6-3

MODEL 2700 SECTION 6.0

TROUBLESHOOTING

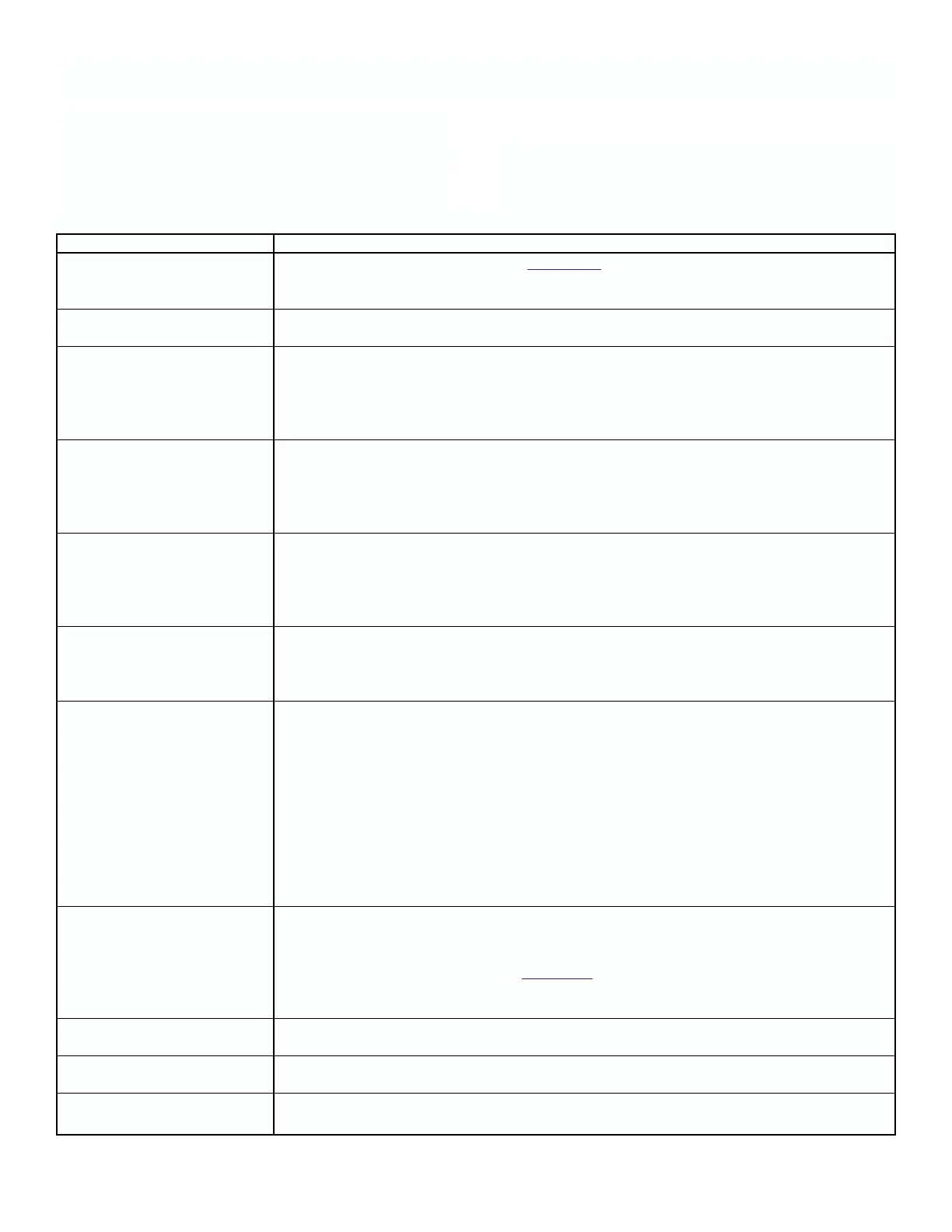

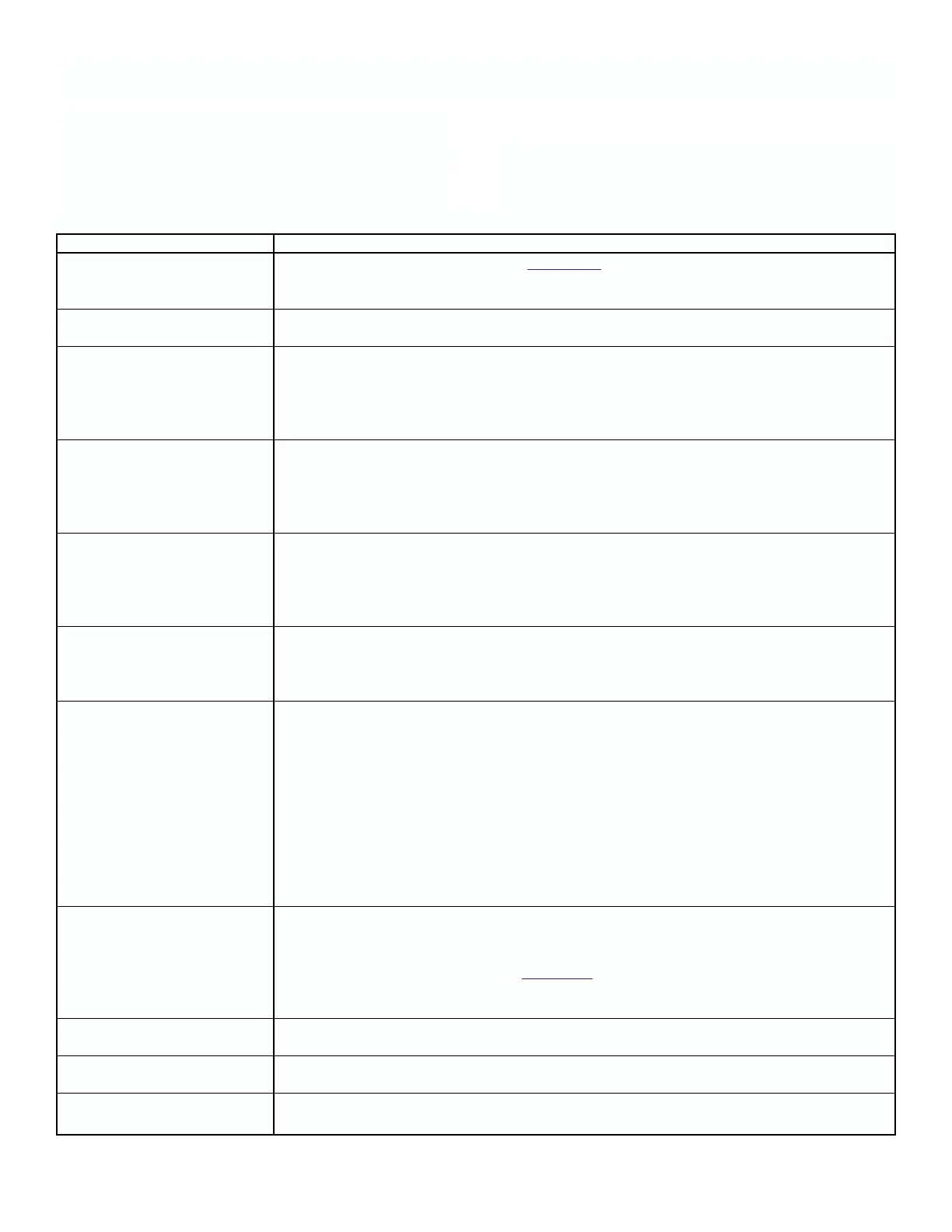

TABLE 6-2 Quick Troubleshooting Guide

SYMPTOM ACTION

Wrong temperature reading •

Perform a Single point calibration. (Section 3.0) If cannot calibrate, sensor is bad.

Suspected temperature • Adjust the analyzer temperature to that at the sensor.

compensation problem. Insure Calibration is not beyond ± 2 Deg C of raw value.

Display pixel missing, •

Remove sensor wiring; toggle power

Display not operating correctly.

• Replace display board.

Analyzer locks up; won’t respond.

• Remove sensor wiring; toggle power.

• Check Keypad cable connection. CAUTION: Cable terminal failure can result when

removed more than 5 times.

•

Replace electronics module.

• Toggle power.

Analyzer not responding to • Verify and clean ribbon cable connection on CPU board.

key presses.

Key press gives wrong • Check Keypad cable connection. CAUTION: Cable terminal failure can result

selection. when removed more than 5 times.

• Replace keyboard front panel assy.

Wrong or no current output. • Verify: Output is not being overloaded; remove load:

(Typical voltage across unloaded output is 14-15 Vdc) Current load is not more than 600

ohms. There are no breaks in connections. Wiring is correct. Operating ranges are

set correctly Whether or not Auto Ranging function is operative

• Replace electronics module.

No backlight on display, or • Verify power wiring.

indicators. • Toggle power

Blows Fuses. • Wrong fuse. Replace with P/N 9100178

• Replace electronics module.

Drifting or unstable Readings.

•

