CAUTION!

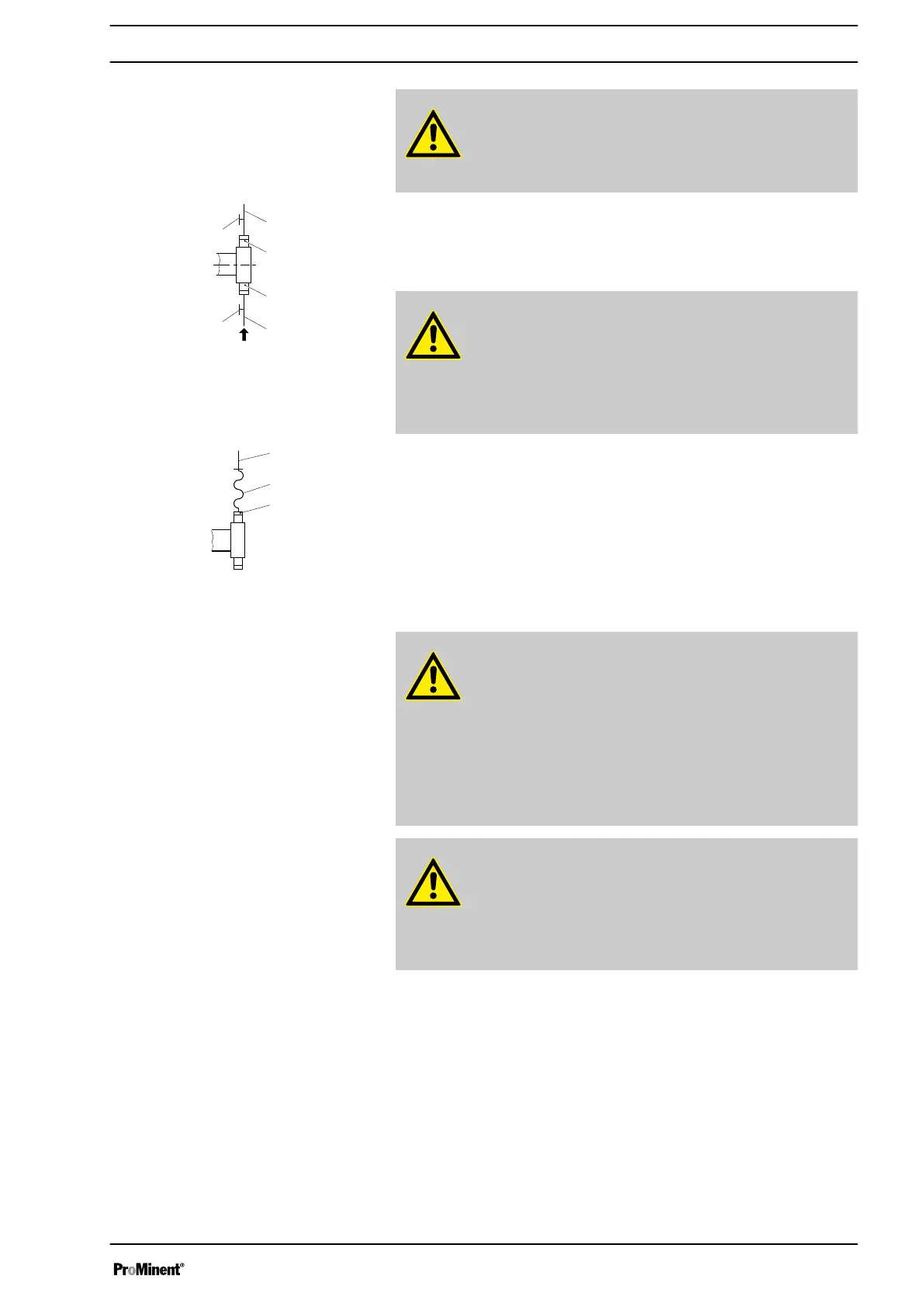

To check the pressure conditions in the piping system it is

recommended that connecting options are provided for a

manometer close to the suction and pressure connector.

1 Manometer socket

2 Discharge line (pipe)

3 Discharge valve

4 Suction valve

5 Suction line (pipe)

CAUTION!

