Page 76 of 76 Service & Calibration

4.3.1 1855 Verification Procedure

This section outlines the relevant information to verify performance of the 1855 Meter. It is

recommended that performance be performed at least once a year using this outline procedure.

Instrument should be warmed up for a minimum of 15 minutes prior to verification. Verification

should be performed under the following conditions: Temperature equal to 23°C ±1.2°C and

Relative Humidity (RH) between 35% and 55%.

Recommended standards are listed below. All standards should be traceable to a National

Laboratory (such as NIST) and have calibrated values for primary and secondary parameters at

the required test frequencies. QuadTech’s verification conforms to ANSI Z540 and QuadTech

recommends that the calibrated values for the primary and secondary standards have an

uncertainty 4 times better than the primary and secondary accuracy specified in the Verification

Data Sheet. If the calibrated values for the standards used do not have an uncertainty of 4 times

better than the specified accuracy of the 1855 the uncertainty of the standard should be added to

the specified accuracy of the 1855.

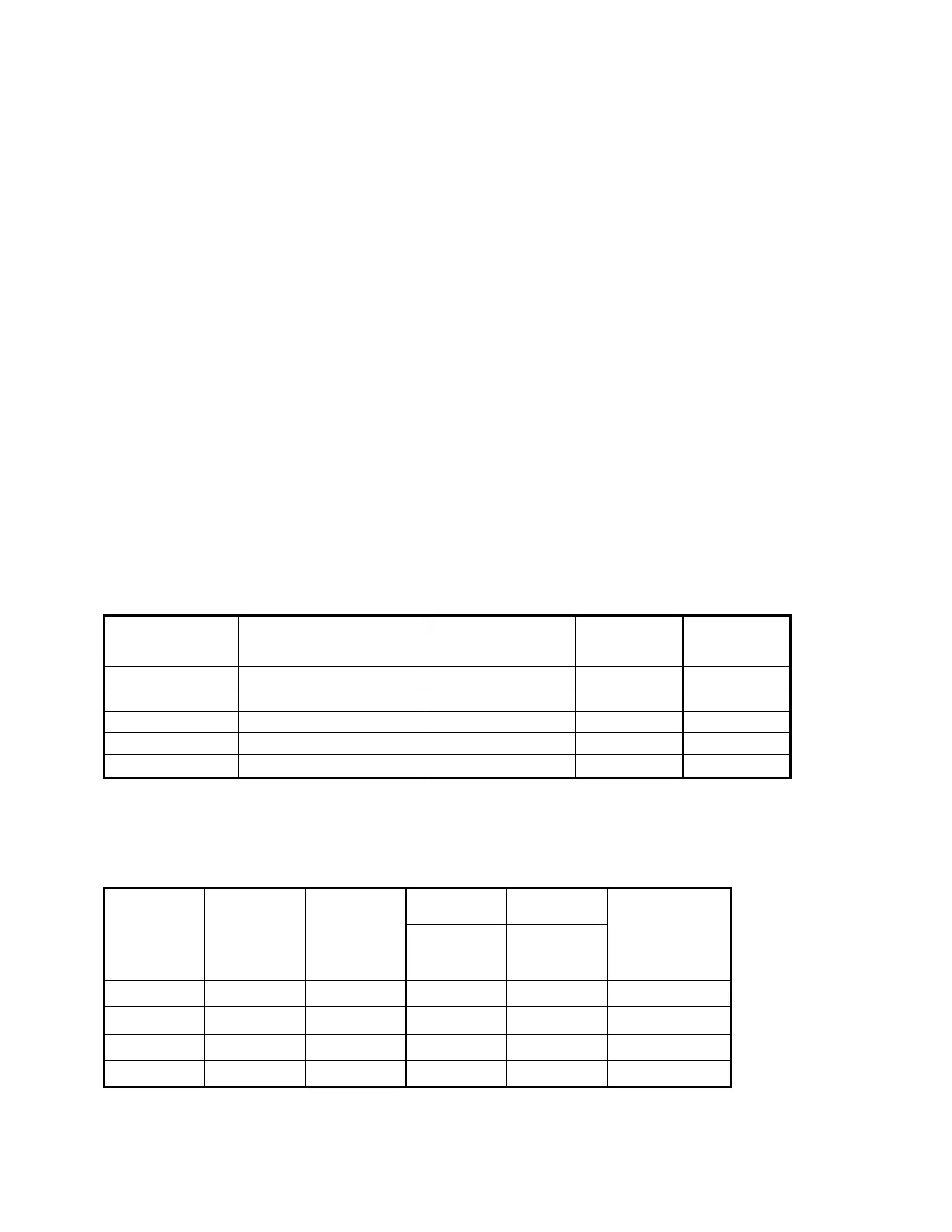

4.3.2 1855 Verification Data Sheet

Out Voltage: @ 10mA

(Verify Display & Measured Values are within high and low limits)

