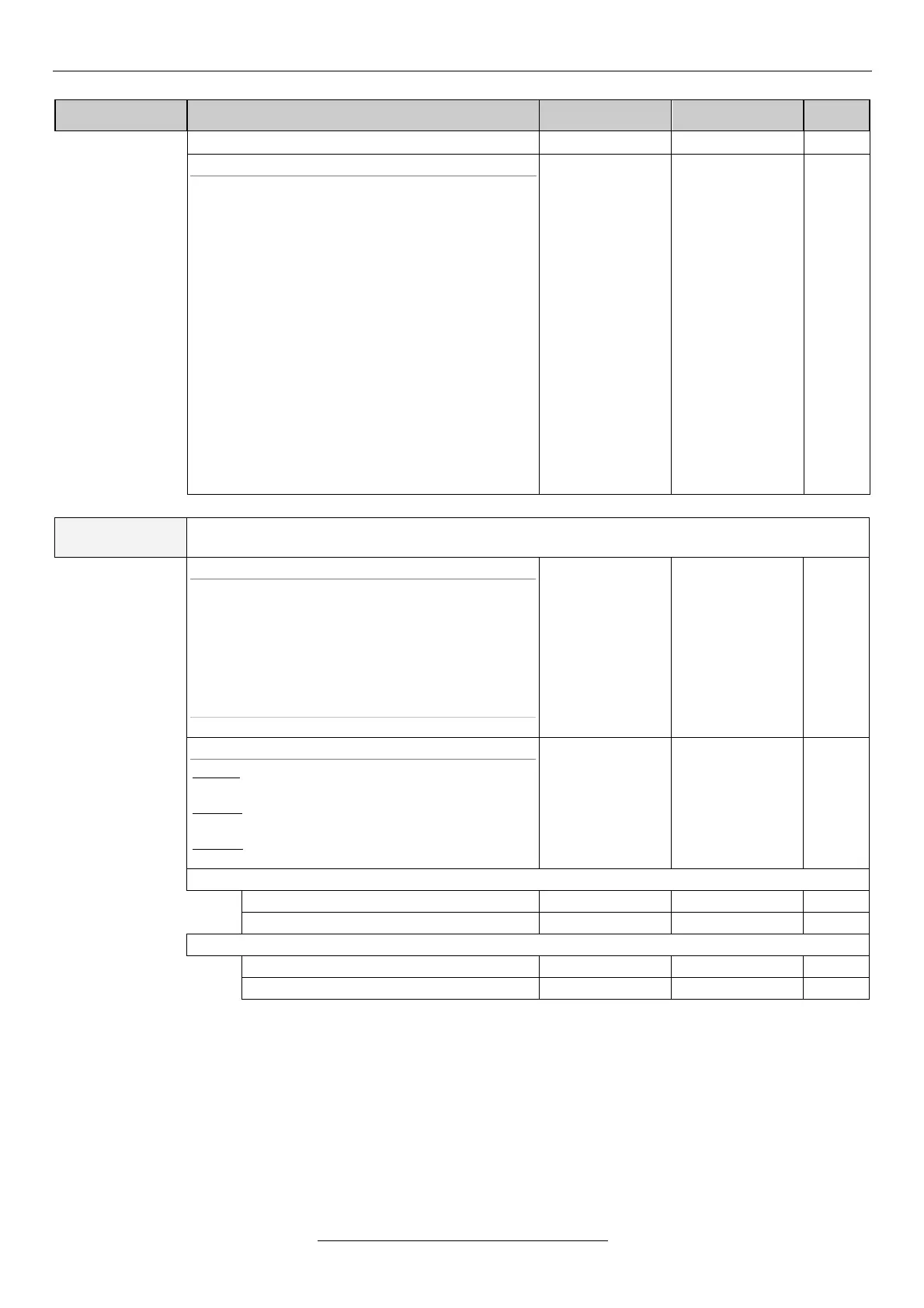

1-5-7 dimension

This serves establishing and displaying the

reference signal corresponding to the

manufacturing process.

The correspondence needs to be related to 100

Hz.

If the product is e.g. a bag, its number of pieces

changes linearly with the reference signal, and

with 30 Hz reference signal 6 bags are produced.

Then the ratio is 30 / 6 = 5, that is setting the

correspondence to 100 / 5 = 20 and the dimension

to pieces in menu 1-1, the regulation reference

signal will be displayed in pieces instead of Hz.

