120

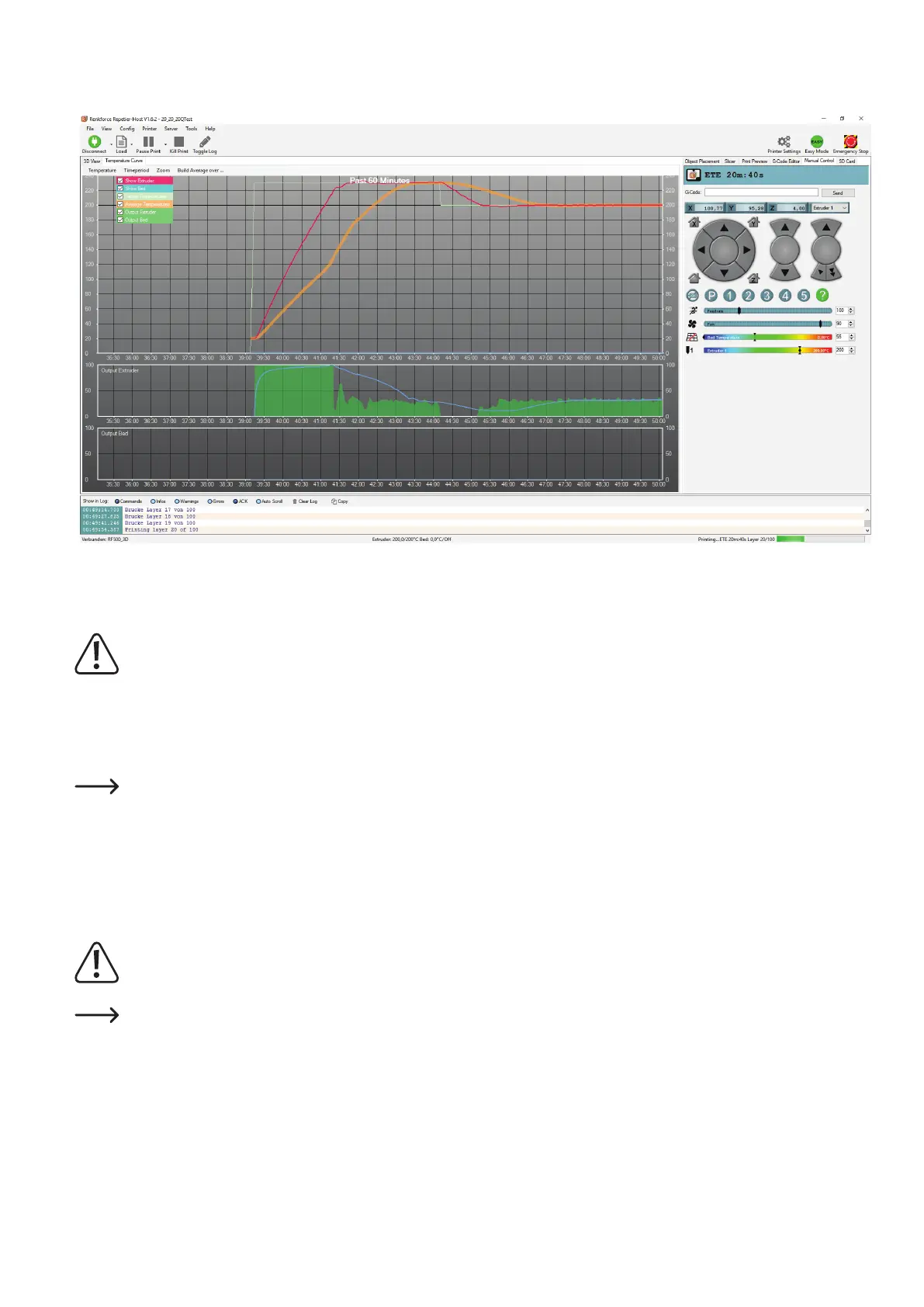

The graphics window may be switched to display temperature curves. There, the temperatures and their course are graphically displayed in a

chart.

Duringtherstcentimetresofprinting,thedistancebetweentheprintingplatesupportandextrudercanbecarefullyne-adjustedmanuallywith

the 4 knurled screws at the bottom of the pressure plate. Turn all 4 knurls alternatingly and observe the printed line.

Forthissetting,observethattheextrudermustnottouchtheprintingplatesupportsinceitmaybedamagedotherwise

(lossofwarranty/guarantee).

Itispossiblethatlamentchipscollectovertimeatthelamentfeedknurl.Theyshouldberemovedunderallcircumstanc-

es(ifpossible)atonce,e.g.byblowingoff.Checkandcleanthelamentfeedknurlregularly!Otherwise,itispossiblethat

thechipswilladheretotheknurlandthatnolamentcanbeconveyedanymorebecauseofthis(theknurlslipsthrough

then).

The fan at the extruder runs by default from 4th layer for PLA and ABS, provided that the slicer settings have not been changed.

If the fan does not run properly, check if it may be attached unevenly.

When you use the preassembled device or the optional heating plate kit,

let the printed object cool off for a few minutes after printing. When

thetemperatureoftheheatingplateisbelow40°C(seedisplay),theprintedobjectcomesfreefromtheheatingplateandyoucanremoveit.

If the printed object does not come loose easily, you can loosen it carefully with a glass scraper, razor blade spatula, knife, etc.

Donotapplyanymechanicalforcetotheprintingplateortheprintingplatesupport,sincethismaydamagetheprinting

plate,ortheglassplate(onlymakerconstructionkit)maybreak!Lossofguarantee/warranty!

To ensure stable operation, print from SD card for longer printouts. Otherwise, it is possible that printing is interrupted because the

printer is restarted via the USB interface. This can be caused by restarting the PC, re-initialising the USB controller or by a virus

scanner.

Loading...

Loading...