H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 77 -

Error acknowledgement

The errors can be acknowledged in the following ways:

• switching the frequency converter off and on,

• giving a rising and falling edge to the input programmed for acknowledgement,

• from the terminal, pushing the “Enter” button in the 13 Errors menu, at the last error

After acknowledgement the display image appears.

The „Erased” display gives the date of erasing the error log

If the operation voltage is low, writing the error log is disabled. In this case, the equipment cannot receive start command

either!

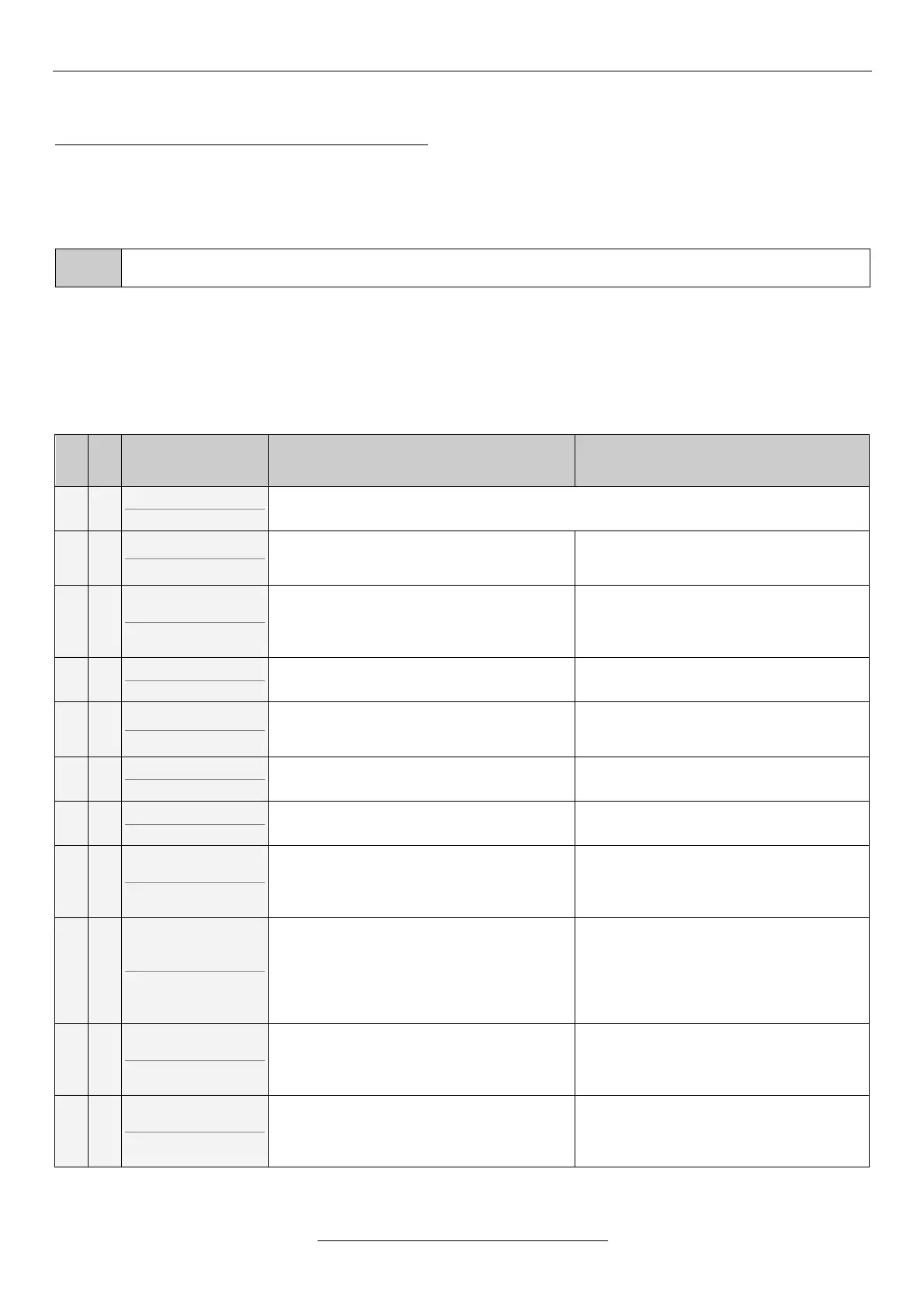

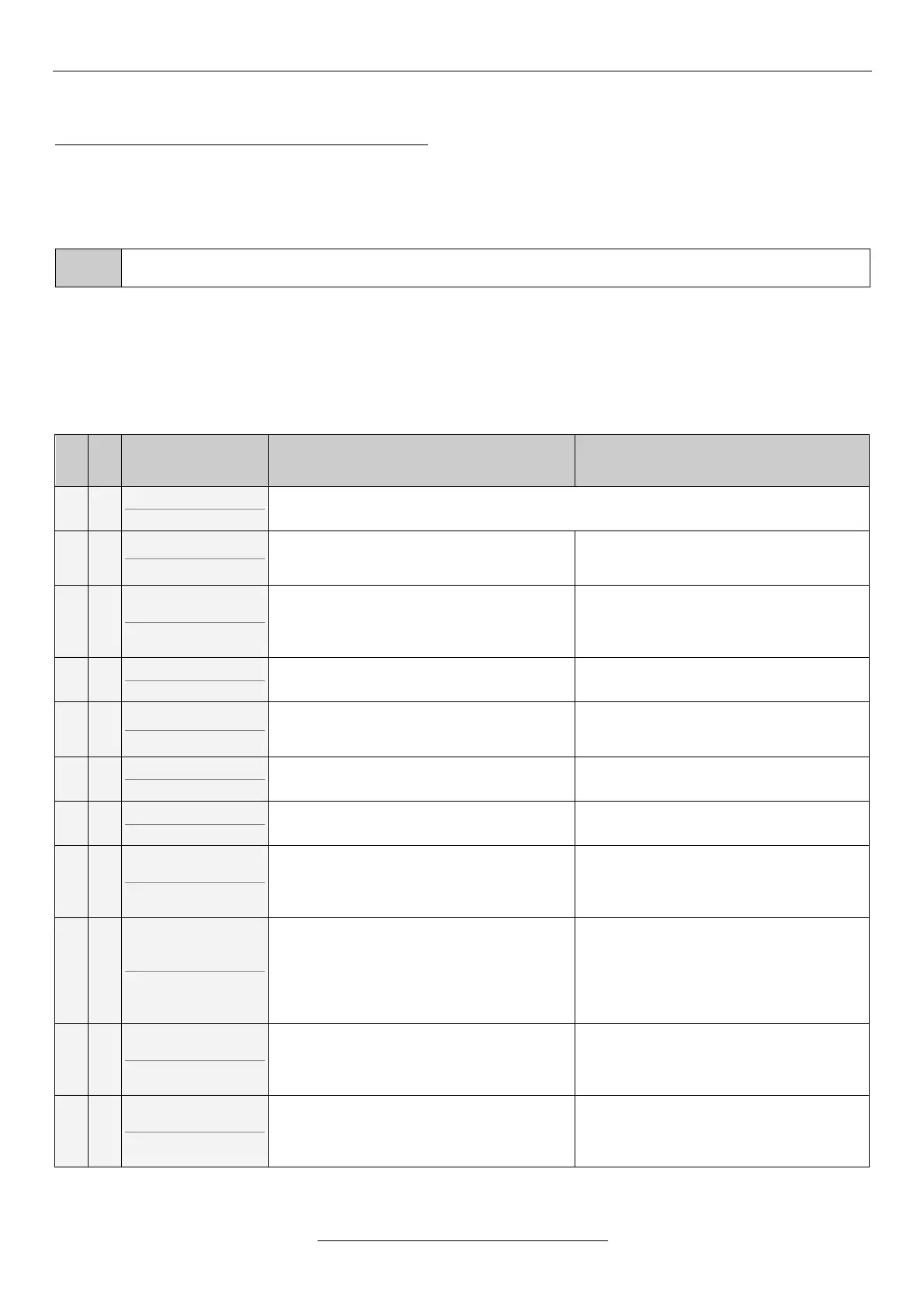

List of errors

On 16 character display the upper (e.g. External error 2.), on 8 character display the lower (in shortened form, e.g.

Extern. 2) „Displayed text” appears at the actual error.

Short description of the error

No more error in the log (in base state this will be shown only)

External error 1-8.

(Extern.1-8)

Error signal produced with activating the

Digital IN1-8. (e.g. signal from the thermal

switch on the motor, field inhibition etc.)

Checking the device causing the external

error.

Virt. error 1-6.

(Virt. 1-6)

Error signal produced with activating the

Virtual IN1 – IN6. (e.g. inhibition through a

comparator assigned to the value of an

analogue signal).

Checking the source of the virtual input,

e.g. the input signal of the comparator or

its settings

Term. trip out

(Term.tri)

The terminal regulation is not enabled, but

a stop command was given out from it!

