If your actuator cannot be installed

immediately store it in a dry place until

you are ready to connect incoming

cables.

If the actuator has to be installed but

cannot be cabled it is recommended

that the plastic transit cable entry plugs

are replaced with metal plugs which are

sealed with PTFE tape.

The Rotork double-sealed construction

will preserve internal electrical

components perfectly if left

undisturbed.

It is not necessary to remove any

electrical compartment covers in order

to commission the IQT actuator.

Rotork cannot accept responsibility for

deterioration caused on-site once the

covers are removed.

Every Rotork actuator has been fully

tested before leaving the factory to

give years of trouble free operation,

providing it is correctly commissioned,

installed and sealed.

3.1 Operating by Hand

WARNING

With respect to handwheel

operation of Rotork electric

actuators, under no circumstances

should any additional lever

device such as a wheel-key

or wrench be applied to the

handwheel in order to develop

more force when closing or

opening the valve as this may

cause damage to the valve and/or

actuator or may cause the valve

to become stuck in the seated/

backseated position.

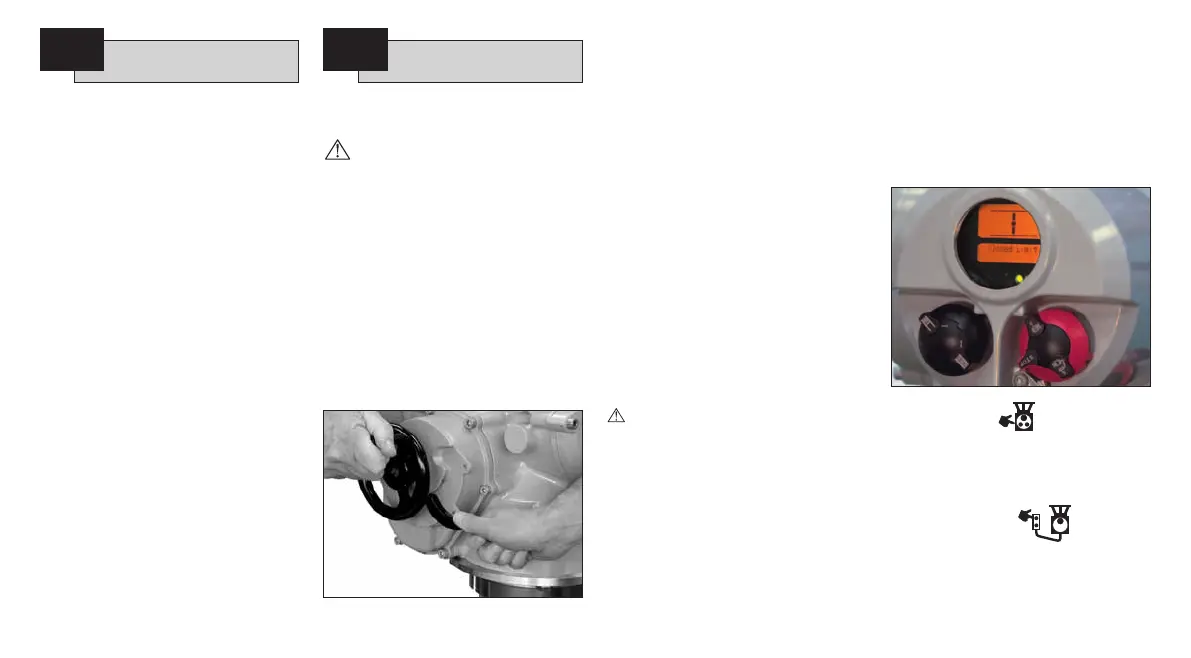

Fig. 3

To engage handwheel drive, turn

the Hand/Auto lever clockwise whilst

turning the handwheel, see Fig 3. The

lever can now be released upon which

it will return to its original position. The

handwheel will remain engaged until

the actuator is operated electrically

when it will automatically disengage

and return to motor drive. If required

the Hand/Auto lever can be locked in

either position using a padlock with a

6.5mm hasp.

3.2 Operating Electrically

Check that power supply voltage agrees

with that stamped on the actuator

nameplate. Switch on power supply. It

is not necessary to check phase rotation.

Do not operate the actuator

electrically without first checking,

using the infra-red Setting Tool,

that at least the Primary Settings

have been made

(refer to Section

8 page 17).

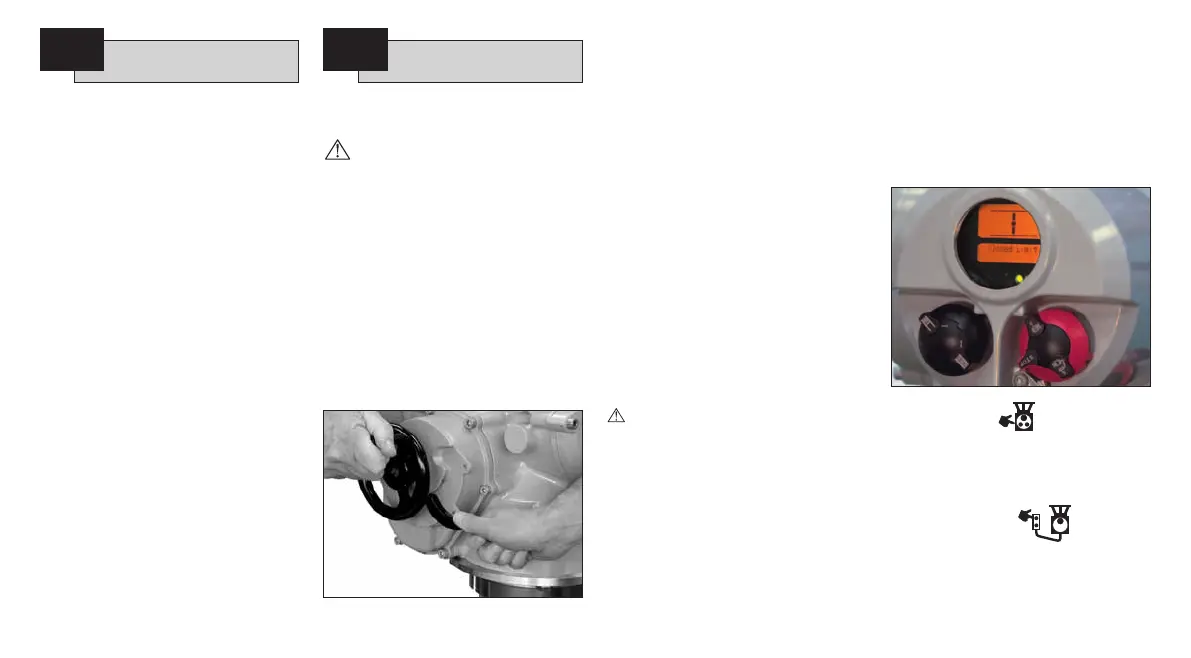

Selecting Local/Stop/Remote

Operation

The red selector enables either Local or

Remote control, lockable in each position

using a padlock with a 6.5mm hasp.

When the selector is locked in the Local

or Remote positions the Stop facility is still

available. The selector can also be locked

in the Stop position to prevent electrical

operation by Local or Remote control.

Fig. 3.1

Local Control

With the red selector positioned at

Local (anti-clockwise) the adjacent black

knob can be turned to select Open or

Close. To Stop, turn red knob clockwise.

Remote Control

Rotate the red selector to the Remote

position (clockwise), this gives remote

control only for Open and Close but

local Stop can still be used by turning

the red knob anti-clockwise.

3

3

Storage

2

Operating your

IQT Actuator

Loading...

Loading...