72

CAMERA & GIMBAL

PAYLOAD REPLACEMENT

Both the FLIR Hadron EO/IR camera and gimbal are

replaceable in the field. Use the specific tools to

prevent damaging parts in the repair process.

CAMERA & GIMBAL REPLACEMENT INSTRUCTIONS

1. Place the drone on its back on a table or

workspace. Hang the antenna off the edge of

the table to prevent damage.

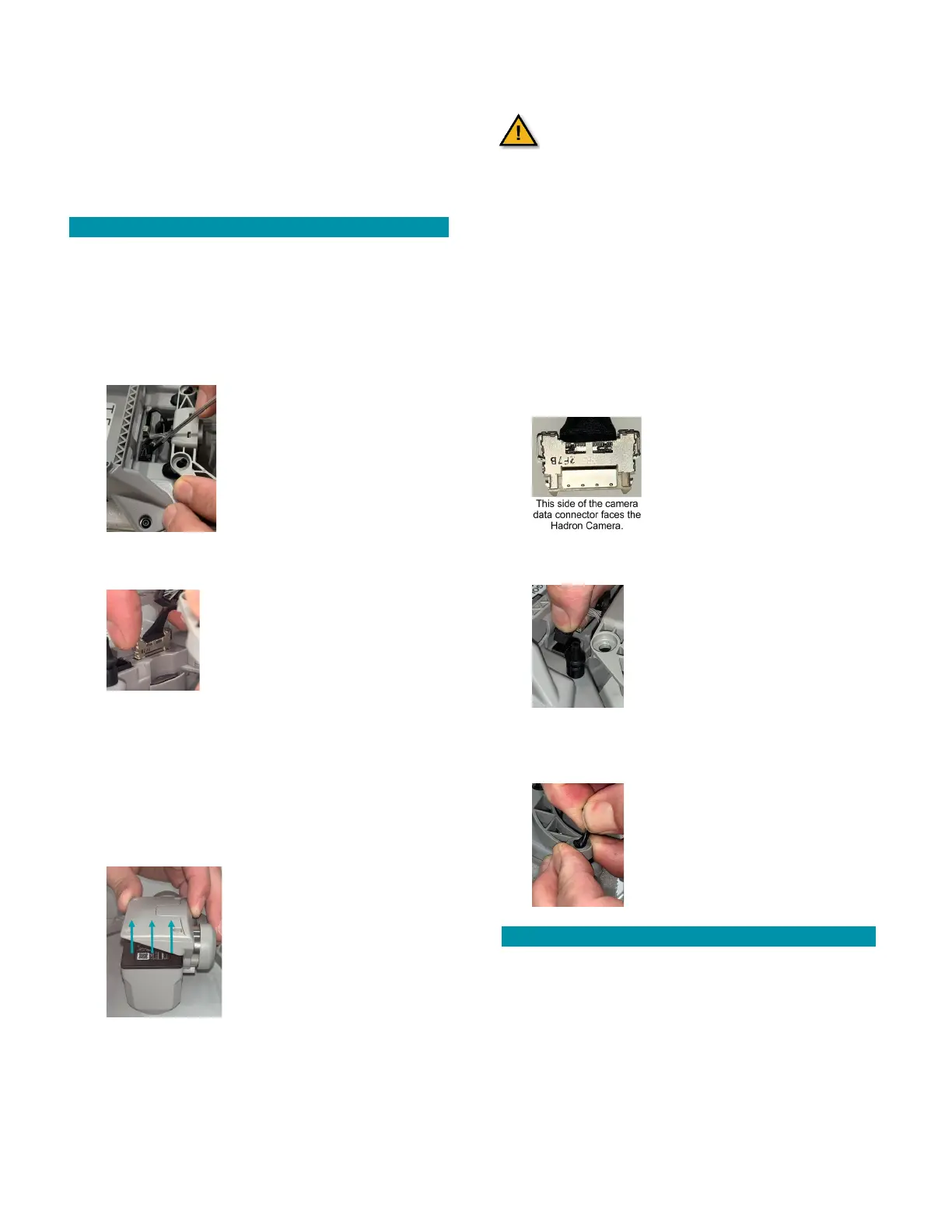

2. Remove the four rubber grommets

gimbal brackets. Use a screwdriver to push the

grommets through the hole.

3. Use your fingernail or a

screwdriver to press

the tab on the motor

cable connector.

4. Pull the connector straight up to disconnect it

from the socket.