Enabling the terminal regulation, if

necessary

An. ref. high!

(An.ref.h)

The frequency converter senses the 10 V

reference voltage higher.

Check that the SA1 and SA3 connectors

are not receiving a voltage from the

outside.

The frequency converter senses the 10 V

reference voltage lower.

Check if the reference voltage is shorted

or excessively loaded.

Term.par.Chksum

(Term.par)

CHKSUM error in the parameter set stored

in the terminal thus it cannot be loaded.

Loading another proper parameter set or

repeated setting of the equipment.

Blocking error

(Blocking)

Based on the incremental rotation speed

transmitter, the frequency inverter senses

that the motor does not rotate. It is

mechanically stuck or the transducer is faulty.

Motor overtempt.

(Mot.temp)

The motor temperature is too high

according to the thermal model.

• Setting forced cooling in menu item

6-6 or reducing the load.

• Raising the temperature limit in menu

item 6-7-3.

• Checking the setting of the motor

parameters.

No motor connected to the motor clamps or

the motor power is too low.

(observation: from 4Hz to 400Hz, if Imotor

< 6% of In)

The error observation can be set in menu

item 11-8-1.

Motor test error

(Motor te)

The parameters calculated by the motor

test are outside the adjustable range.

Check:

• Setting of the motor param. (menu 6)

• Cabling and connections of the motor

(star, delta)

* The external errors and the virtual errors with even number can be acknowledged also with automatic error

acknowledgement.

Loading...

Loading...