Thus, adjusting the number of produced bags is

much easier, because the operator does not need

to recalculate it to frequency reference signal.

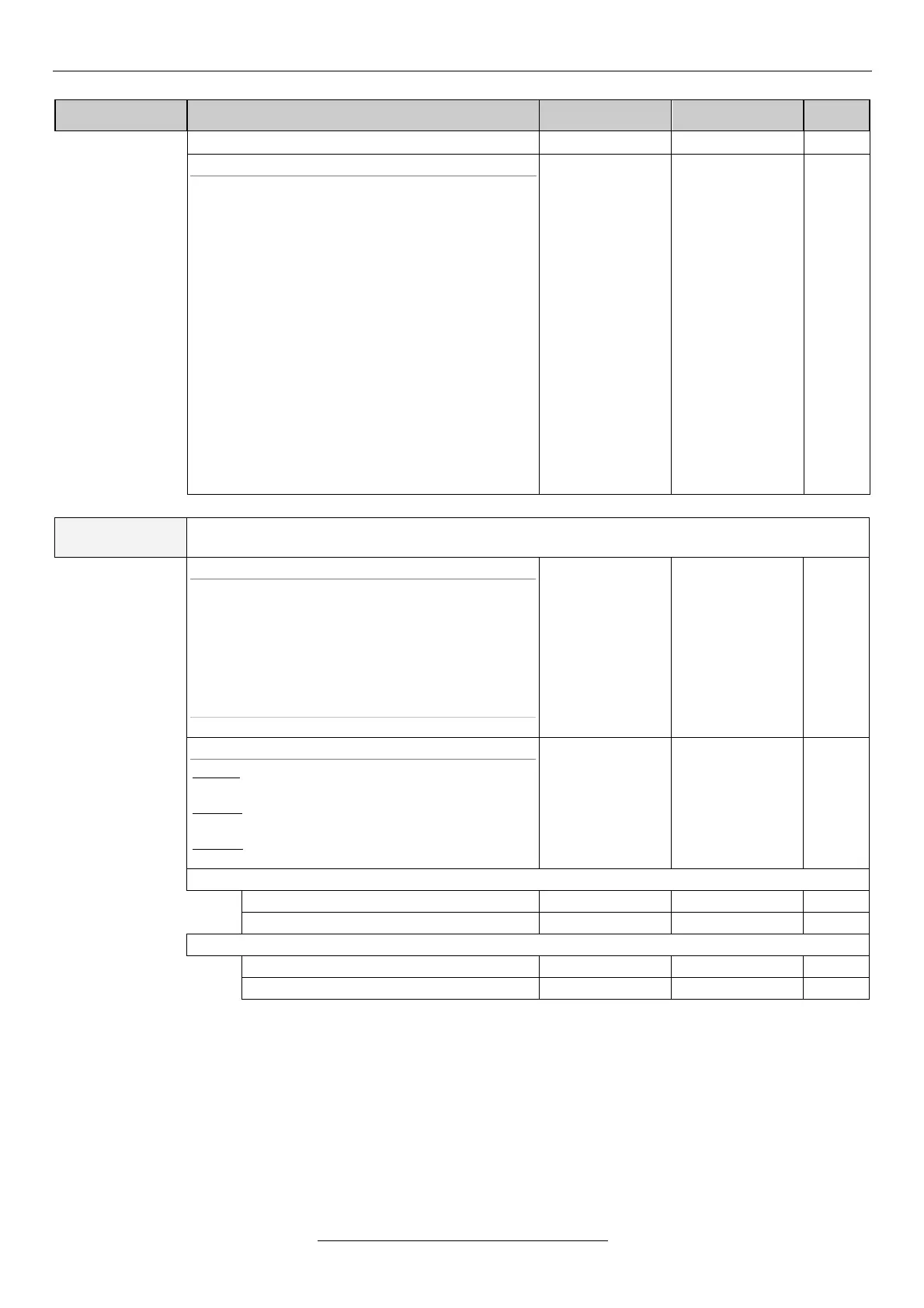

1-6-1 source of the regulation ref. signal

Selects the source of the regulation reference

signal.

(Setting the parameters of the regulation

reference input is made in the 4. Inputs menu!)

* IRE 2 for VLD and VHD types only

1-6-2 type of the regulation

normal: increasing error signal effects increasing

frequency.

inverse: increasing error signal effects decreasing

frequency.

bidirect: normal regulation with changing the

direction of rotation

Loading...

Loading...