26

3 Description of the machine

The construction of the machine is based on modules. A rigid frame is used with suspension

buses on which the modules are hung. In consequence the machine can easily be adapted

to meet the customer’s specific requirements. In addition, only the frame is in contact with

the floor, which is an advantage as far as hygiene is concerned. Hygiene is taken into

account just as it is in the construction of the separate components. The main components

are described below as regards their technical characteristics and their functions.

3.1 Operation

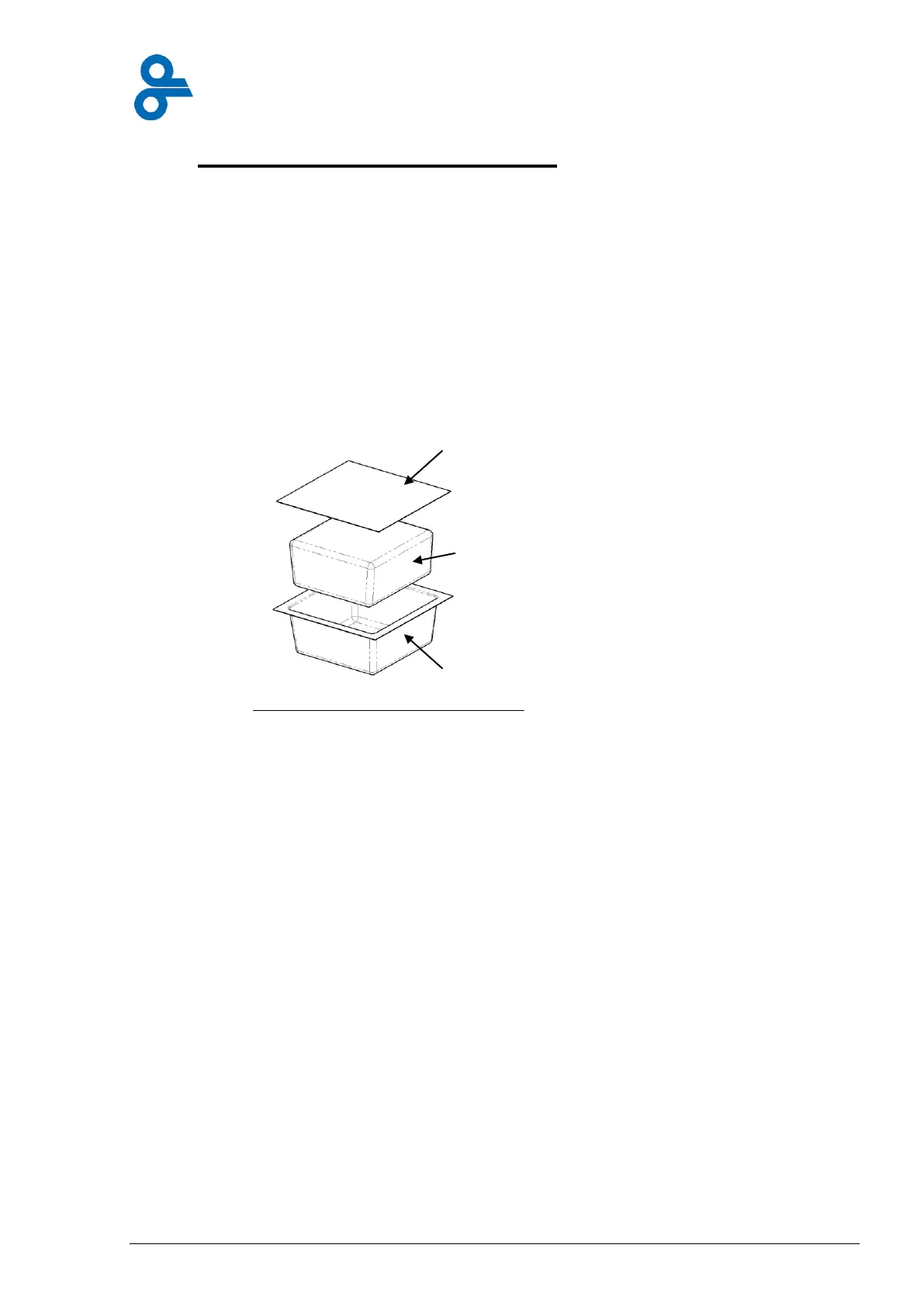

A packaging consists of upper and bottom film (see Figure 3.1).

The two sets of film are melted together along the edges to form a closed package.

The process starts when the film is fed in, with the bottom film being unrolled (see paragraph

3.3). The film is also stretched between the transport chains. The chain moves the film

forward in stages, known as stroke lengths or advances. The first process in the machine is

the forming stage (see paragraph 3.4). Here the film is first fixed between the top part of the

mould and the bottom part. The upper plate has a temperature of between 80-120

C and

176-248

F and ensures that the film can be shaped. At that point, compressed air forces the

film into the forming cavities in the bottom part. The bottom part is cooled and the packaging

shape releases as the lifting system lowers to its original position.

The film is now transported one stroke length further and a following stroke is made for the

forming die. The film that has just been shaped arrives at the loading area and is filled with

the product to be packaged (see paragraph 3.5). An operator or an external machine is

required for the filling process, during which the packaging is supported by product support

bars (see paragraph 3.5).

The top film is unwound from the film roll at the control cabinet (see paragraph 3.6).

Downstream of the loading area the top film is stretched over the product and is melted onto

the bottom film at the sealing station. When the bottom film moves forward another stroke

length, the top film is drawn along with it.

The packaged products are sealed closed in the sealing station (see paragraph 3.8) by the

bottom and top part of the sealing die.

Loading...

Loading...