Rockwell Automation Publication 750-TG100B-EN-P - June 2019 27

Chapter 2

Preventative Maintenance

This chapter provides information on preventative maintenance for components

that can affect the life and operational characteristics of PowerFlex® 750-Series

products with TotalFORCE® Control.

Recommended

Preventative Maintenance

Rockwell Automation recognizes that following a defined maintenance schedule

delivers the maximum product availability. By strictly following the maintenance

schedule of tasks that is provided for your operating environment, you can expect

the highest possible uptime. A maintenance schedule is provided for each of these

environments:

• Tab le 3

Recommended Maintenance Schedule for Normal Operation on

page 29

. Normal operation is defined as an environment where the

ambient temperature is less than or equal to 40 °C (104 °F).

• Tab le 4

Recommended Maintenance Schedule for High Temperature

Operation on page 33

. High temperature operation is defined as an

environment where the ambient temperature is above 41 °C (106 °F).

• Tab le 5

Recommended Maintenance Schedule for Harsh Environment

Operation on page 37

. Harsh environment is defined as a copper or silver

reactivity level greater than 1000 angstroms per 30 days exposure. No

condensation allowed. Maximum allowable humidity is 60% in the

presence of corrosive gases. See ISA-71.04-2013 for details on how to

measure reactivity levels on copper and silver test coupons.

