13-4 Application Instructions Synchronous Motors MKD

19.05.2004 Version7.0 DOK-MOTOR*-MKD*******-PR07-EN-P

Option sealing air “sealing air: principle” connection

Sealing air connectors are available for MHD motors. They are attached

to the motor by simply replacing the motor flange socket cover. The

overpressure inside the motor prevents penetrating oils, aggressive

coolants, and the like from entering.

Note: When mounting the motor flange socket covers with sealing

air connector, ensure that the O-rings are properly seated.

The degree of protection required is ensured only with correct

assembly.

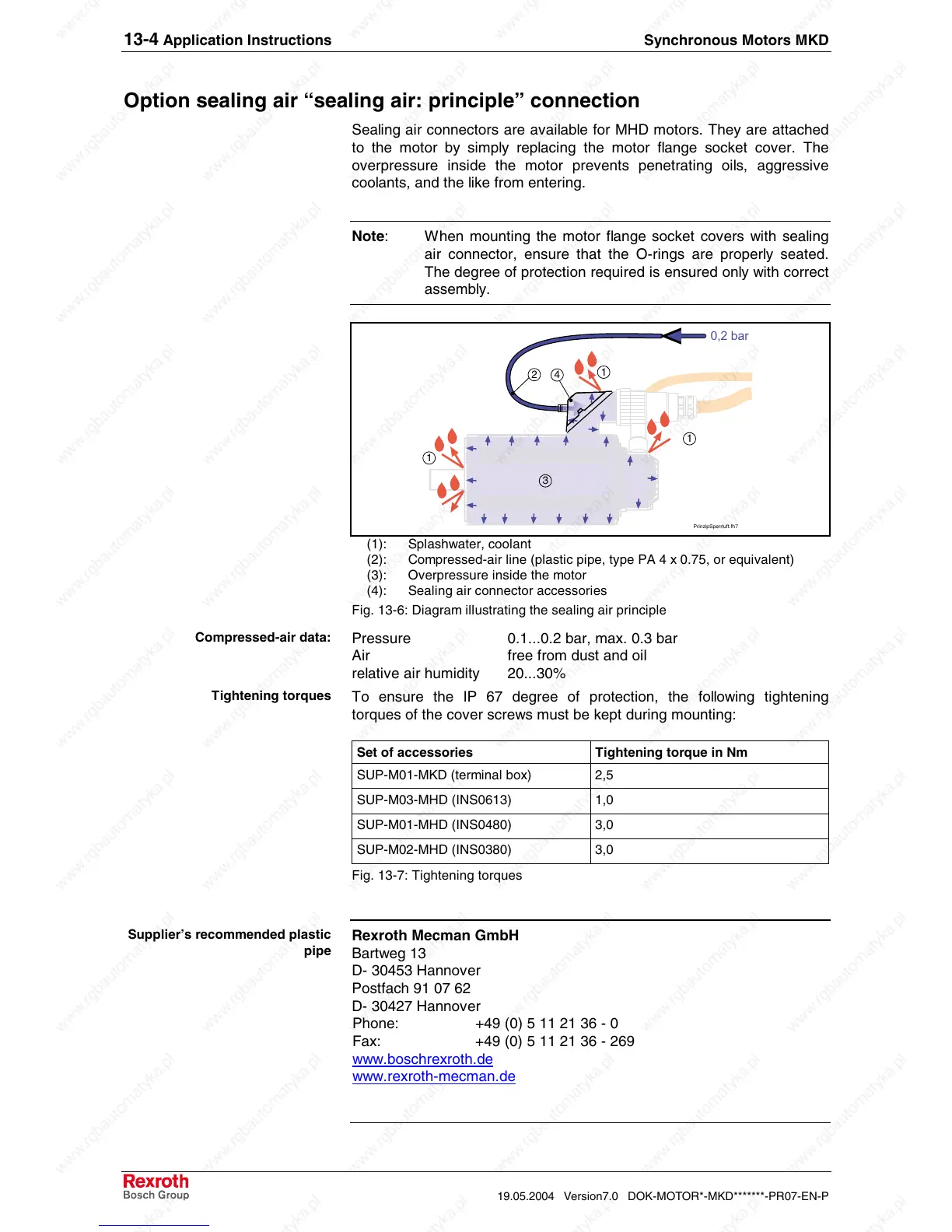

0,2 bar

2

3

1

1

1

4

PrinzipSperrluft.fh7

(1): Splashwater, coolant

(2): Compressed-air line (plastic pipe, type PA 4 x 0.75, or equivalent)

