13-14 Application Instructions Synchronous Motors MKD

19.05.2004 Version7.0 DOK-MOTOR*-MKD*******-PR07-EN-P

13.7 Motor Encoder

To control the motor speed and/or to position the motor, the drive

controller requires information on the current motor position.

To achieve this, the integrated encoder system (motor feedback) makes

the appropriate signals available to the drive controller. The drive

controllers are capable of transmitting the positional value thus

determined to a superordinate CNC or SPS.

The encoder electronics is equipped with a data memory where the

motor type name, the control loop parameters and the motor parameters

are filed.

These data are read by the digital intelligent drive controllers by Rexroth.

This ensures

• quick and easy startup,

• adjustment between the motor and the drive controller without the risk

of damage to the motor.

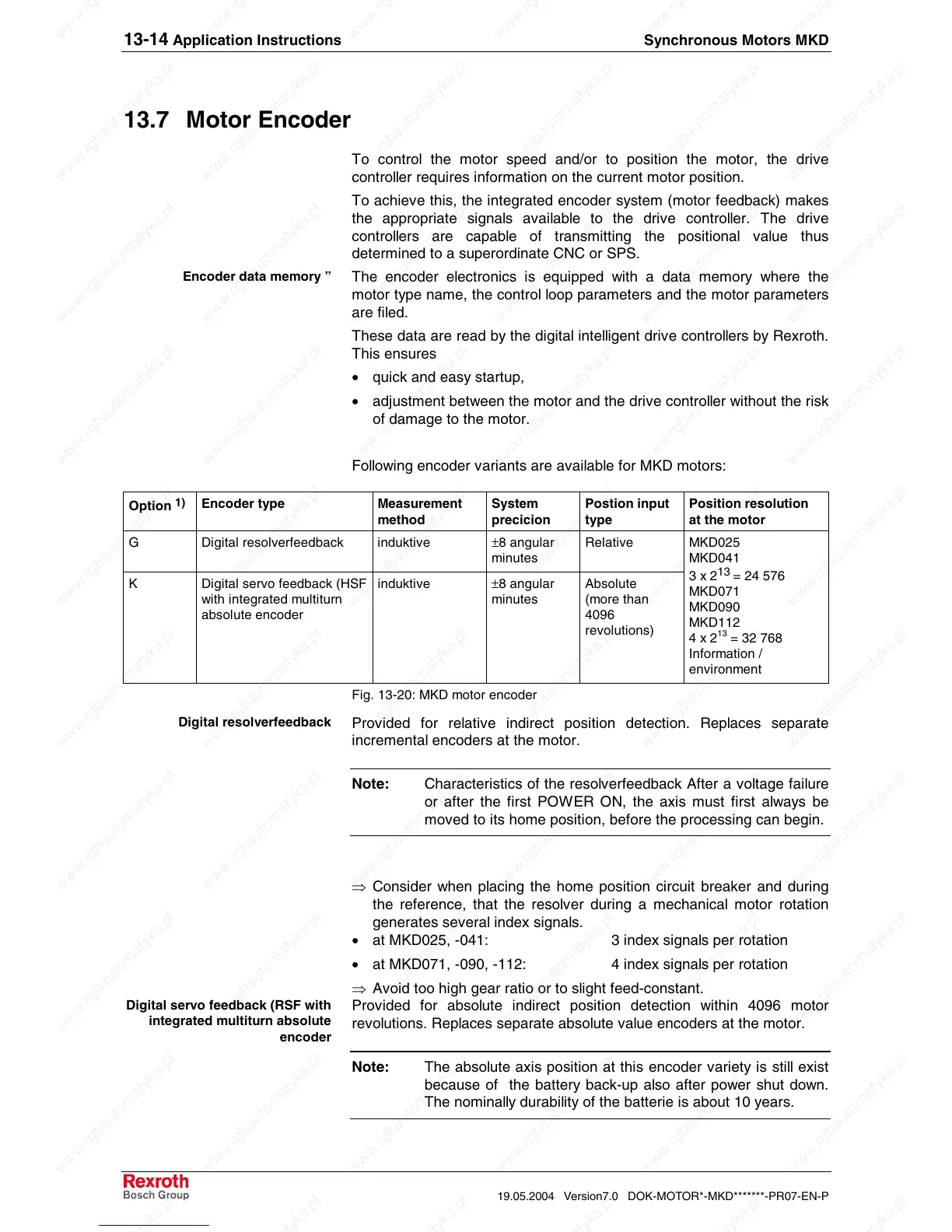

Following encoder variants are available for MKD motors:

Option

1)

Encoder type Measurement

method

System

precicion

Postion input

type

Position resolution

at the motor

G Digital resolverfeedback induktive

±8 angular

minutes

Relative

K Digital servo feedback (HSF

with integrated multiturn

absolute encoder

induktive

±8 angular

minutes

Absolute

(more than

4096

revolutions)

MKD025

MKD041

3 x 2

13

= 24 576

MKD071

MKD090

MKD112

4 x 2

13

= 32 768

Information /

environment

Fig. 13-20: MKD motor encoder

Provided for relative indirect position detection. Replaces separate

incremental encoders at the motor.

Note: Characteristics of the resolverfeedback After a voltage failure

or after the first POWER ON, the axis must first always be

moved to its home position, before the processing can begin.

⇒ Consider when placing the home position circuit breaker and during

the reference, that the resolver during a mechanical motor rotation

generates several index signals.

• at MKD025, -041: 3 index signals per rotation

• at MKD071, -090, -112: 4 index signals per rotation

⇒ Avoid too high gear ratio or to slight feed-constant.

Provided for absolute indirect position detection within 4096 motor

revolutions. Replaces separate absolute value encoders at the motor.

Note: The absolute axis position at this encoder variety is still exist

because of the battery back-up also after power shut down.

The nominally durability of the batterie is about 10 years.

Encoder data memory ”

Digital resolverfeedback

Digital servo feedback (RSF with

integrated multiturn absolute

encoder

Loading...

Loading...