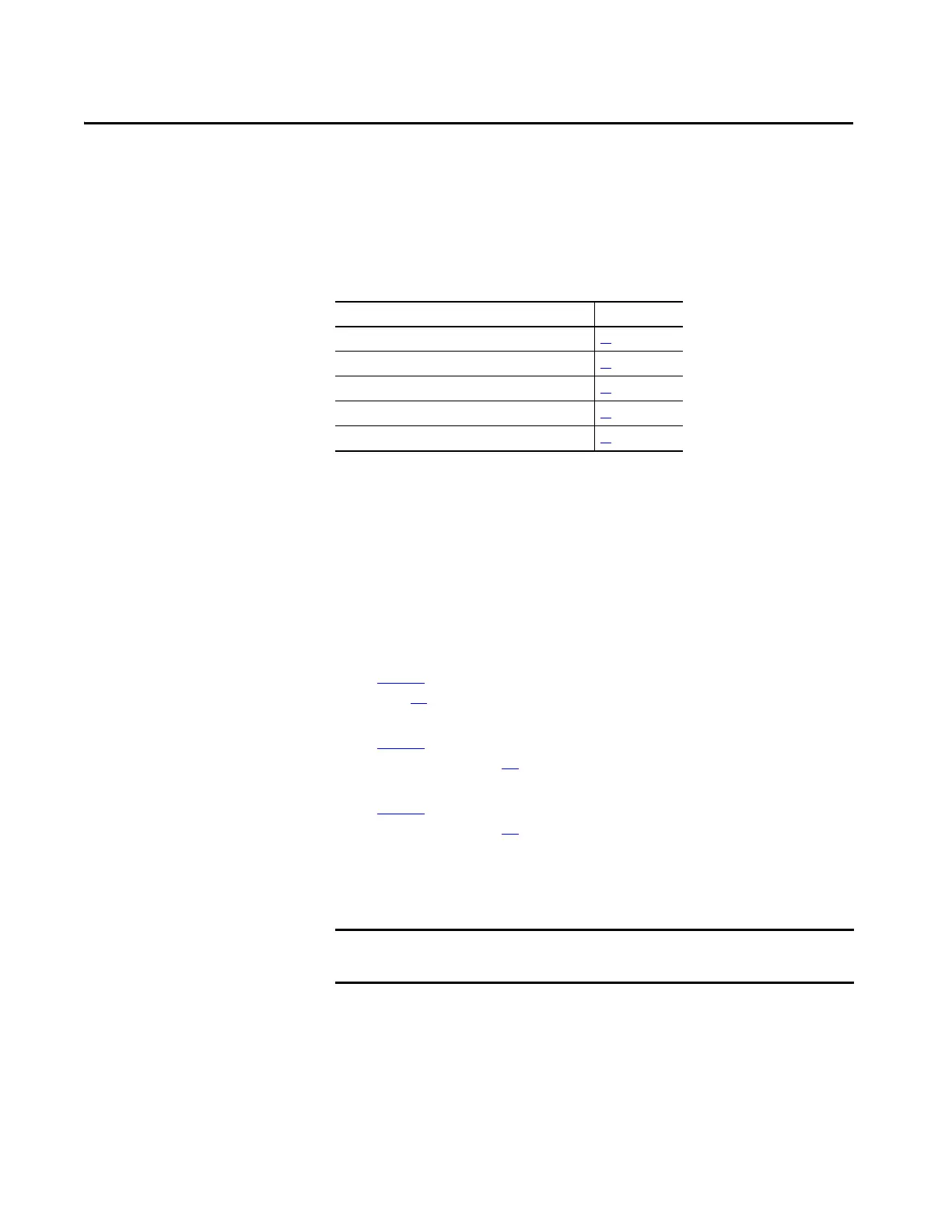

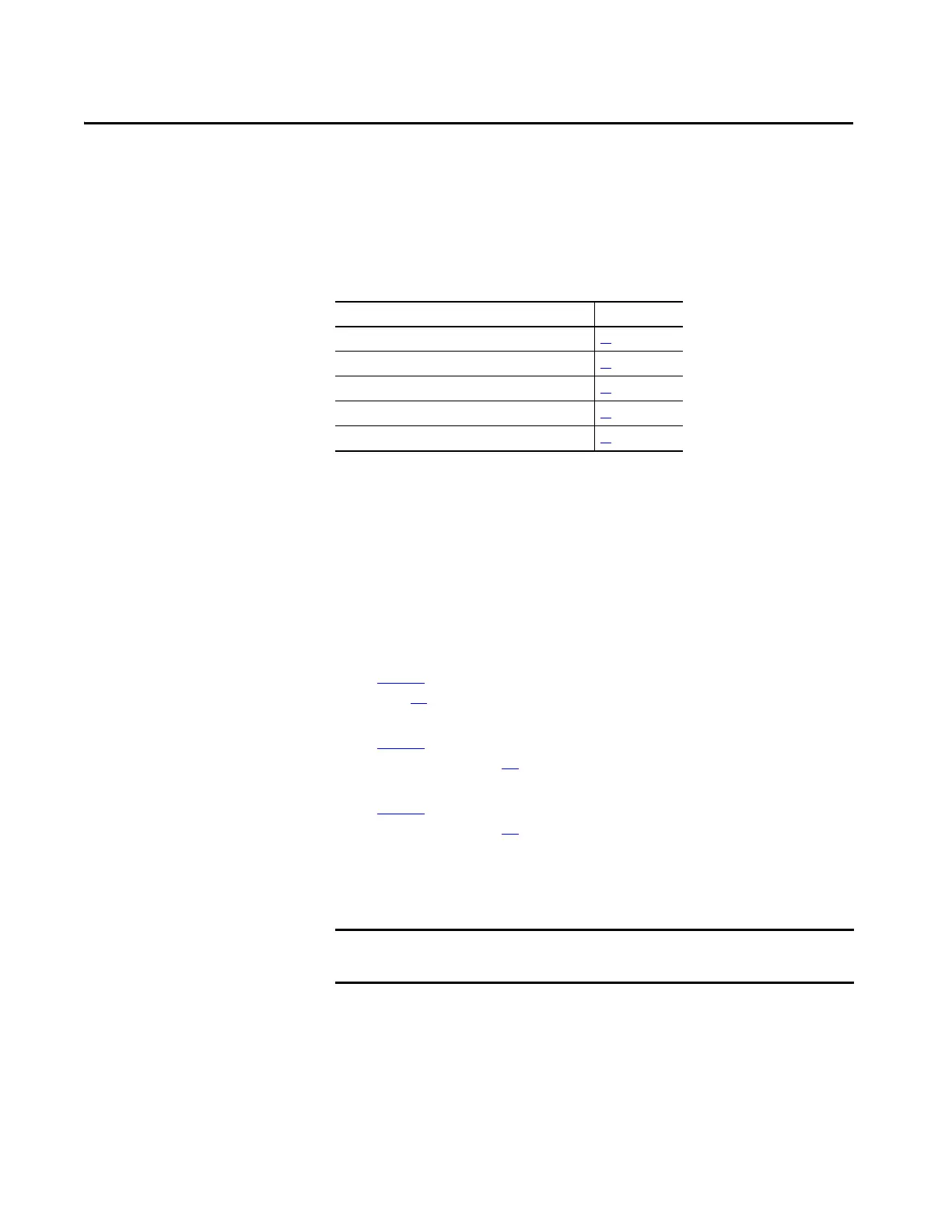

Topic Page

Recommended Preventative Maintenance 27

Predictive Maintenance 28

Schedule Codes Explanation 28

Shock Events 41

Maintenance of Industrial Control Equipment 42

IMPORTANT Duty cycle and load profile can greatly affect the reliability of PowerFlex

750-Series Products with TotalFORCE Control.

Loading...

Loading...