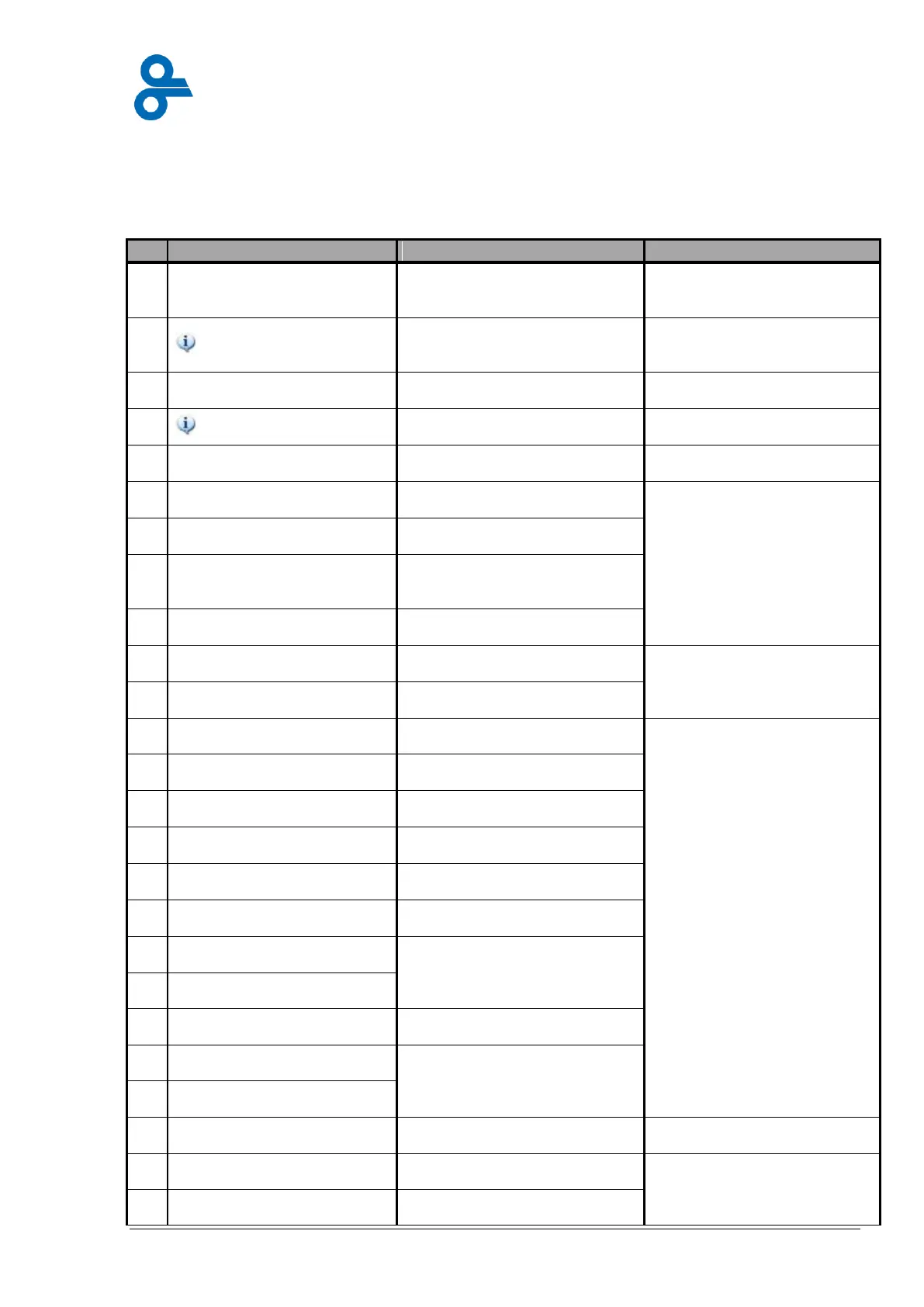

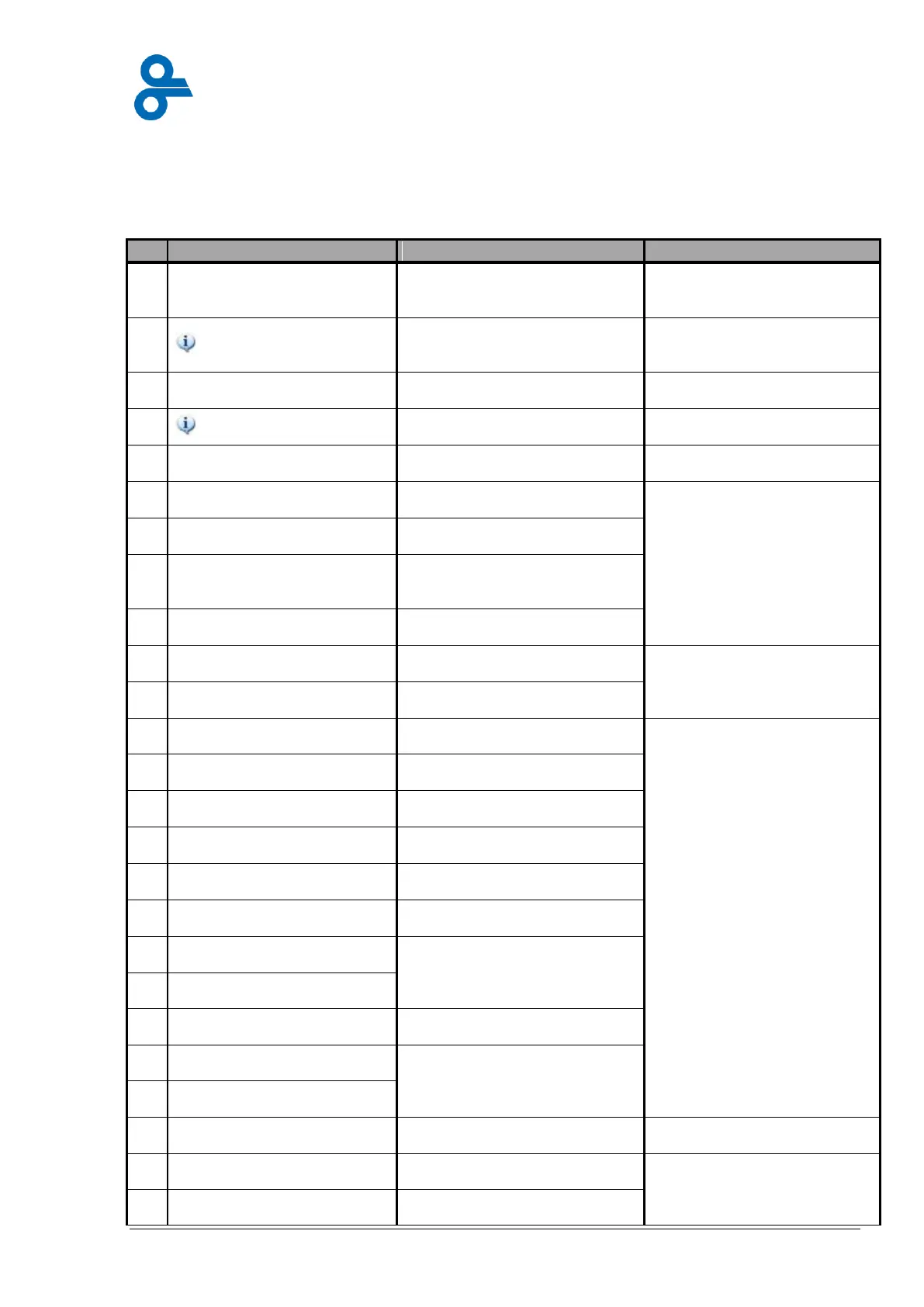

137

7.2 Overview of status lines

A machine failure causes an error message to be displayed on the touch screen status line.

Table 12 lists possible messages, their causes and the solutions.

Table 12 Overview of status lines

The emergency switch has been

pressed.

Start the machine according to

the procedure described in

paragraph 5.2.5.

The machine is switched into

night position.

This is normal. See paragraph

4.3.1.1 for turning off the night-

time status.

Form tool not in position

*1

The form tool is not properly

mounted on the lifting system.

Push bottom die in position

Servo system is resetting

Servo cross cutting is moving to

zero position.

Every time with new startup

Try to reset the servo system

Heater burnout Heating plate

The heating element in the

forming die top part is broken.

Call in the technical department.

Heater burnout Seal plate

The heating element in the seal

plate is broken.

Temperature outside limit

The sealing or forming unit has

exceeded the temperature

sensor’s range.

Temperature much too high

The temperature of the sealing or

forming units is too high.

The compressed air system is not

under pressure.

Check that the supply hose is

properly connected. If not, call in

the technical department.

The cooling water system is not

under pressure.

No central vacuum present

The machine has no vacuum.

Call in the technical department

The gas pressure for injecting gas

into the packs has failed.

No oil in lubrication system

The chain lubrication system has

run out of oil.

The motor inverter is showing a

failure.

The motor inverter is showing a

failure.

One of the motors has over-

heated.

Forming die not connected

Top die is not (properly)

connected to the electrical circuit.

One of the lifting systems is failing

to reach the lowest position.

The bottom die is not coming to its

upper position.

Bottom unwind is running out of

film.

Top unwind is running out of film.

Place new roll

Attach the film again to rewind

Film trim is broken (only rewind)

Loading...

Loading...