Plot a diagram similar to the one above - with values for (I1,

F1) and (I2, F2) – so that you can set the pump as desired!

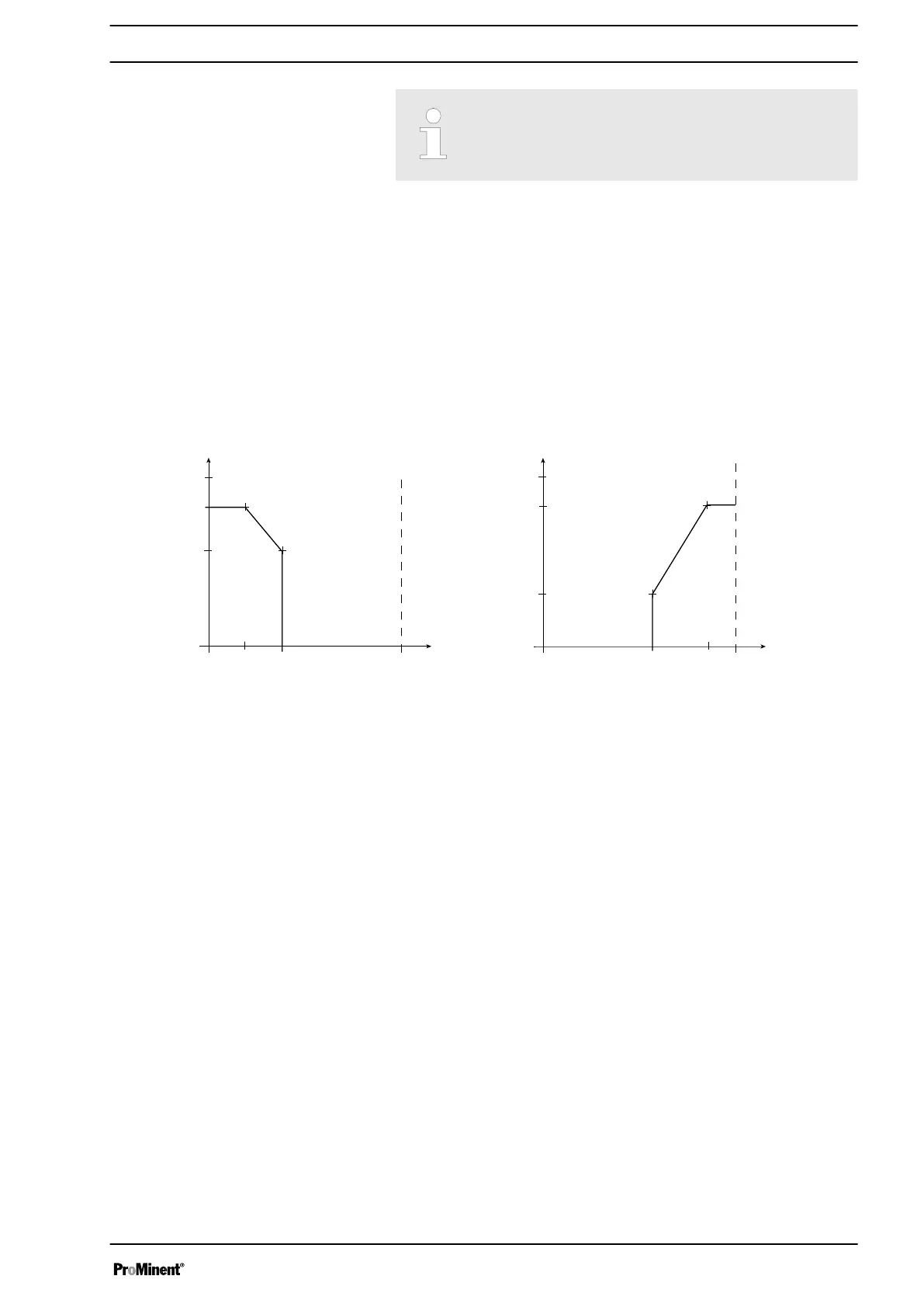

‘Lower sideband’

Using this processing type, you can control a metering pump using the

current signal as shown in the diagram below.

However, you can also control two metering pumps for different feed

chemicals via a current signal (e.g. one acid pump and one alkali pump

using the signal of a pH sensor). To do this, you must connect the pumps

electrically in series.

The "Lower sideband" symbol appears in the LCD display. Below I1, the

pump works at a rate of F1 - above I2 it stops. Between I1 and I2 the

stroke rate varies between F1 and F2 in proportion to the signal current.

