CAUTION!

Danger from incorrectly operated or inadequately maintained

pumps

Danger can arise from a poorly accessible pump due to

incorrect operation and poor maintenance.

– Ensure that the pump is accessible at all times.

– Adhere to the maintenance intervals.

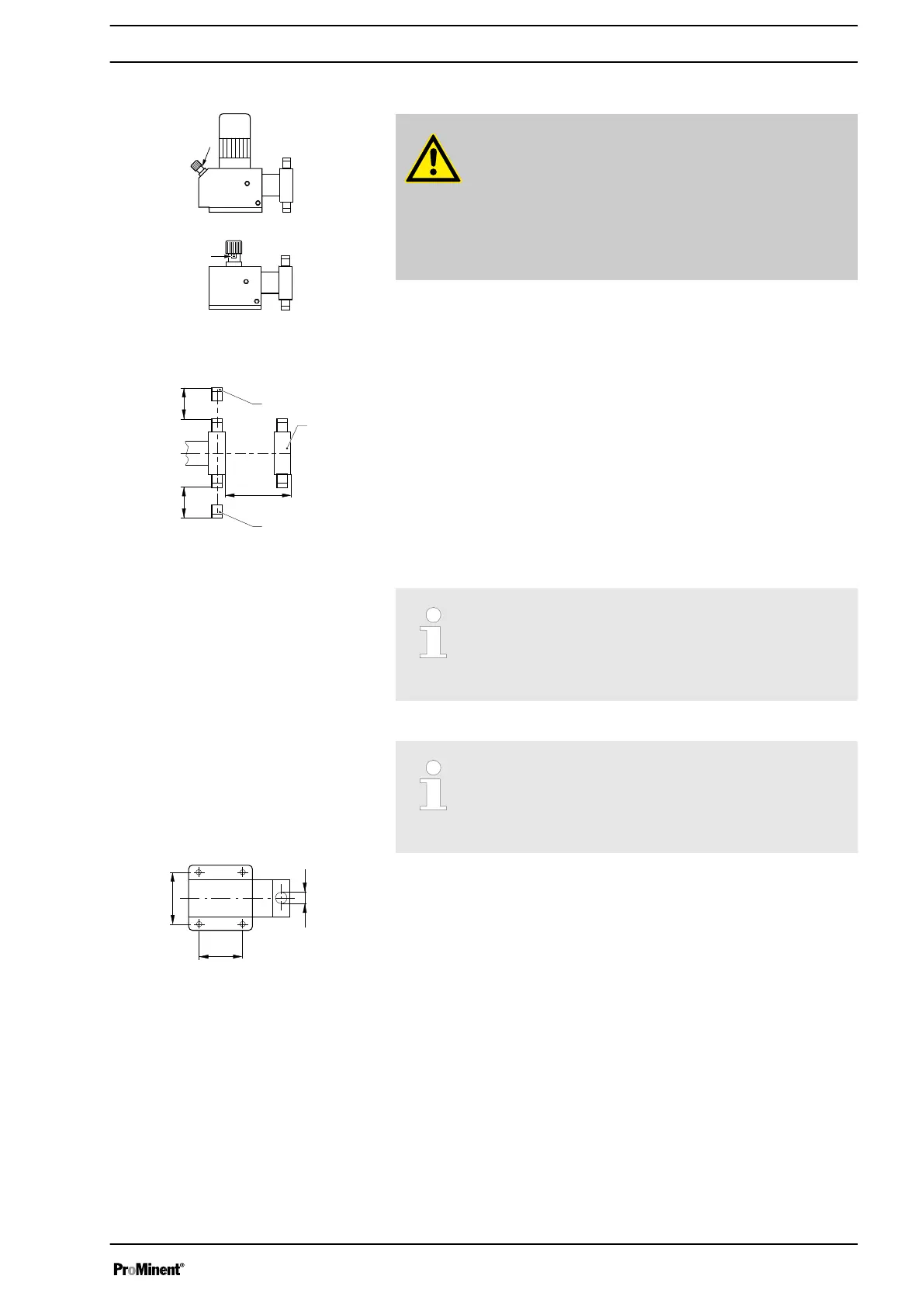

Position the pump so that control elements such as the stroke length

adjustment knob, the indicating dial A or the oil inspection window are

accessible.

In so doing, ensure there is enough space to carry out an oil change (vent

screws, oil drain plugs, oil trough ...).

1 Discharge valve

2

Dosing head

3 Suction valve

Ensure there is sufficient free space (f) around the dosing head as well as

the suction and discharge valve so that maintenance and repair work can

be carried out on these components.

Capacity too low

If the valves of the liquid end do not stand upright, they

cannot close correctly.

–

The discharge valve must be upright.

