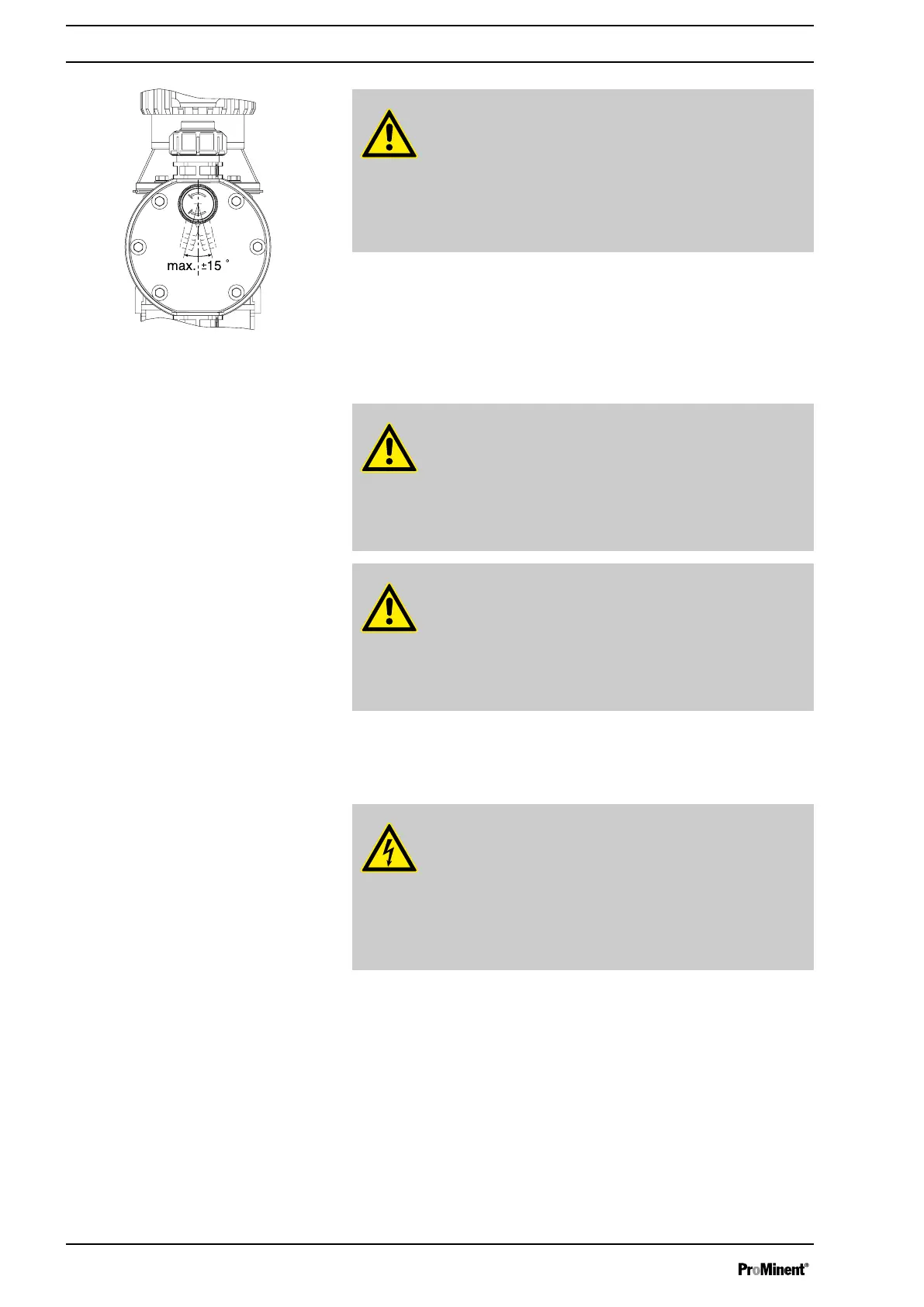

CAUTION!

Warning against leaks

Feed chemical which remains in the overflow line at the

bleeder valve, can attack the valve or cause it to leak

– Route the overflow line with a continuous slope and

moreover with the tube nozzle pointed downwards - see

Fig. 20.

CAUTION!

Danger resulting from unnoticed diaphragm rupture

If the pump has been ordered with an electric diaphragm rup‐

ture sensor, it still has to be installed.

– Screw the enclosed diaphragm rupture sensor into the

liquid end (no seal necessary).

CAUTION!

Warning of unnoticed diaphragm rupture

Only above approximately 2 bar system back pressure is a

signal generated upon a diaphragm rupture.

– Only rely on the diaphragm rupture sensor at back pres‐

sures greater than 2 bar.

7.2

Installation, electrical

WARNING!

Danger of electric shock

Unprofessional installation may lead to electric shocks.

– All cable cores cut to length must be provided with cable

end sleeves.

– The Installation, electrical of the device may only be

undertaken by technically trained personnel.

What requires electrical installation?

n Level switch

n Diaphragm rupture sensor, electrical (option)

n Dosing monitor (option)

n Relay (option)

n External control

n mA output (option)

n Bus connector (option)

n Timer (option)

n Pump, power supply

Fig. 20: Permissible alignment of the

bleeder valve

Diaphragm rupture sensor

General safety notes

What requires electrical installation?

Installation

34

Loading...

Loading...