136

Cleaningtheprintingplate

Becarefulinthepreassembleddeviceorwhenusingtheoptionalheatingplatekit:Dangerofburns.Lettheheatingplate

cool off before cleaning.

Clean and degrease the heating plate thoroughly with a soft rag after each print. If you are printing directly on the glass panel, use a little ac-

etoneforcleaning.Ifyouareusingtheadhesivelmuseamilddetergentwithalcohol.

e)NozzleChange

Caution:Dangerofburns.Donotdirectlytouchthehotnozzleandtheextruder.

• Toreplacetheextrudernozzle,theextrudermustrstbeheatedtoatemperaturesuitablefortheinsertedlamentmaterial.

• Whenthetemperatureisreached,removetheinsertedlamentmaterialasdescribedinchapter"16.c)RemovingandChangingtheFila-

ment".

For the sake of simplicity, we have removed the fan sheet for the pictures.

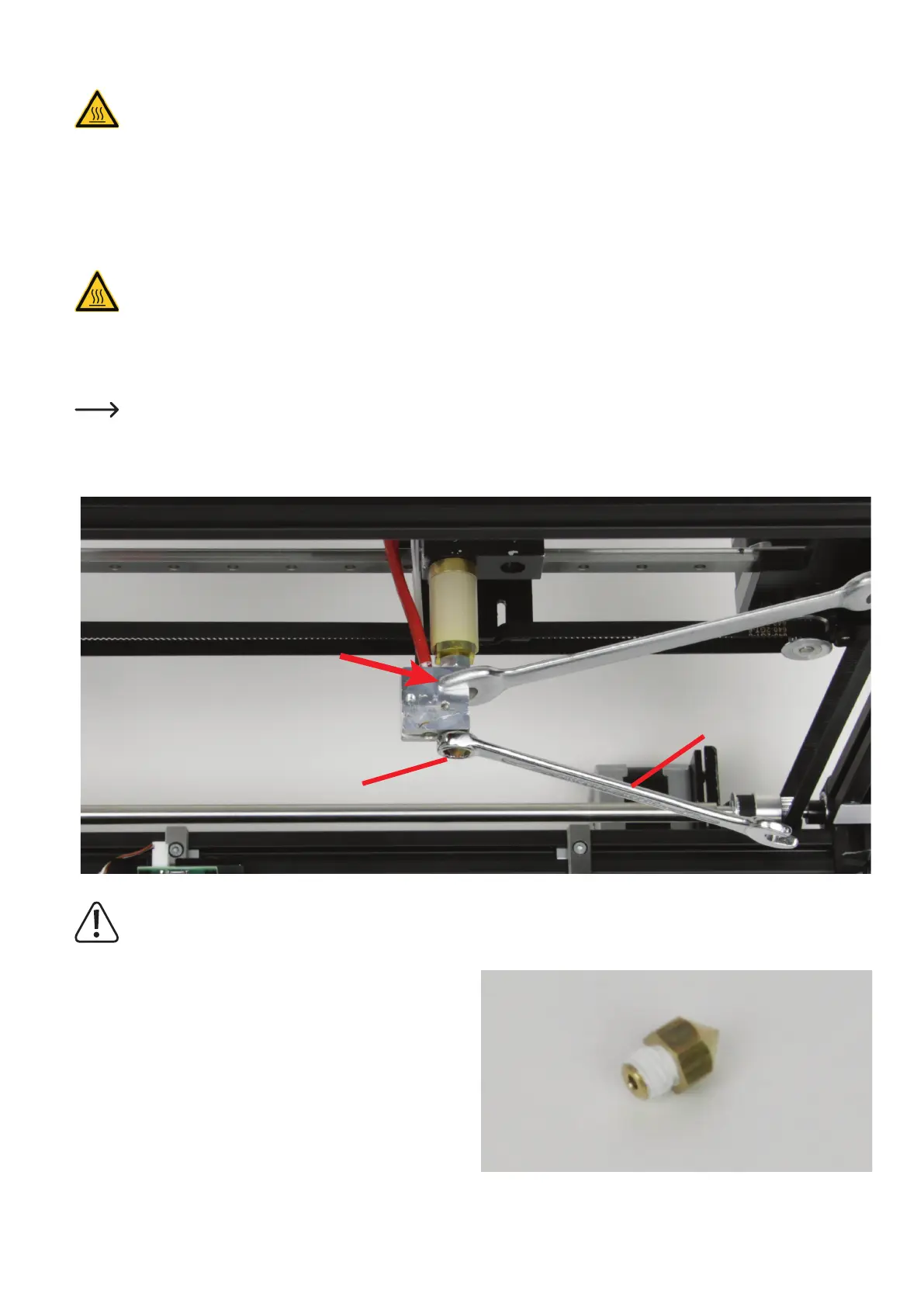

• Screwofftheextrudernozzle(1)fromtheextruderwithan8mmringspanner,open-facedspannerorhexagonwrench(2).Securetheheat-

ing block against twisting with an 11 mm open-faced spanner. Do not damage the lines of the temperature sensor.

