H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 79 -

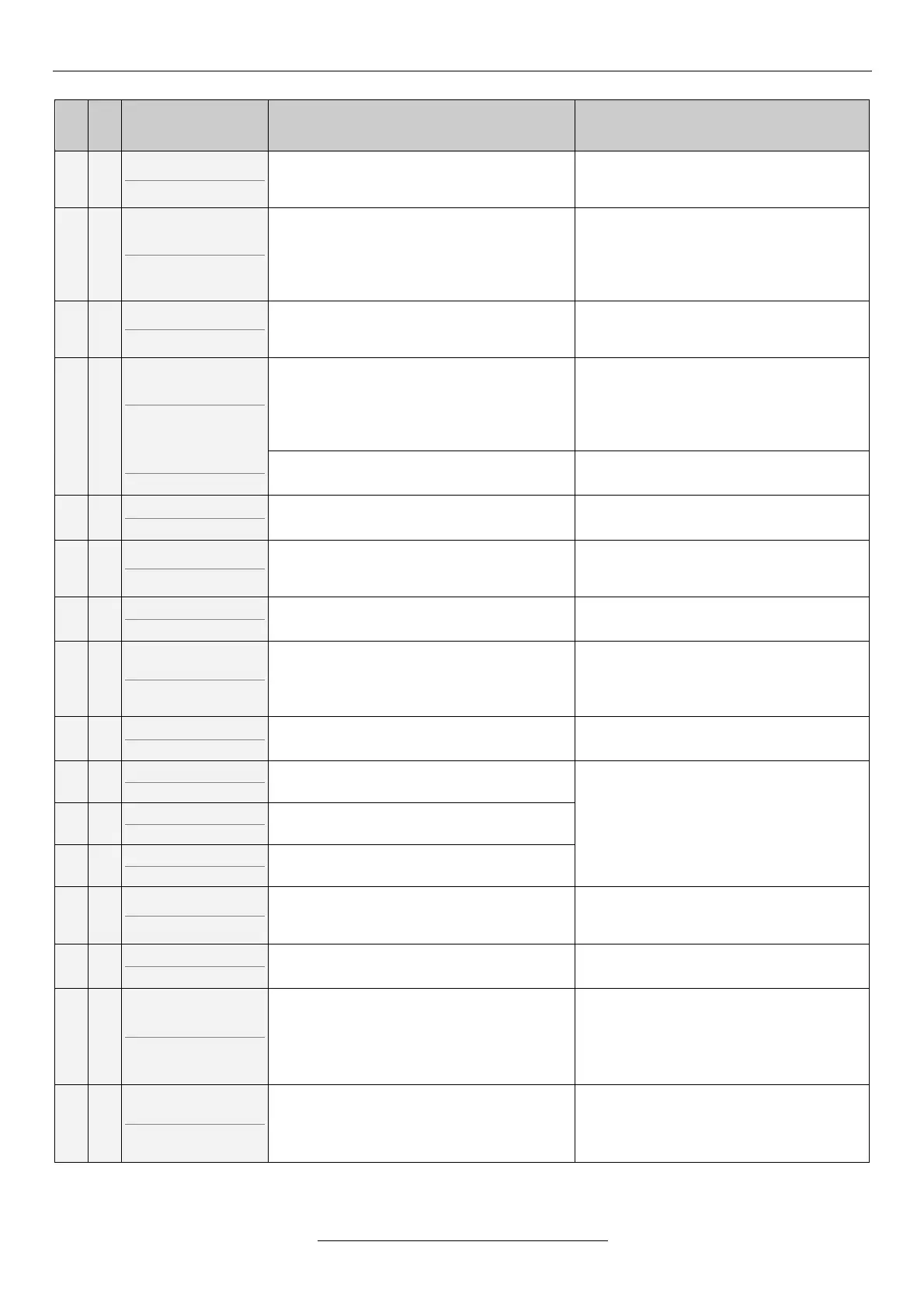

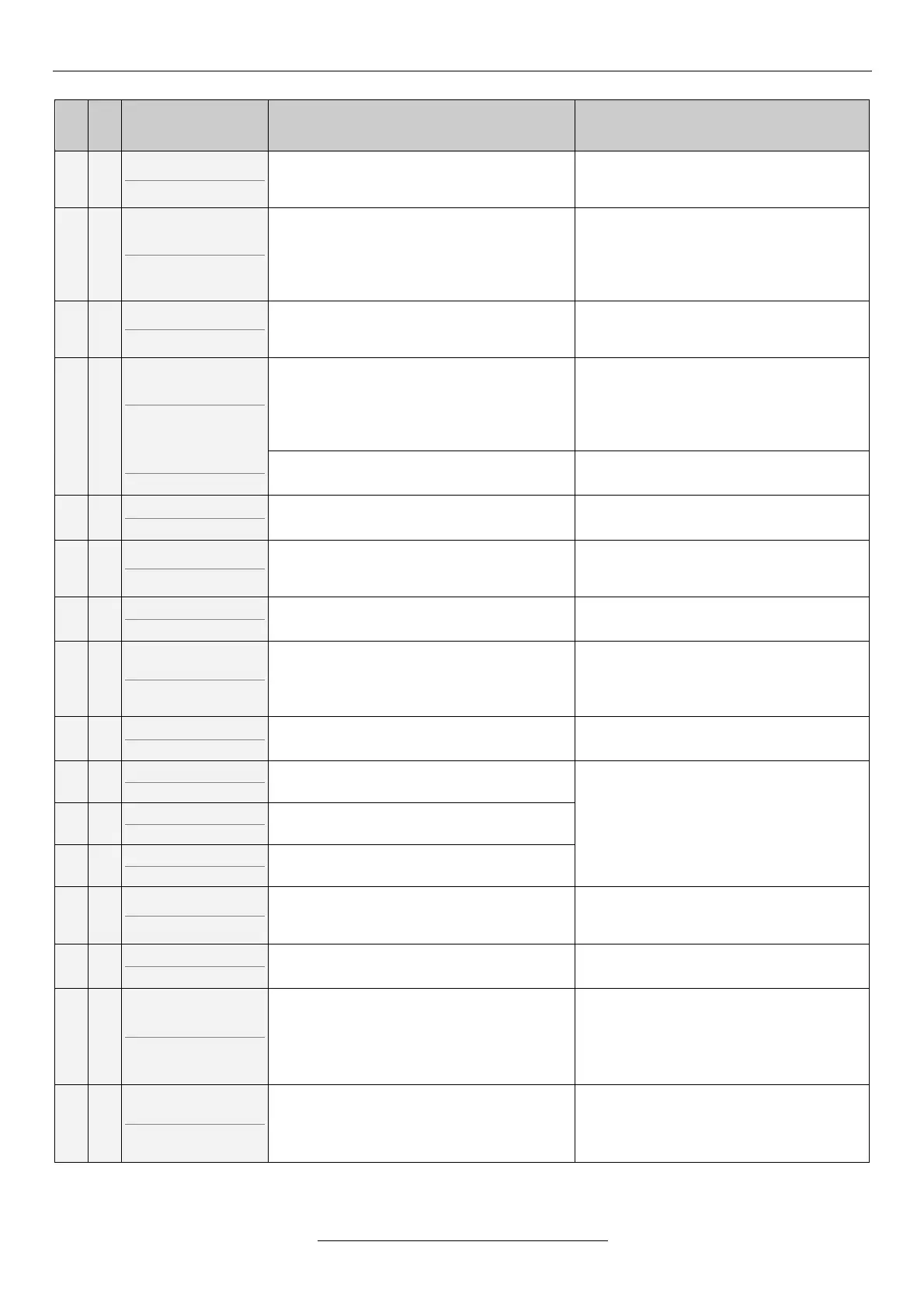

Short description of the error

Par.err.An.IN1-4

(P.An.IN1-4)

Insufficient parameter selection for the

given number of analogue inputs. (The

selected input has more than one function.)

Checking and improving the setting of the

parameter

Parameter error

(Par.err.)

Not coherent parameters have been

selected to the selected mode.

(e.g. flying start with brake loosening, at

master equipment source of reference

signal CAN)

Checking and improving the setting of the

parameter

Not user macro

(Non user)

At macro copying, in 11-4-2 not a user

macro is selected. Copying cannot be

performed.

In menu 11-4-2 selecting user macro 1, or

user macro 2 then copying.

Error in the saved data.

(e.g. not proper value in the parameter

table)

By pressing the exit button, the program

skips to the wrong parameter. The

parameter is offered with the factory value.

In case of several faulty parameters, the

program shows them in line.

EEPROM write er.

(EEPROMwr)

Internal error. The manufacturer is

required to troubleshooting.

Indicates error in the internal

communication (I

2

C). (clock, EEPROM)

Internal error. The manufacturer is

required to troubleshooting.

Interface error1

(Interfac)

No connection with the unit performing the

procession of the analogue and digital

inputs.

Internal error. The manufacturer is

required to troubleshooting.

Interface error2

(Interfac)

Error in processing the analogue inputs or

several digital inputs.

Internal error. The manufacturer is