(3): Overpressure inside the motor

(4): Sealing air connector accessories

Fig. 13-6: Diagram illustrating the sealing air principle

Pressure 0.1...0.2 bar, max. 0.3 bar

Air free from dust and oil

relative air humidity 20...30%

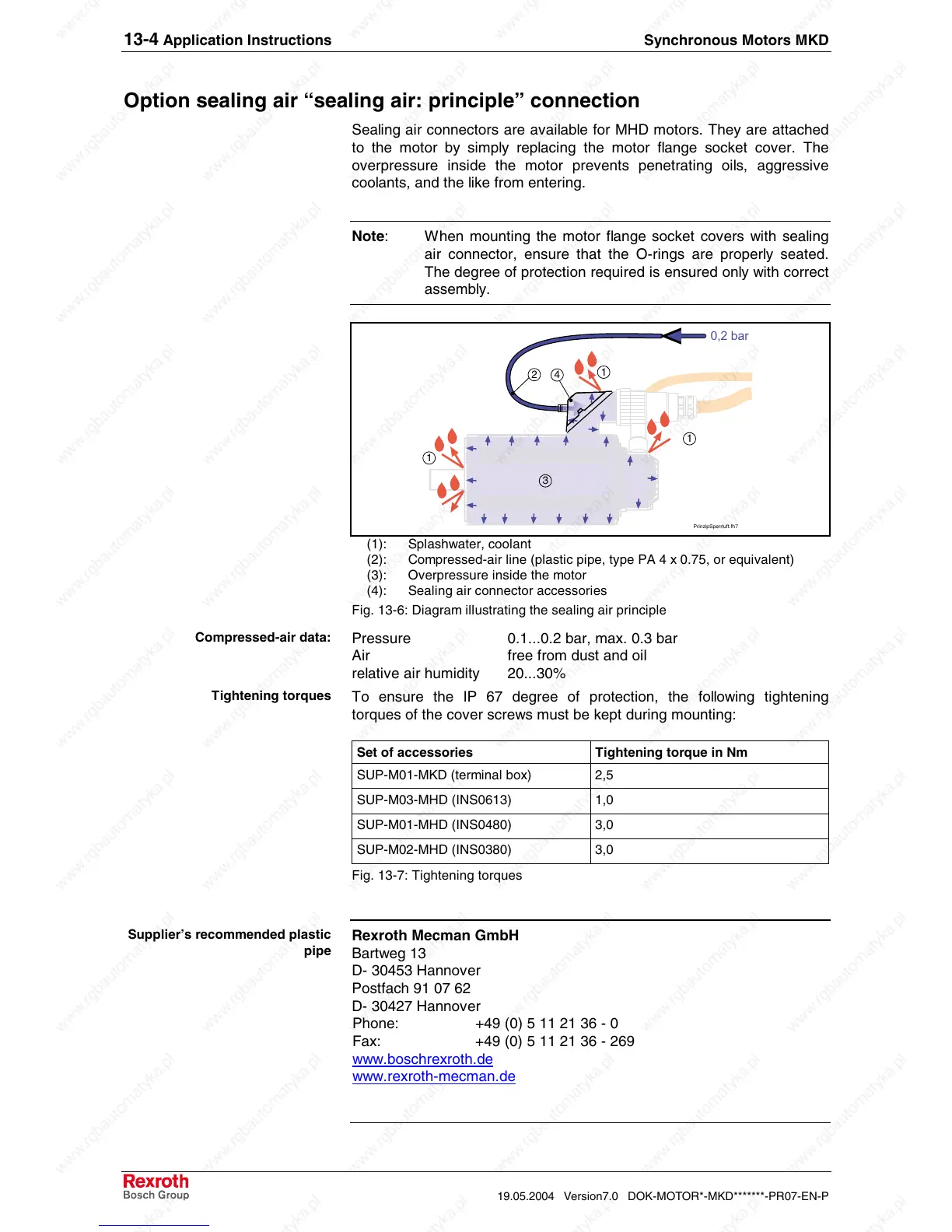

To ensure the IP 67 degree of protection, the following tightening

torques of the cover screws must be kept during mounting:

Set of accessories Tightening torque in Nm

SUP-M01-MKD (terminal box) 2,5

SUP-M03-MHD (INS0613) 1,0

SUP-M01-MHD (INS0480) 3,0

SUP-M02-MHD (INS0380) 3,0

Fig. 13-7: Tightening torques

Rexroth Mecman GmbH

Bartweg 13

D- 30453 Hannover

Postfach 91 07 62

D- 30427 Hannover

Phone: +49 (0) 5 11 21 36 - 0

Fax: +49 (0) 5 11 21 36 - 269

www.boschrexroth.de

www.rexroth-mecman.de

Compressed-air data:

Tightening torques

Supplier’s recommended plastic

pipe

Loading...

Loading...