13-10 Application Instructions Synchronous Motors MKD

19.05.2004 Version7.0 DOK-MOTOR*-MKD*******-PR07-EN-P

13.6 Output Shaft and Motor Bearing

Plain shaft

The standard design recommended for MKD motors provides a friction-

locked shaft-hub connection without play and excellent running

smoothness. Use clamping sets, clamping sleeves or clamping elements

to couple the machine elements to be driven.

Output shaft with key

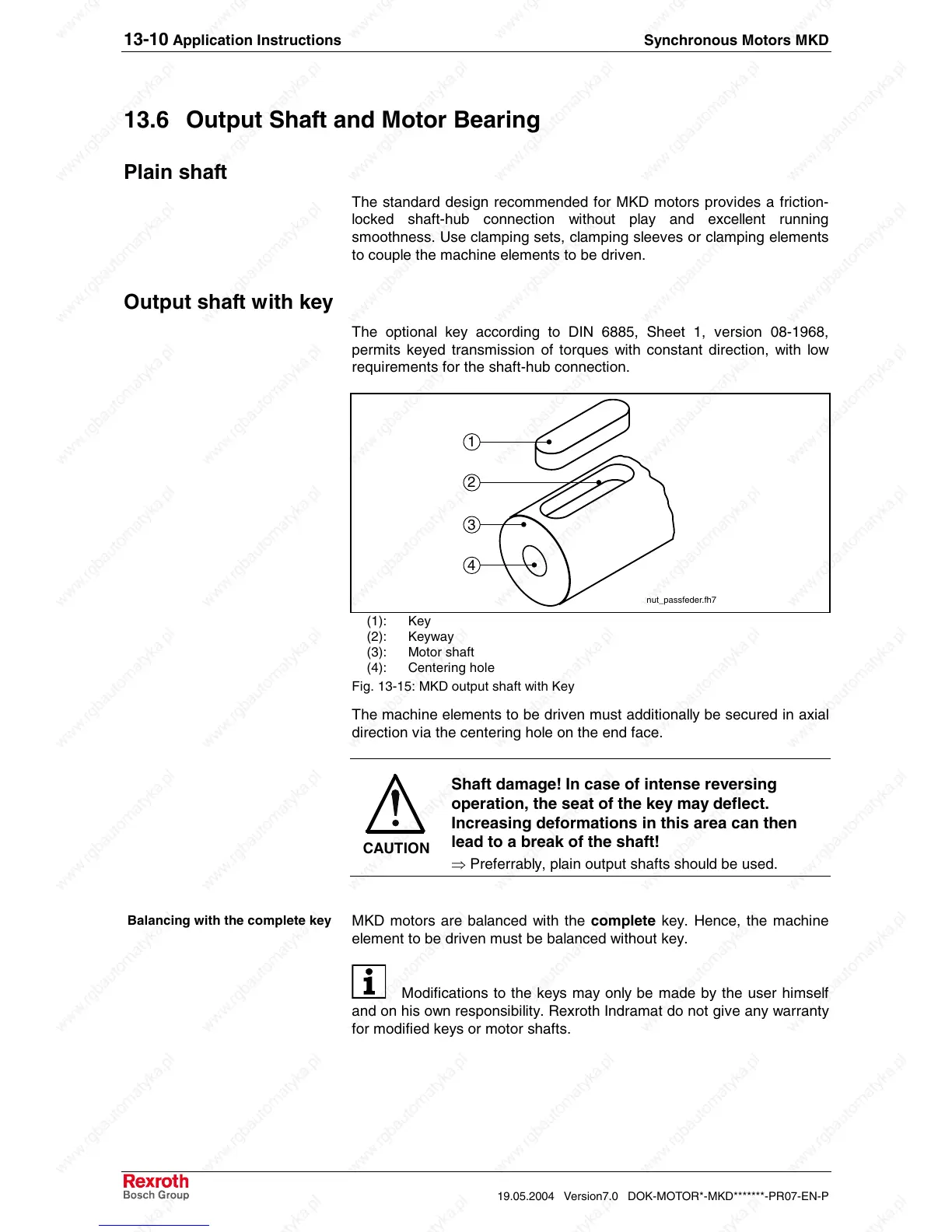

The optional key according to DIN 6885, Sheet 1, version 08-1968,

permits keyed transmission of torques with constant direction, with low

requirements for the shaft-hub connection.

1

2

3

4

nut_passfeder.fh7

(1): Key

(2): Keyway

(3): Motor shaft

(4): Centering hole

Fig. 13-15: MKD output shaft with Key

The machine elements to be driven must additionally be secured in axial

direction via the centering hole on the end face.

CAUTION

Shaft damage! In case of intense reversing

operation, the seat of the key may deflect.

Increasing deformations in this area can then

lead to a break of the shaft!

⇒ Preferrably, plain output shafts should be used.

MKD motors are balanced with the complete key. Hence, the machine

element to be driven must be balanced without key.

Modifications to the keys may only be made by the user himself

and on his own responsibility. Rexroth Indramat do not give any warranty

for modified keys or motor shafts.

Balancing with the complete key

Loading...

Loading...