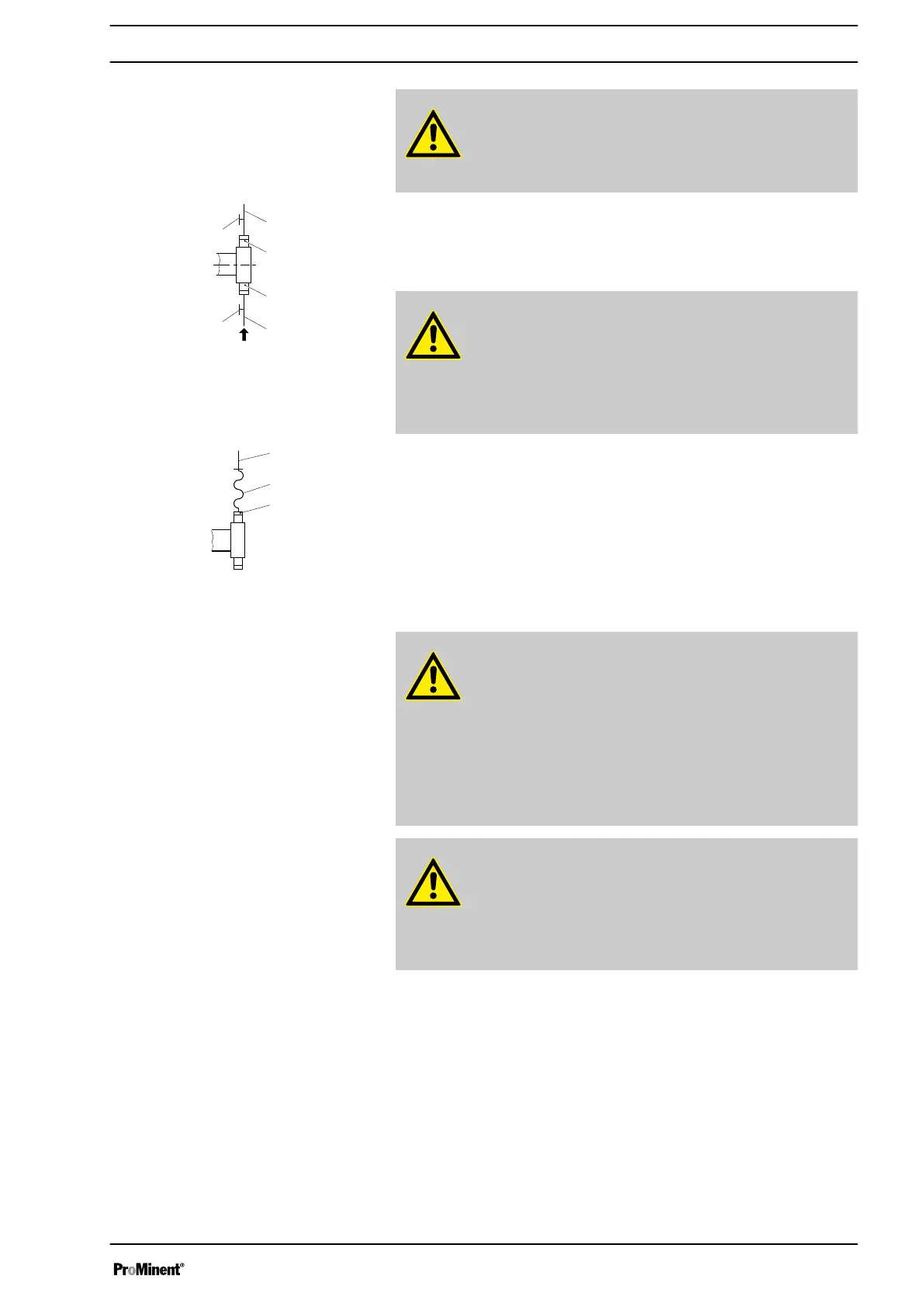

Connect the pipelines to the pump so that no residual forces

act on the pump, e.g. due to the offsetting, weight or expan‐

sion of the line.

Only connect steel or stainless steel piping via a flexible

piping section to a plastic liquid end.

1 Steel pipeline

2 Flexible pipe section

3 Plastic liquid end

CAUTION!

Warning of feed chemical spraying around

If no overflow line was connected to the integral bleeder

valve, feed chemical sprays out of the tube connection as

soon as the bleeder valve opens.

– An overflow line must always be connected to the inte‐

gral bleeder valve and be fed back to the storage tank or

- if required by the regulations - into a special storage

tank.

CAUTION!

Danger of cracking

Cracking of the PVT liquid end can occur if a metal overflow

line is connected to the bleeder valve.

– Never connect a metal overflow line to the bleeder valve.

Fig. 18: Manometer connecting options

Fig. 19: Steel pipeline at the liquid end

Integral bleeder valve

Installation

33

Loading...

Loading...