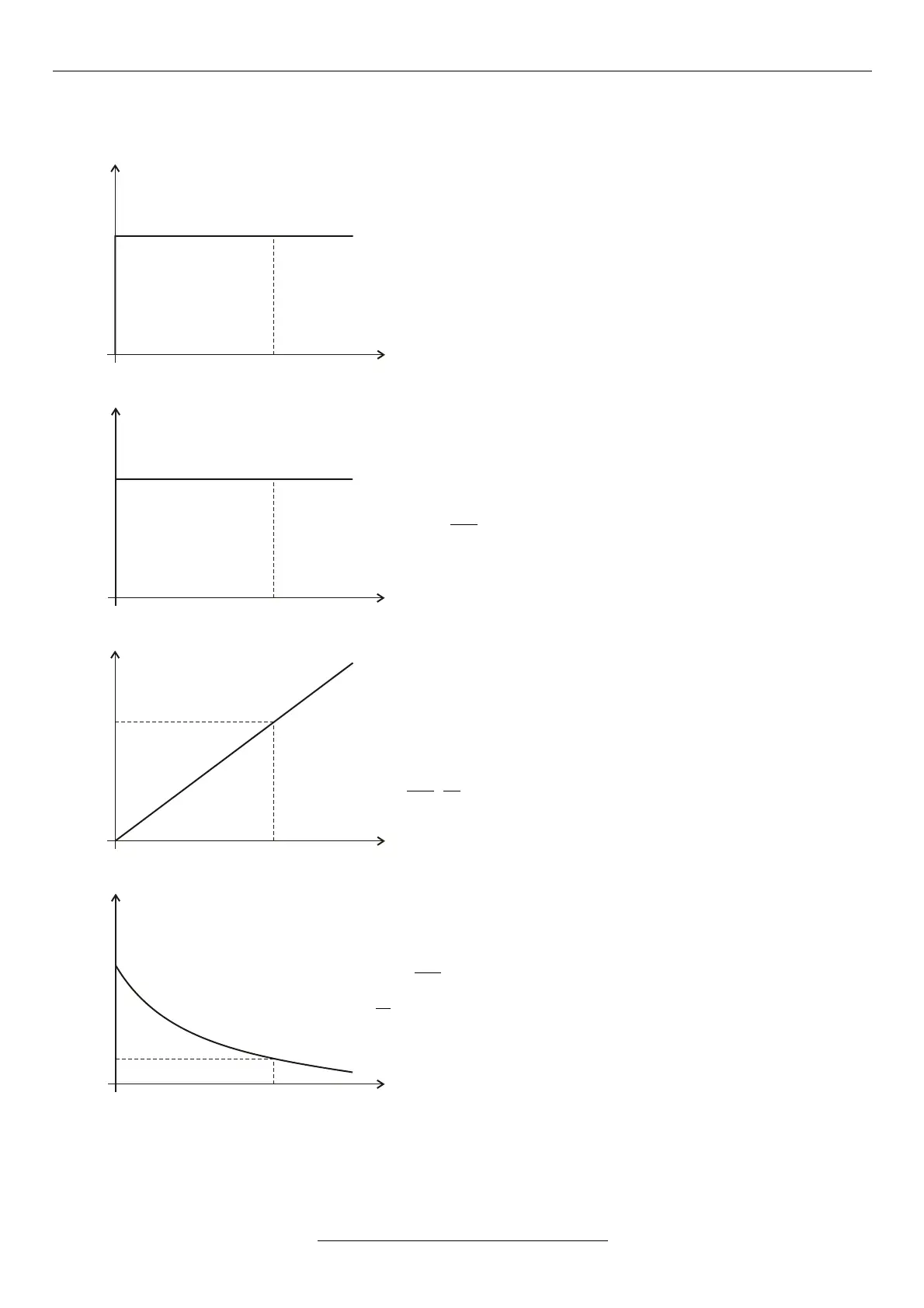

P (proportional): For simple regulations (e g. fluid

level regulation) it is practical to use proportional

regulation.

Thus, the set-in process is the fastest and there is

no tendency to swinging.

