14.2

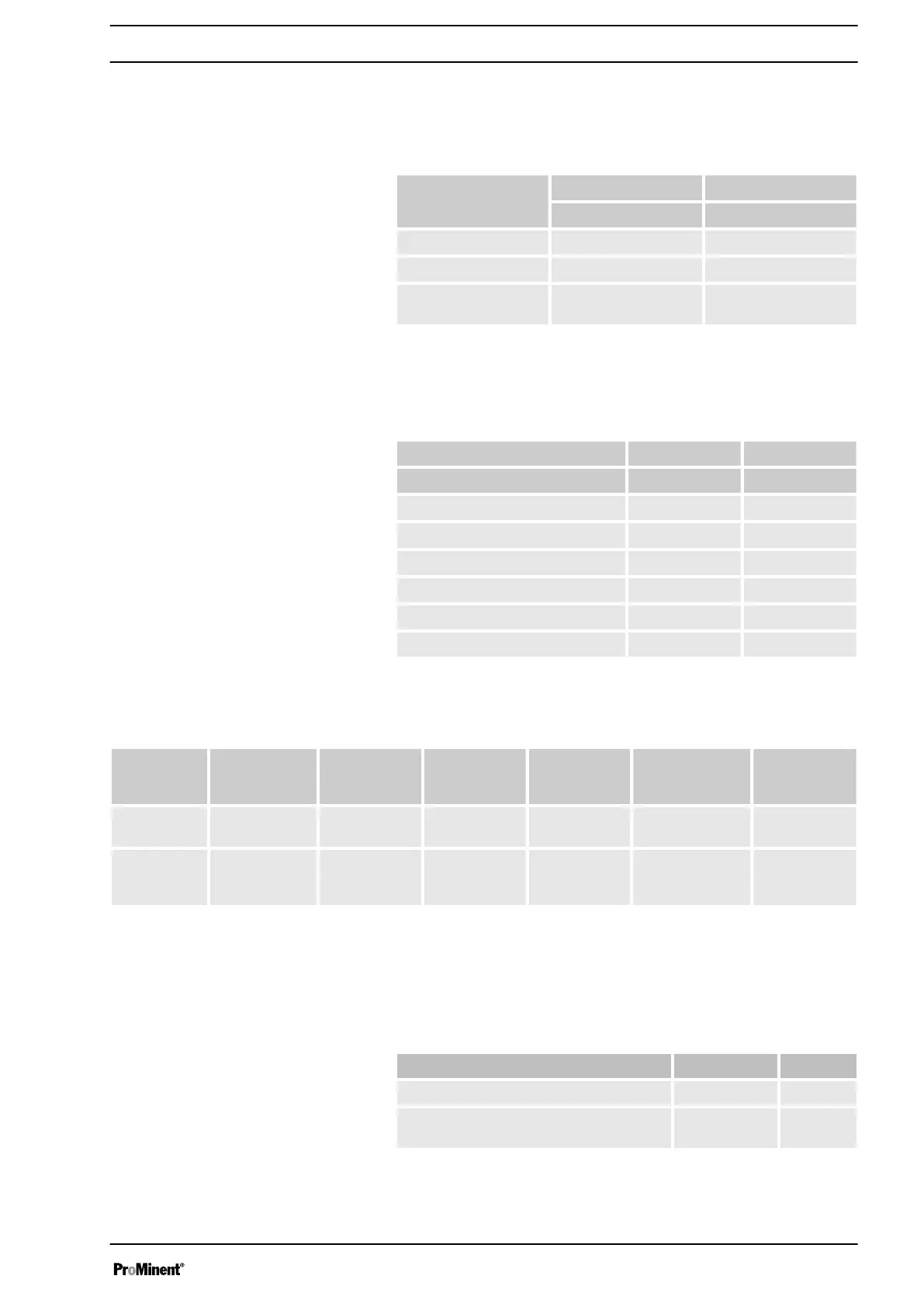

Viscosity

The liquid ends are suitable for the following viscosity ranges:

