7.2.1

Control connectors

CAUTION!

Incoming signals can remain without effect

If the universal control wire, the external/pacing cable or the

level monitoring cable is shortened below 1.20 m, the pump

does not detect that it is connected. Consequently a warning

message (for example) can be suppressed.

– Do not shorten this cable below 1.20 m.

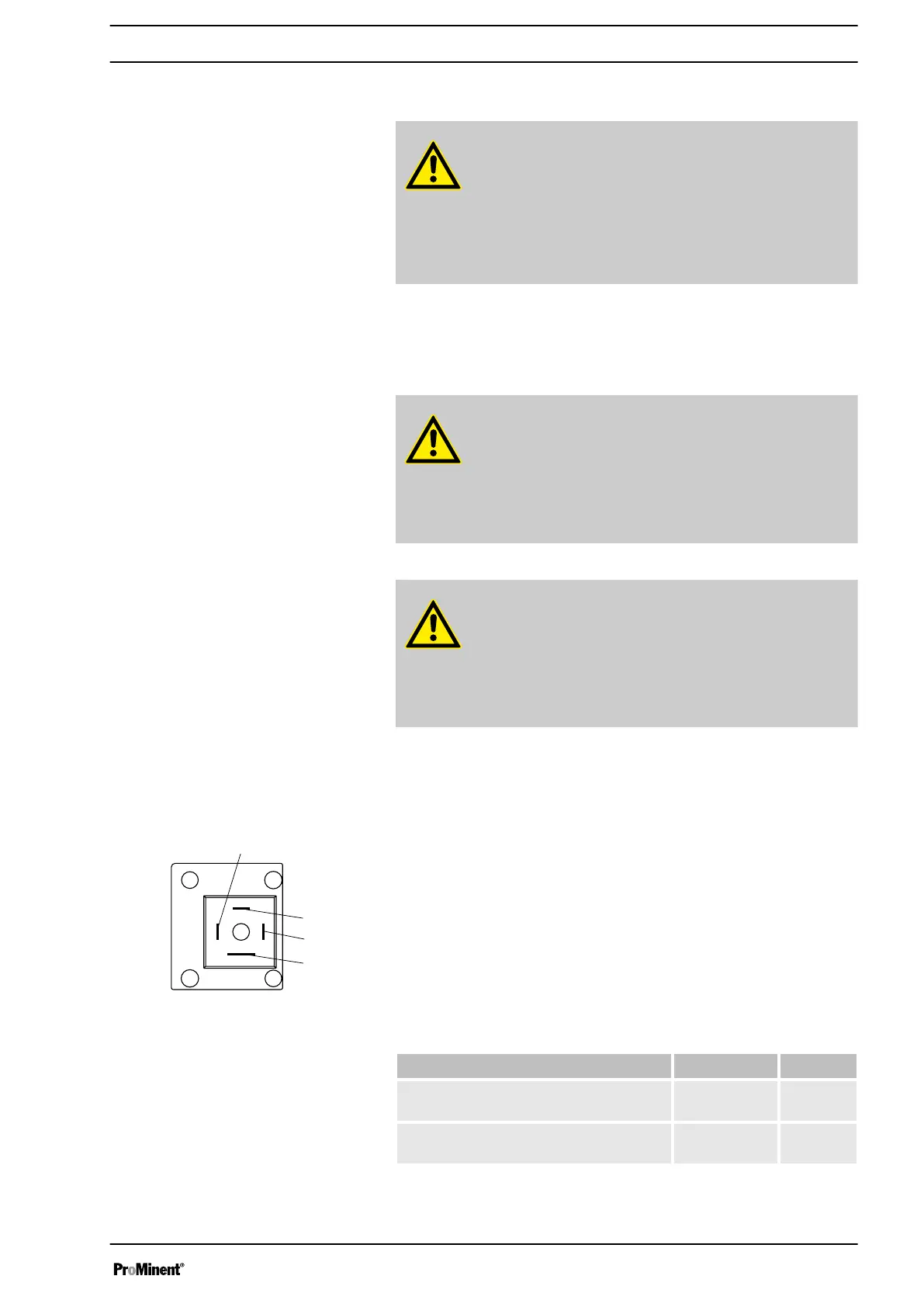

Connect the plugs of the level switch, diaphragm rupture sensor and

dosing monitor to the corresponding sockets on the front side of the con‐

trol. In case of uncertainty - see chapter "Overview of equipment and con‐

trol elements"

CAUTION!

Danger resulting from unnoticed diaphragm rupture

If the pump has been ordered with an electric diaphragm rup‐

ture sensor, it must also be electrically installed.

– Electrically connect the enclosed diaphragm rupture

sensor.

Only with combustible media:

CAUTION!

Fire danger

The electric diaphragm rupture sensor must stop the pump

immediately after a diaphragm rupture and trigger an alarm.

The pump must only be returned to service once a new dia‐

phragm has been fitted.

7.2.1.1

Relay

7.2.1.1.1

Output relay

If another switching function is required, the pump can be reprogrammed

in the

‘Relay’

menu.

The relay can be retrofitted and operates once it is plugged into the relay

board.

Data Value Unit

Maximum contact load at 230 V and 50/60

Hz:

8 A (resis‐

tive)

Minimum mechanical lifespan: 200 000 Switching

operations

Level switch, diaphragm rupture sensor

(option) and dosing monitor (option)

Fig. 21: Pump pin assignments

Output relay

Installation

35

Loading...

Loading...