H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 81 -

Regulation on pressure using a 4 to 20 mA pressure remote transmitter

Let the pressure remote transmitter be of measuring range of 0 to 10 bar, the pressure to be kept should be adjustable

between 4 and 8 bar.

The pressure to be kept should be 6 bar, reaching the pressure should last at least 30 seconds after start

(for taking care of the supplying unit e g. the well)

The pump starts to convey from 20 Hz on, cannot be driven above 50 Hz, it cannot be operated more than 1 minute at

the minimum frequency (it must be stopped), but in the case of 0.5 bar pressure drop it must be started again.

The reference signal of the regulation has to be given from the terminal

Remark: according to the remote transmitter data, 10 bar corresponds to 100%

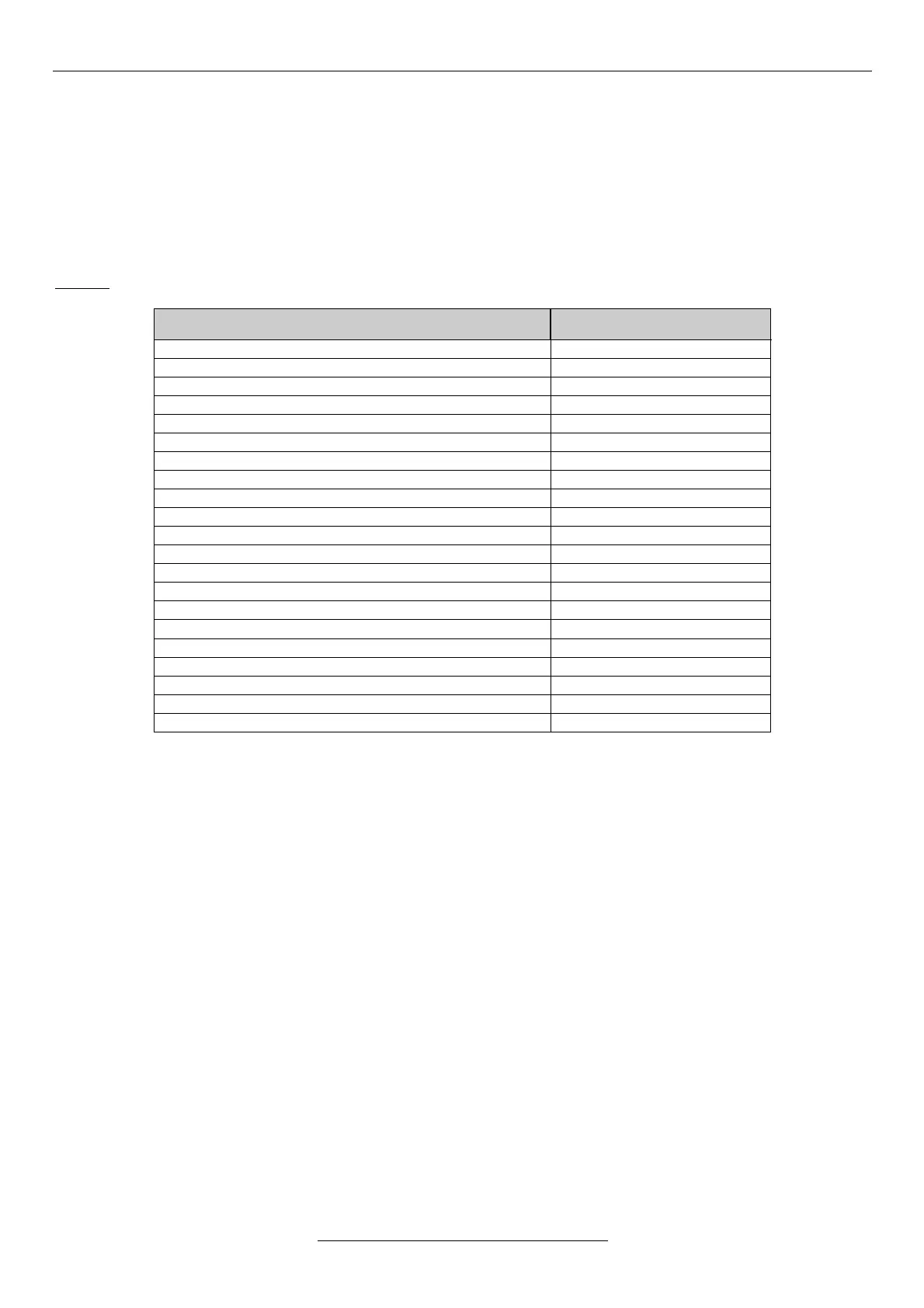

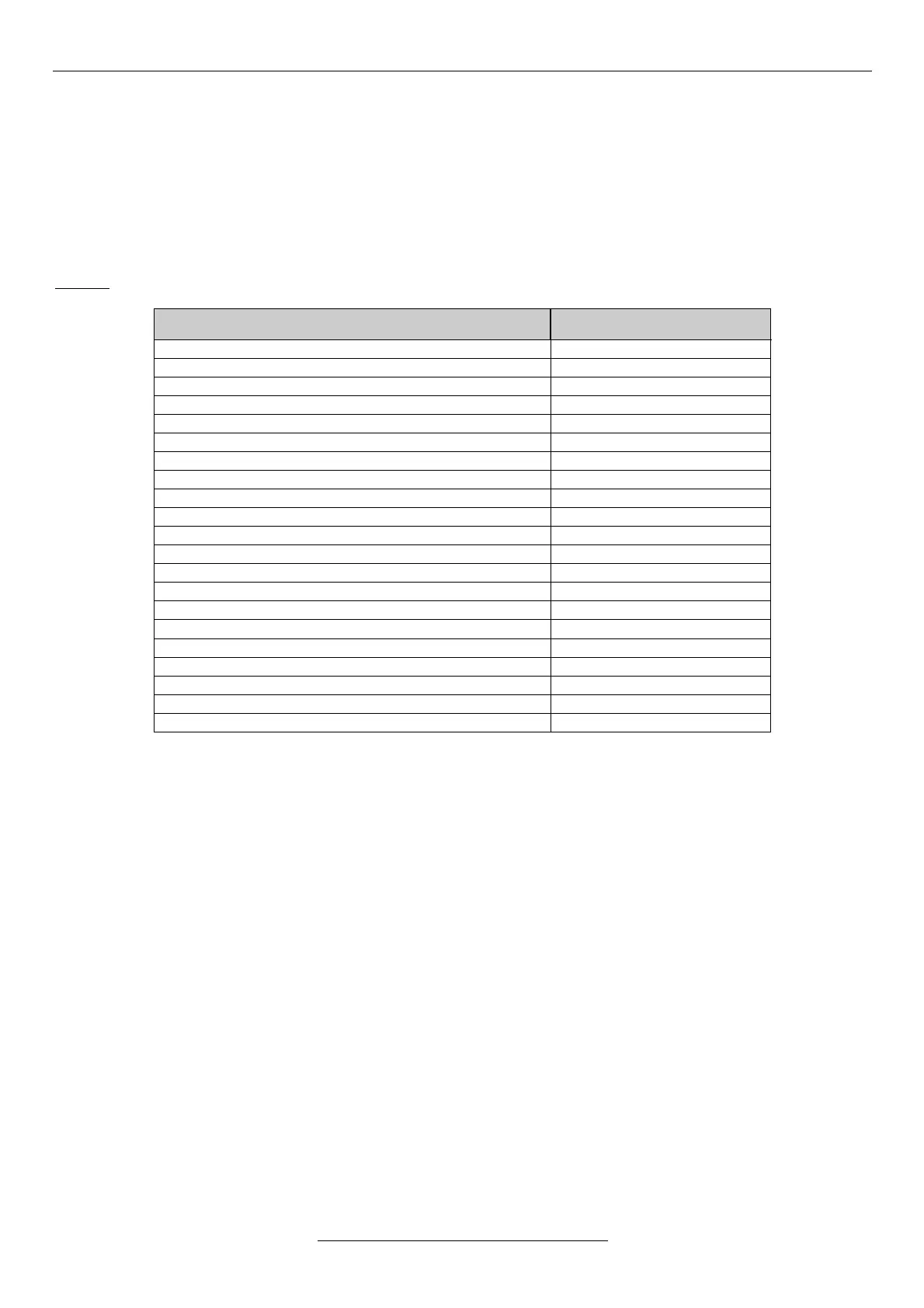

source of the regulation ref. signal

regulation reference signal maximum

regulation reference signal minimum

regulation reference signal acceleration

regulation start / stop time limitation

regulation start error signal

regulation start / stop hysteresis

source of the feedback signal

analogue input 1. current upper level

analogue input 1. current lower level

regulation reference signal

PID 1 Ap (proportional gain)

PID 1 Ti (integration time)

PID 1 Ad (diff. element overdriving factor)

At simple pressure regulation the most suitable regulation type is "PI" or "I".

The value of Ad is 0.00. By this, the effect of the differentiating elements (Ad, Td ) is switched off.

Setting of the PID parameters depends on the system, they always have to be adjusted to the actual requirements

The start/stop commands can be given out from the terminal blocks, the control reference signal modification from the

terminal.

Loading...

Loading...