107

5.2.1 General points to be checked

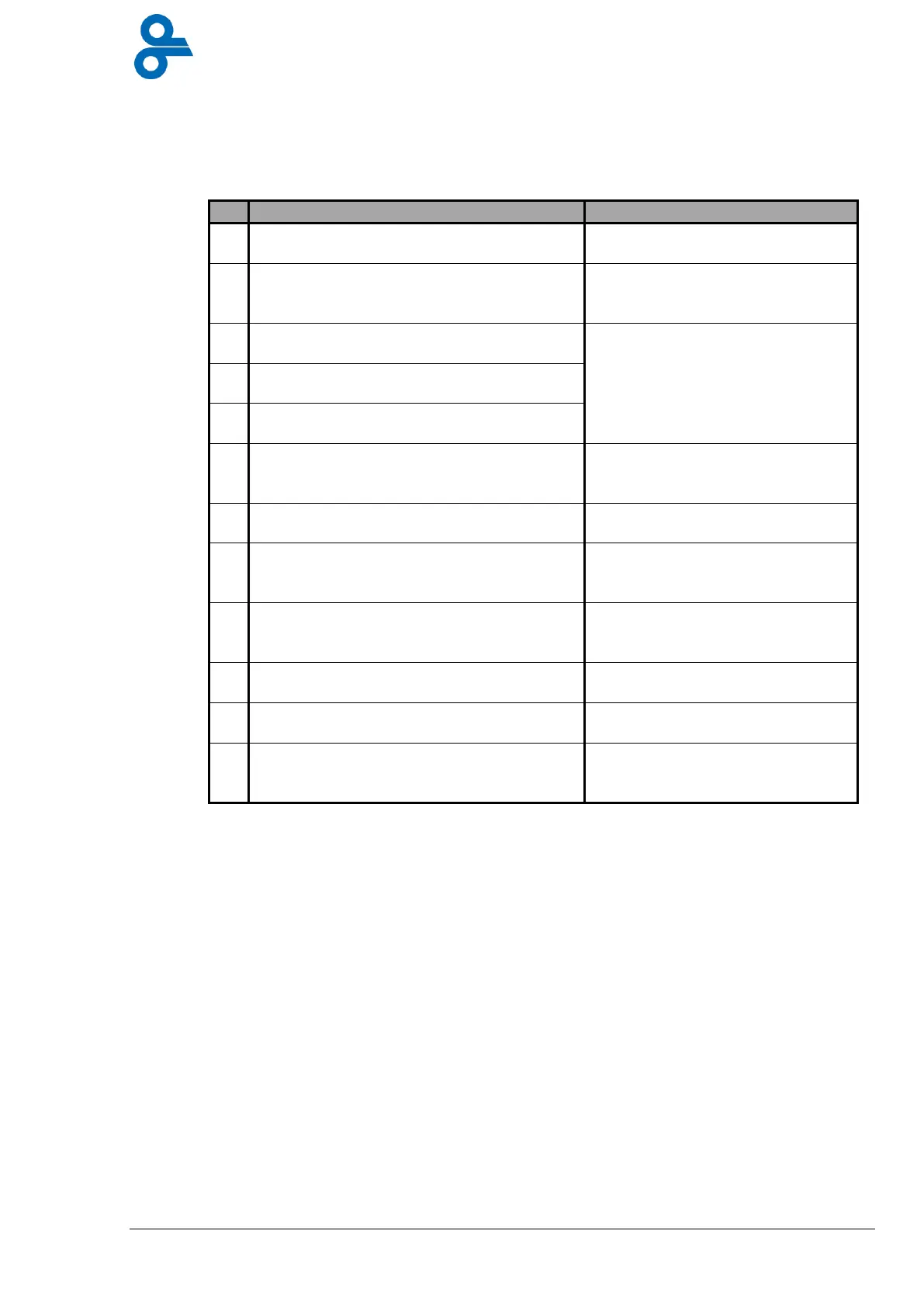

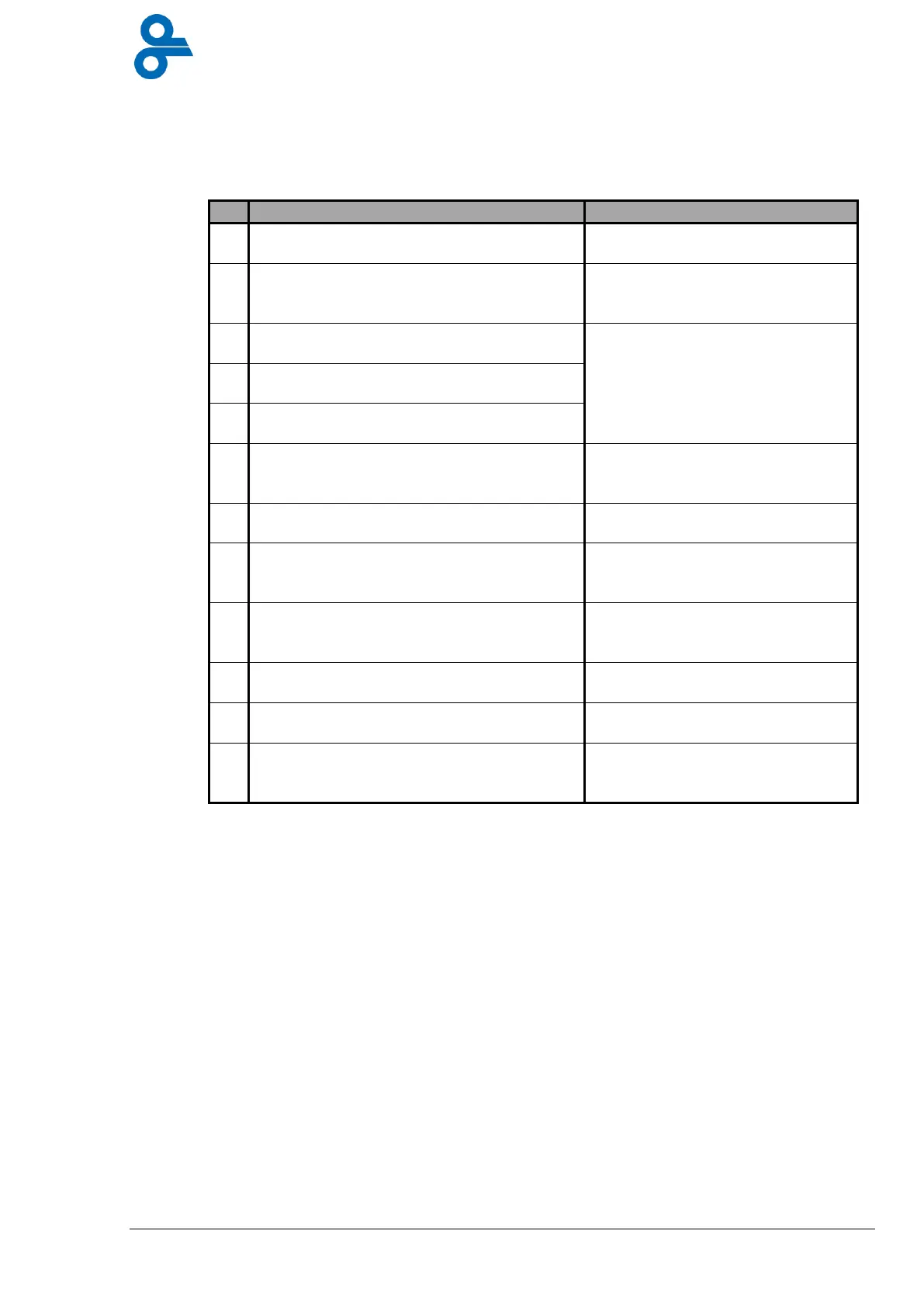

Table 4 states general points that have to be checked before the machine is turned on. This

helps prevent problems in starting up and running the machine.

Table 4 Points to check when turning the machine on

Format parts must be in place.

Check the connections for the

format parts.

Cover plates must be in place.

Each plate has its own unique

place and can only be positioned

in a certain way.

Check cooling water supply: the tap must

be turned on.

Open external supply taps if

necessary.

Check compressed air supply: the tap

must be turned on.

Check protective gas supply: the tap must

be turned on.

Check that there is film present.

Never lift the rolls of film without

help. To position the film: see

paragraph 5.3

The waste film removal system must be

properly aimed.

Adjustable by the technical

department.

Carry out a visual and manual check to

see that the plugs and other couplings are

properly fitted in the sockets.

Adjust the height of the conveyor belt to

suit the packaging.

Adjust the height using the

rotating knob under the belt. Also

use the lock nut.

Activate the required modules and

peripherals via the control panel.

Description in paragraph 4.

Ensure that the peripherals are ready and,

if necessary, are connected up.

See also manuals supplied with

peripherals.

Is the control panel displaying error

messages?

First correct the errors. For the

meaning of the error messages

see paragraph 1.1.

Loading...

Loading...