(Note: MEASURE between RED (+) and WHITE (-) mounting jacks)

Voltage Setting

(V)

Measured

Voltage (Fluke)

Displayed

Voltage (1855)

Low Limit

Voltage

High Limit

Voltage

1 795mV 1.205V

50 49.55V 50.45V

200 198.8V 201.2V

400 397.8V 402.2V

600 596.8V 603.2V

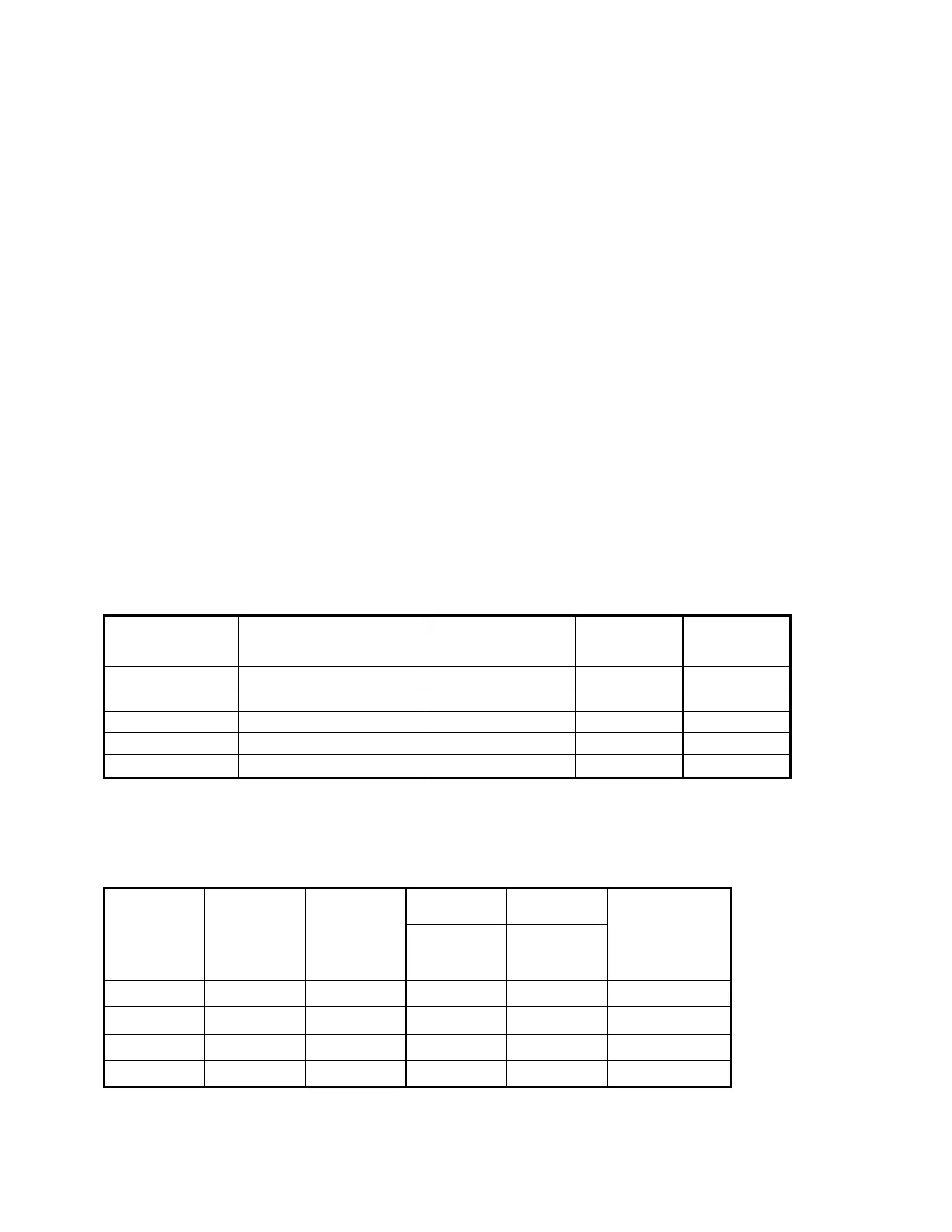

IR Measurement: @ .5mA

(Note: MEASURE between BNC jack and WHITE (-) mounting jacks)

Before After Voltage

Setting

(V)

Nominal

Resistance

(Ω)

Actual

Resistance

(Ω)

Displayed

Value

(Ω)

Displayed

Value

(Ω)

Test

Specifications

100V 10M 0.805%

100V 100M 0.854%

200V 1G 0.973%

500V 1G 0.747%

Loading...

Loading...