Version Stroke rate, max. Viscosity

Strokes/min mPas

Standard 180 0 ... 200

With valve springs 130 200 ... 500

With valve springs and

suction-side feed

90 500 ... 1000*

* Only when the installation is correctly adjusted

14.3

Shipping weight

Types Material version Shipping weight

kg

12017; 12035; 10050 PVT 9.8

SST 11.7

10022; 10044; 07065 PVT 9.8

SST 11.7

07042; 04084; 04120 PVT 10.0

SST 13.2

14.4

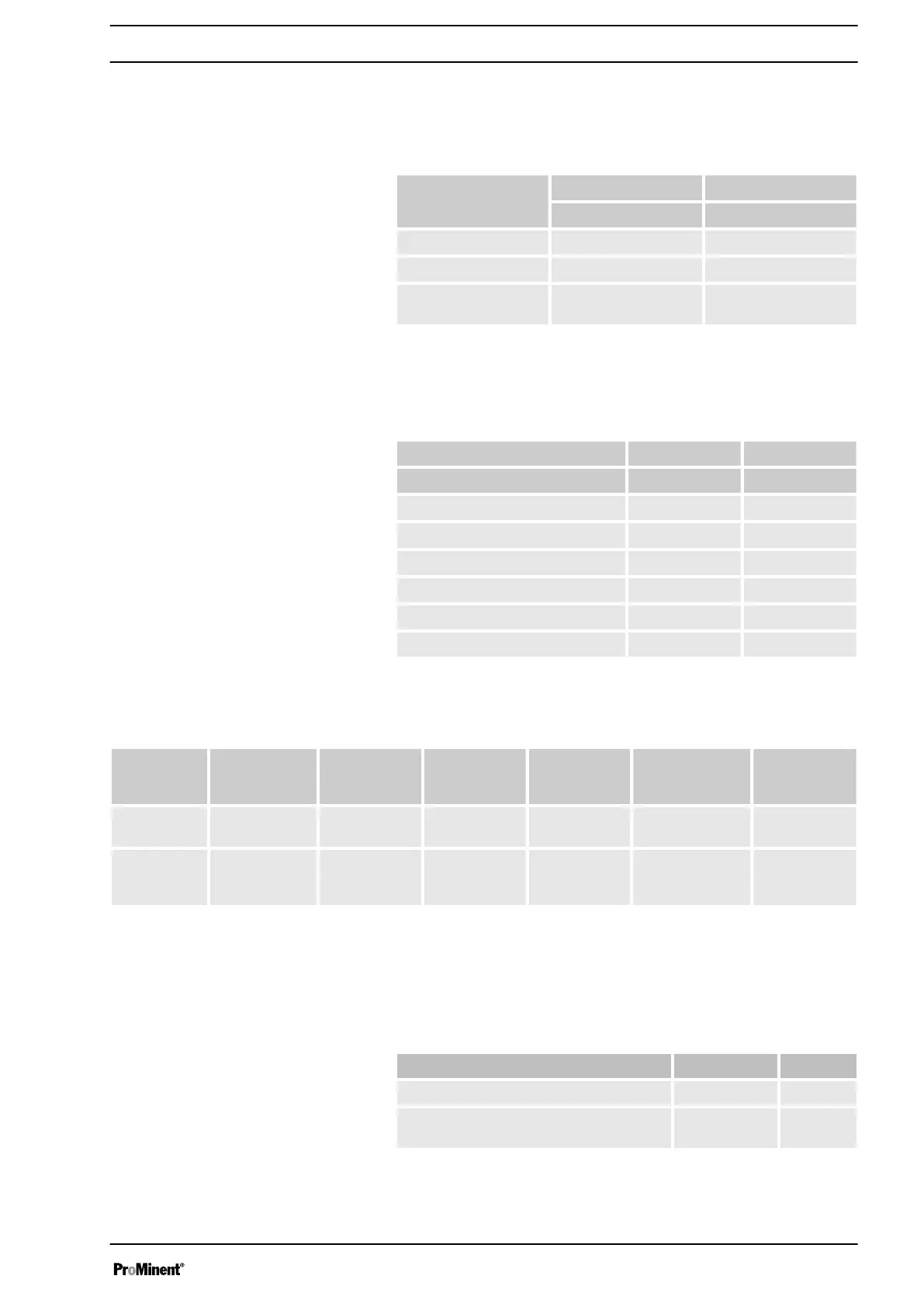

Wetted materials

Material ver‐

sion

Liquid end Suction/dis‐

charge con‐

nector

Seals* / ball

seat

Balls Springs Integral relief

valve

PVT PVDF PVDF PTFE/PTFE Ceramic Hastelloy C PVDF / FPM

or EPDM

SST Stainless steel

1.4404

Stainless steel

1.4581

PTFE/PTFE Stainless steel

1.4404

Hastelloy C Stainless

steel / FPM or

EPDM

* Metering diaphragm is PTFE coated

14.5

Ambient conditions

14.5.1

Ambient temperatures

Data Value Unit

Storage and transport temperature -10 ... +50 °C

Ambient temperature in operation (drive +

motor):

-10 ... +45 °C

Pump, compl.

Technical data

81

Loading...

Loading...