13-6 Application Instructions Synchronous Motors MKD

19.05.2004 Version7.0 DOK-MOTOR*-MKD*******-PR07-EN-P

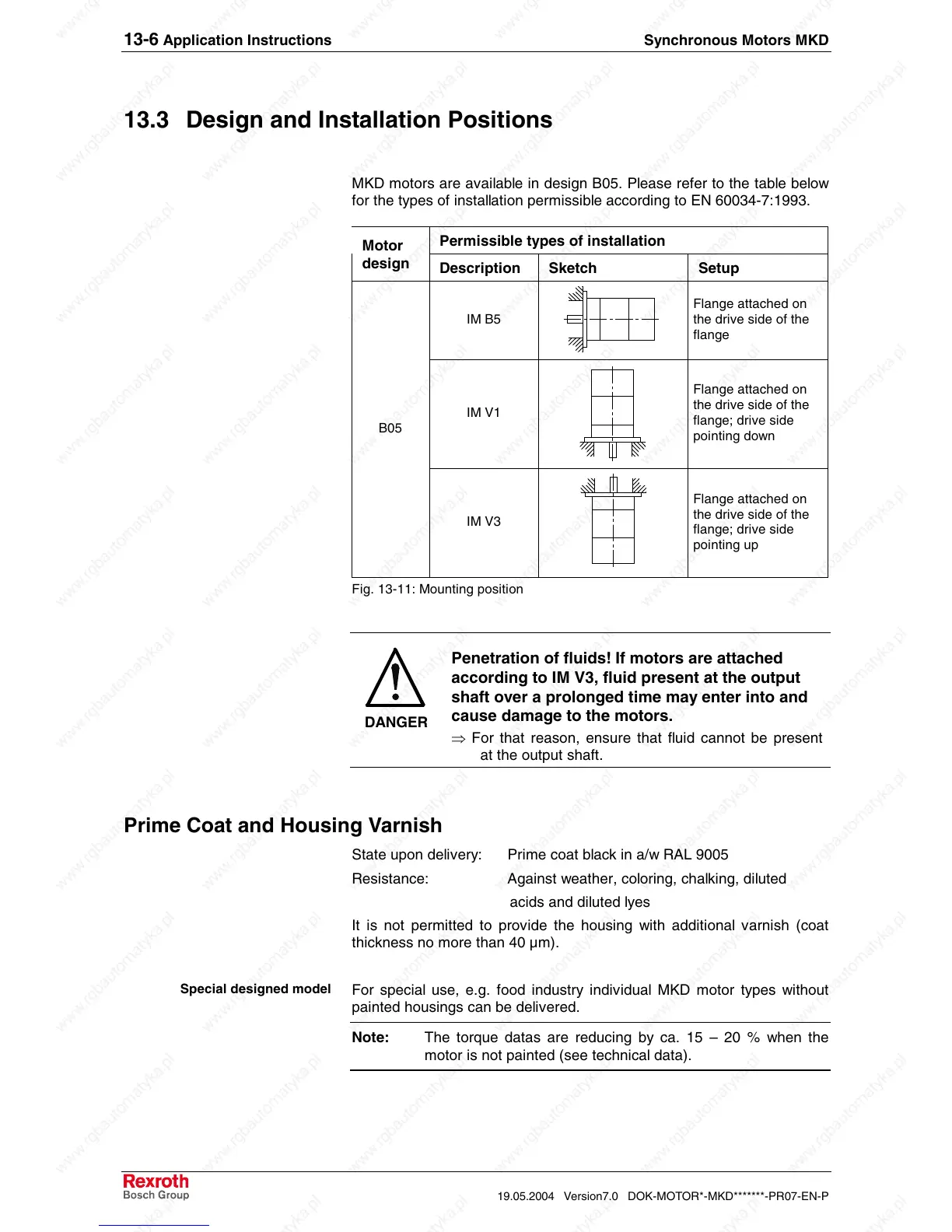

13.3 Design and Installation Positions

MKD motors are available in design B05. Please refer to the table below

for the types of installation permissible according to EN 60034-7:1993.

Permissible types of installation

Motor

design

Description Sketch Setup

IM B5

Flange attached on

the drive side of the

flange

IM V1

Flange attached on

the drive side of the

flange; drive side

pointing down

B05

IM V3

Flange attached on

the drive side of the

flange; drive side

pointing up

Fig. 13-11: Mounting position

DANGER

Penetration of fluids! If motors are attached

according to IM V3, fluid present at the output

shaft over a prolonged time may enter into and

cause damage to the motors.

⇒ For that reason, ensure that fluid cannot be present

at the output shaft.

Prime Coat and Housing Varnish

State upon delivery: Prime coat black in a/w RAL 9005

Resistance: Against weather, coloring, chalking, diluted

acids and diluted lyes

It is not permitted to provide the housing with additional varnish (coat

thickness no more than 40 µm).

For special use, e.g. food industry individual MKD motor types without

painted housings can be delivered.

Note: The torque datas are reducing by ca. 15 – 20 % when the

motor is not painted (see technical data).

Special designed model

Loading...

Loading...