I [mA]

I 1 I 2

F2

F1

0 20

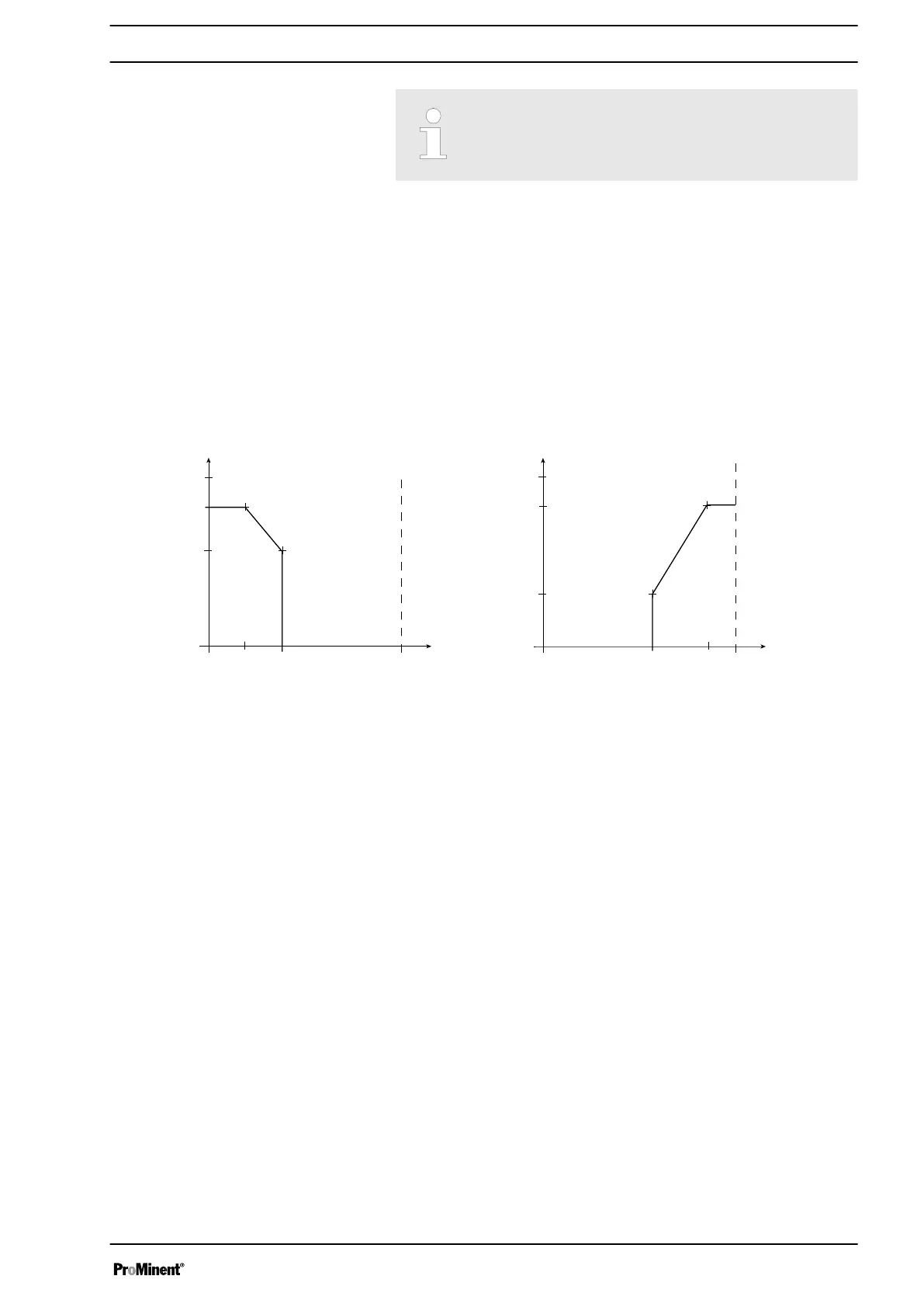

a) b)

P1

P2

Fmax

B0089

I [mA]

I 1

I 2

F1

0 20

P1

P2

F2

Fmax

Fig. 30: Frequency-current diagram for a) Lower sideband, b) Upper sideband

‘Upper sideband’

Using this processing type, you can control a metering pump using the

current signal as shown in the diagram above.

However, you can also control two metering pumps for different feed

chemicals via a current signal (e.g. one acid pump and one alkali pump

using the signal of a pH sensor). To do this, you must connect the pumps

electrically in series.

The "Upper sideband" symbol appears in the LCD display. Below I1, the

pump is stationary - above I2 the pump works at rate F2. Between I1 and

I2 the stroke rate varies between F1 and F2 in proportion to the signal cur‐

rent.

Under menu option

‘Analog error’

you can activate error processing for

processing type

‘Curve’

. For current signals below 3.8 mA, a fault mes‐

sage appears and the pump stops.

Fault processing

Set-up

53

Loading...

Loading...