The regulation works with the minimum error (due

to the regulation being proportional to the error

signal) but this is not essential at these kinds of

applications. (Ti=N, Ad=0)

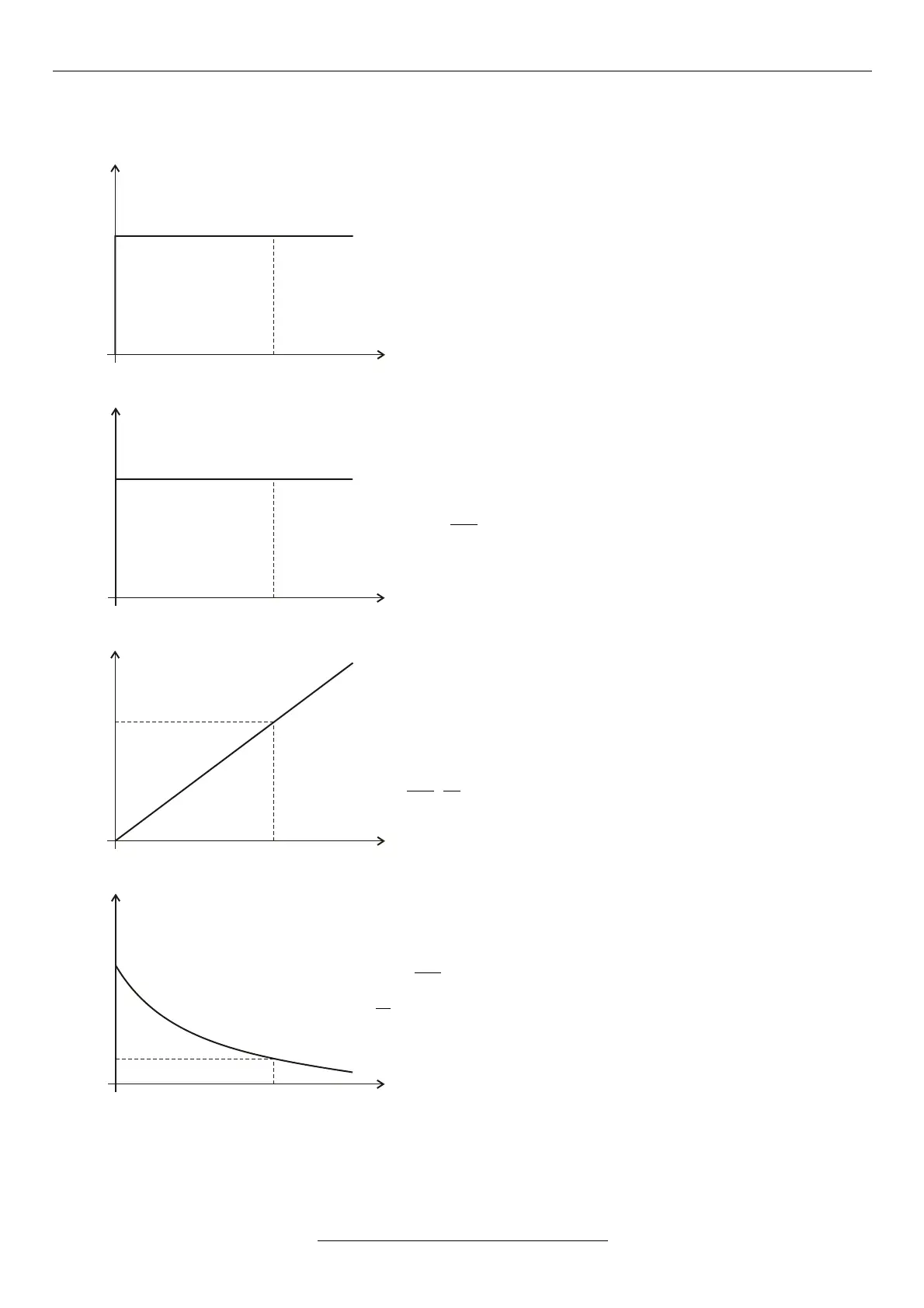

The PI regulation can be used at regulation tasks of

relatively high time constant.

(e g. pressure regulation with pumps or temperature

regulation with blowers etc.) (Ad=0)

PID regulation has to be used for fast regulations.

(e g. regulation of the rotation speed)

At adjusting Ad and Td special care has to be taken

to avoid swingings but maintain the speed of the

regulation!

Loading...

Loading...