Synchronous Motors MKD Application Instructions 13-11

DOK-MOTOR*-MKD*******-PR07-EN-P Version7.0 19.05.2004

Output Shaft with Shaft Sealing Ring

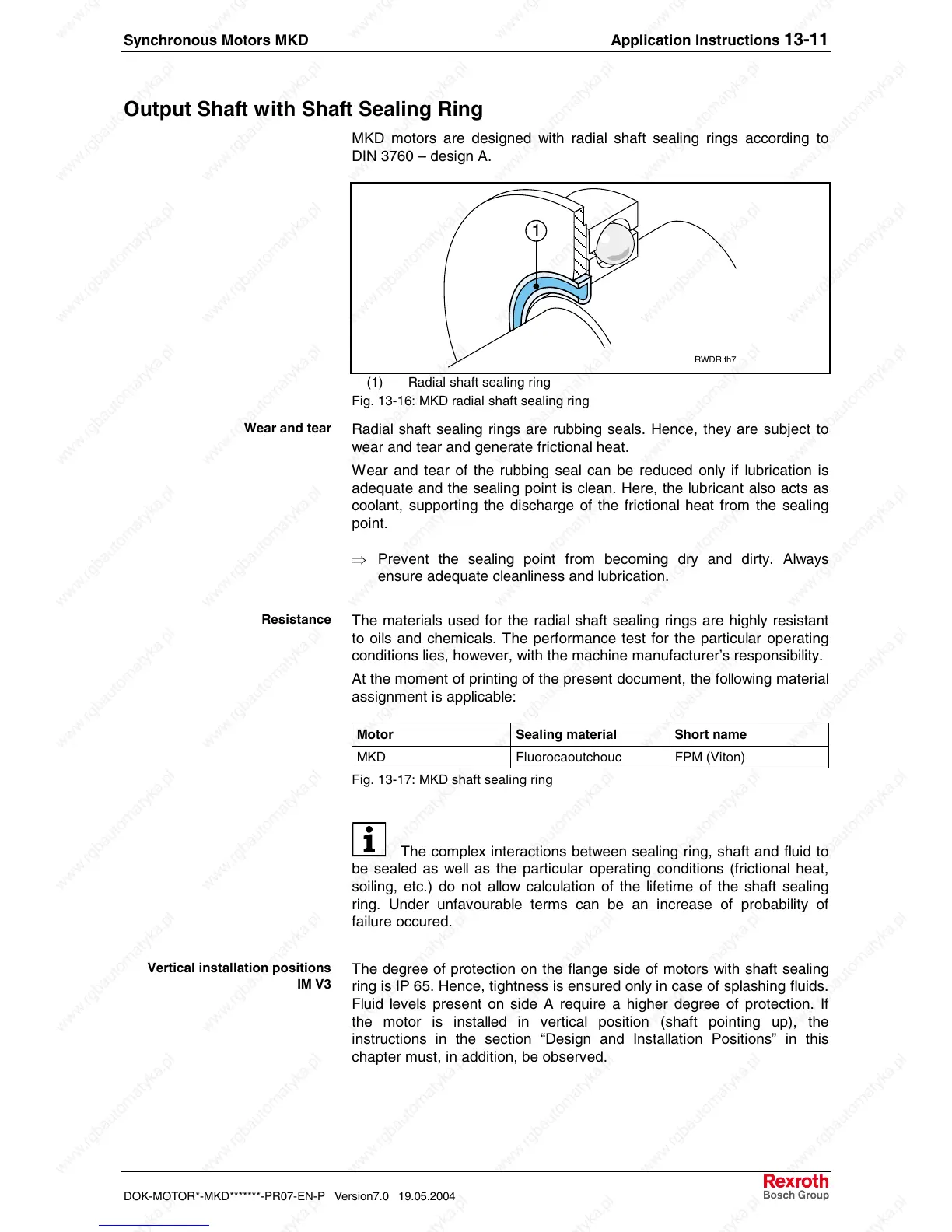

MKD motors are designed with radial shaft sealing rings according to

DIN 3760 – design A.

1

RWDR.fh7

(1) Radial shaft sealing ring

Fig. 13-16: MKD radial shaft sealing ring

Radial shaft sealing rings are rubbing seals. Hence, they are subject to

wear and tear and generate frictional heat.

Wear and tear of the rubbing seal can be reduced only if lubrication is

adequate and the sealing point is clean. Here, the lubricant also acts as

coolant, supporting the discharge of the frictional heat from the sealing

point.

⇒ Prevent the sealing point from becoming dry and dirty. Always

ensure adequate cleanliness and lubrication.

The materials used for the radial shaft sealing rings are highly resistant

to oils and chemicals. The performance test for the particular operating

conditions lies, however, with the machine manufacturer’s responsibility.

At the moment of printing of the present document, the following material

assignment is applicable:

Motor Sealing material Short name

MKD Fluorocaoutchouc FPM (Viton)

Fig. 13-17: MKD shaft sealing ring

The complex interactions between sealing ring, shaft and fluid to

be sealed as well as the particular operating conditions (frictional heat,

soiling, etc.) do not allow calculation of the lifetime of the shaft sealing

ring. Under unfavourable terms can be an increase of probability of

failure occured.

The degree of protection on the flange side of motors with shaft sealing

ring is IP 65. Hence, tightness is ensured only in case of splashing fluids.

Fluid levels present on side A require a higher degree of protection. If

the motor is installed in vertical position (shaft pointing up), the

instructions in the section “Design and Installation Positions” in this

chapter must, in addition, be observed.

Wear and tear

Resistance

Vertical installation positions

IM V3

Loading...

Loading...