Capacity too low

Vibrations can disturb the valves of the liquid end.

–

Secure the metering pump so that no vibrations can

occur.

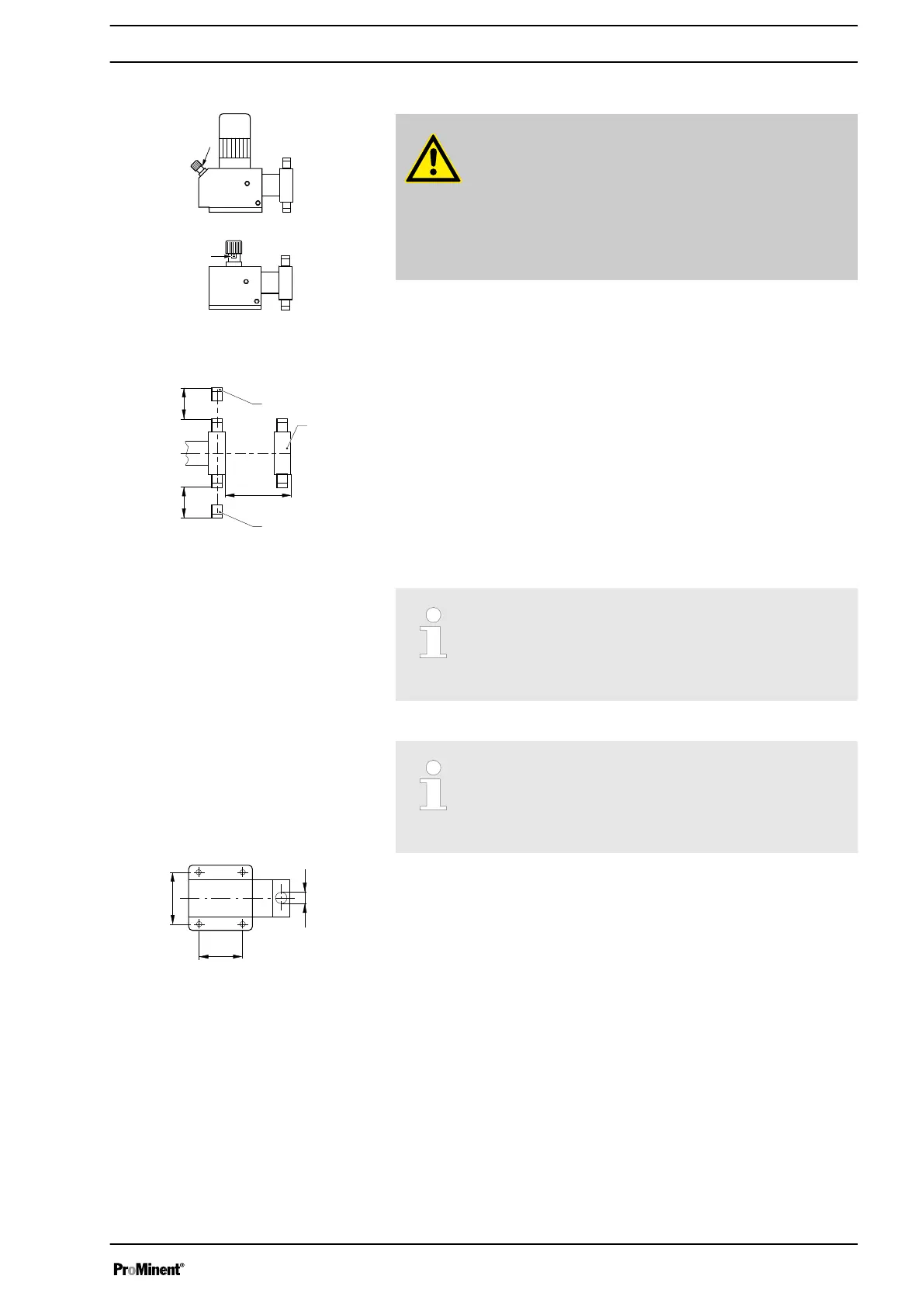

Take the dimensions (m) for the fastening holes from the appropriate

dimensional drawings or data sheets.

Fasten the pump base to the supporting floor using suitable screws.

Mounting the HMI user control

If ordered with the wall mounting, the HMI can be mounted directly on a

wall.

Mount the HMI in the direct environment of the pump. Look for good ergo‐

nomics.

When doing so, consider the available cable length.

Avoid tripping hazards.

For the dimensions of the HMI and fastening holes, see the corresponding

dimensions sheet in the "Dimension sheets" chapter.

Space requirement

Fig. 13

Fig. 14

Liquid end alignment

Fastening

Fig. 15

Assembly

29

Loading...

Loading...