Theextrudermustnottwistduringnozzlechangeandthenozzlemustneverbeturnedwhencoldsincetheextrudermay

otherwisebedamagedandrendereduseless.

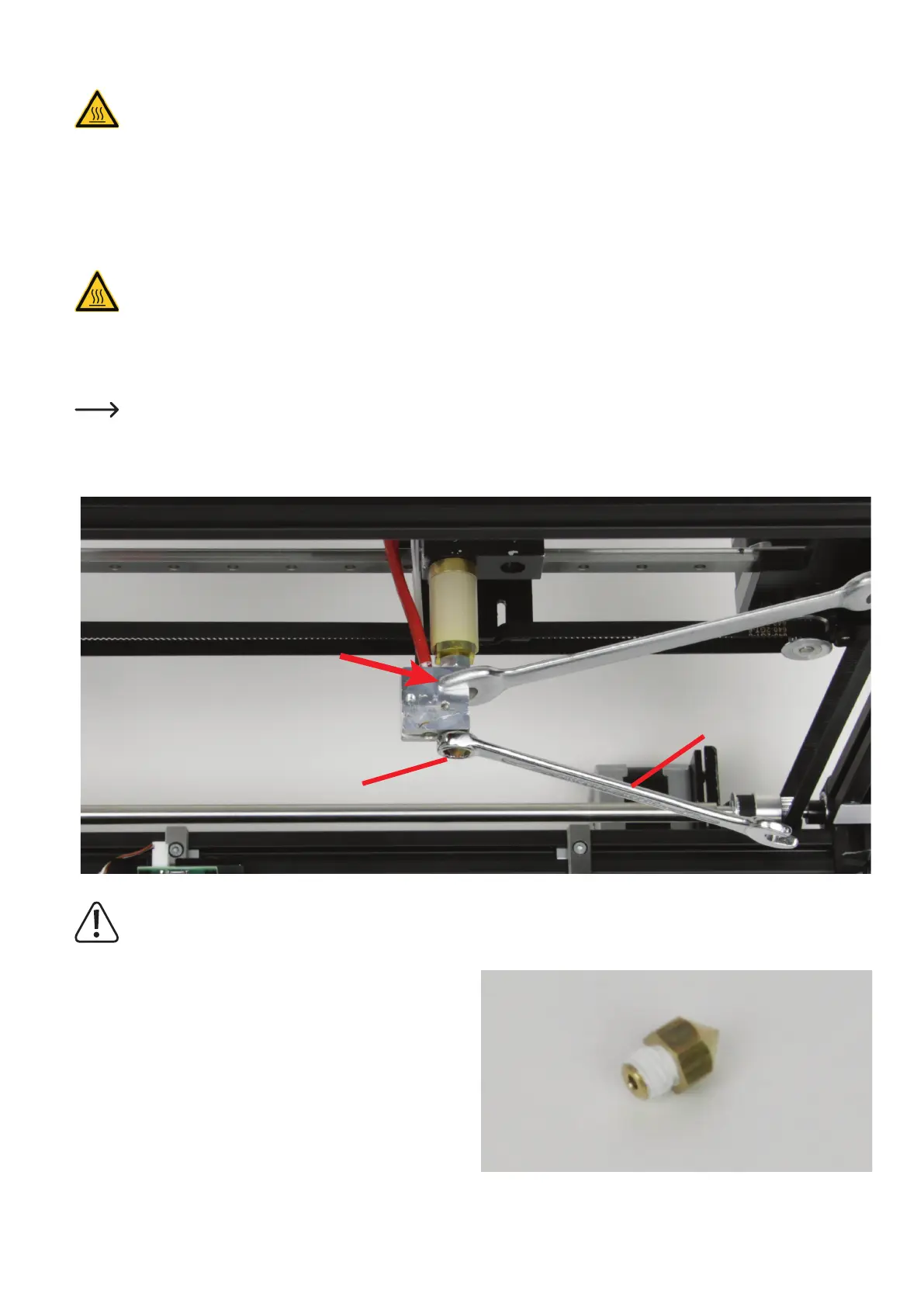

• Cutabout2to3cmthreadsealingtapeoffoftherollandwindit

around the thread of the new nozzle. Cut off the sealing tape that

protrudes over the thread with a sharp knife, e.g. by running the knife

along the upper-most groove of the thread.

The sealing tape must never protrude beyond the thread.

1

2

Loading...

Loading...