Air bubbles in process affecting reading. Remount sensor to decrease exposure

(also see suspected Temp. to air bubbles.

Comp. problem) • Check programming of Liquid Type.

• Check programming of units of measure.

• Incorrect sensor cell constant for application.

• Verify process temperature is stable.

• Electrical or grounding interference.

• Verify sensor works in a standard solution outside of the process.

• Verify nearby water pumps motors are properly grounded.

• Verify that sensor shield never touches an Earth Ground.

• Run sensor cable through grounded metal conduit to reduce RFI effects.

Inaccurate or erroneous • Wrong sensor for measurement range.

readings. • Verify that the cell constant is correct for the measurement range

(conductivity).

• Verify Liquid Type selected (See Figure 4-2) (conductivity).

• Place sensor in known solution and check reading. If incorrect, sensor needs to be

replaced.

pH reading won’t change in

• Clean the electrode, check for cracks in the bulb.Replace electrode if

different buffers cracked. Check impedance. If zero, replace glass electrode.

pH sensor has sluggish

• Check the electrode; if still sluggish soak in 10% HCl for 1 hr.

response. Replace electrode if not rejuvenated by the HCl soak.

Will calibrate in buffers but

• Process problem or possible ground loop. Make sure that the shield wires do

not in process. NOT touch grounded metal. Disconnect output and relay connections.

6.3 TROUBLESHOOTING GUIDE

Table 6-2 lists typical symptoms that may be

encountered and suggested actions.

These are not meant to be all inclusive, but to provide a

starting point for some of the more common problems

that may occur.

Loading...

Loading...