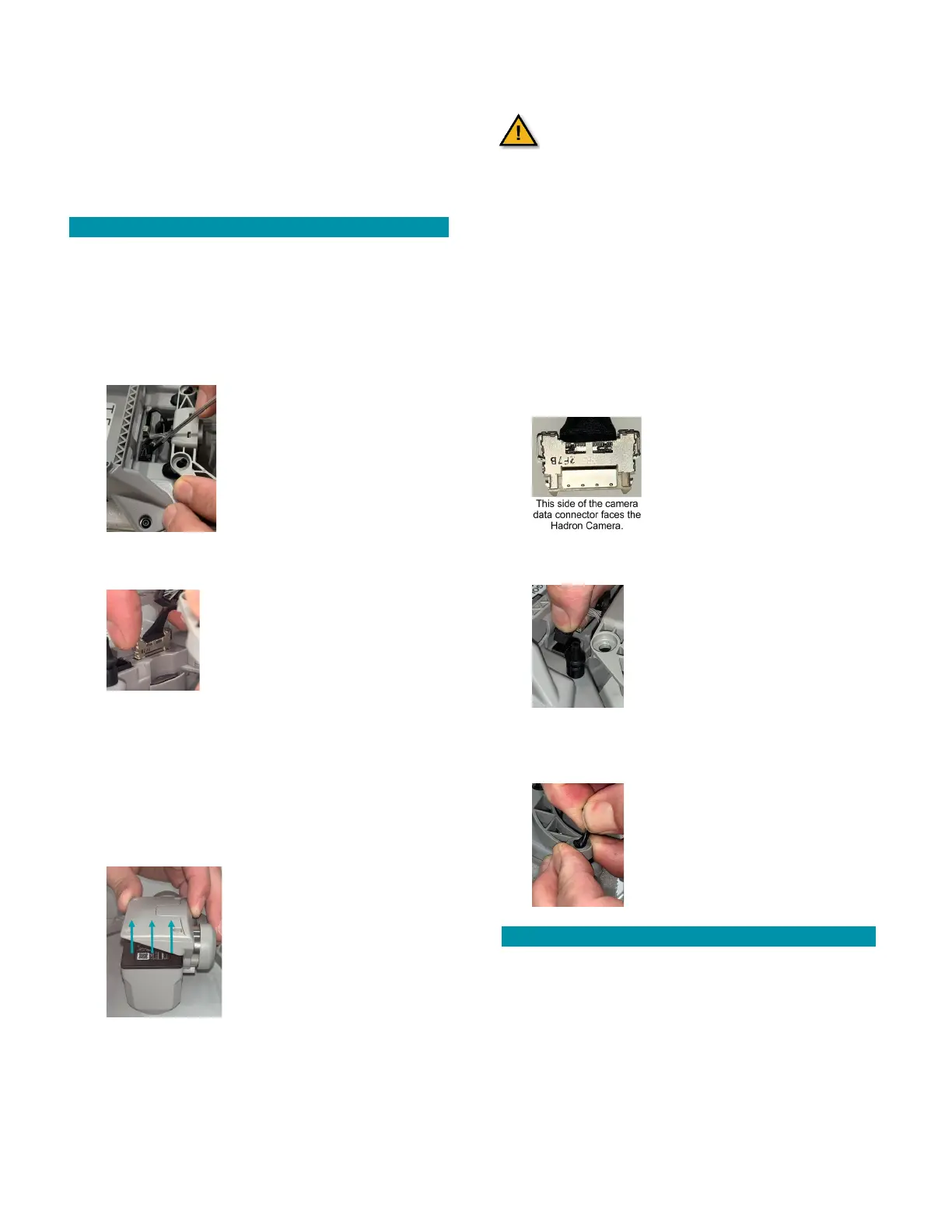

5. Squeeze

the side

latches of the camera

data cable connector to

release it.

6. Pull the connector straight up to disconnect it

from the socket.

7. Use a T5 Torx screwdriver to remove the four

M1.6 x 0.35mm screws from the back of the

Hadron camera. Set the screws aside for re-use.

8. Pull the Hadron camera

away from the gimbal.

The exposed PCB is ESD sensitive and static

discharge can damage the electronics.

Minimize handling of the exposed PCB.

9.

Check the gasket around the PCB on the

Hadron camera is properly aligned. Adjust if

needed.

10. Push the Hadron camera onto the gimbal. Press

straight down until you feel the connector click

into place.

11. Use a T5 Torx screwdriver to secure the four

M1.6 x 0.35

mm screws in the back of the

Hadron camera.

data cable connector to

the drone. The side of

the cable

toward the front of the

drone.

motor cable connector

to the mating socket in

the drone. The tab on

the connector faces the

front of the drone.

14. Align the rubber grommets on the gimbal under

the holes on the gimbal brackets.

rubber grommets

holes.

SYSTEM CHECKOUT

1. Manually move the gimbal pitch and roll

axis and check for binding or obstructions.

2. Check that no wires are pinched.

3. Power on the system and confirm the

gimbal properly functions and is properly

oriented.

SYSTEM CHECKOUT

Loading...

Loading...