required to troubleshooting.

Par. CHKSUM err.

(Par.CHKS)

CHKSUM error of the parameter set.

If this error occurred at powering the

equipment, the equipment will continue

operating with the factory settings.

Loading a proper parameter set saved

earlier, or repeated setting of the

equipment.

Turn off CHKSUM

(Turn off)

CHKSUM error of the switch-off buffer.

Internal error. The manufacturer is

required to troubleshooting.

Iu measure error

(Iu measu)

Large offset error of the motor current

measuring in the U phase.

Internal error. The manufacturer is

required to troubleshooting.

Iv measure error

(Iv measu)

Large offset error of the motor current

measuring in the V phase.

Iw measure error

(Iw measu)

Large offset error of the motor current

measuring in the W phase.

The error the frequency converter stopped

with cannot be defined.

If it occurs several times even after the

error has been cleared, the manufacturer

is required to troubleshooting.

Terminal 1 error

(Terminal)

Faulty parameter loading from terminal.

Loading of the proper parameter set.

Indicates error in the CAN transmissions.

(e.g. master/slave connection broken)

Check:

• if the master device is turned on and it

is set up as a master,

• CAN bus cabling

• Connections

MOD bus timeout

(MODB.to.)

In start state, the device did not receive a

message during the time set in the MOD

bus timeout.

Check:

• if the master device is turned on

• MOD bus cabling

• Connections

If the error cannot be repaired with the troubleshooting and acknowledgement described here, the manufacturer needs

to be contacted!

Loading...

Loading...