English

12

67

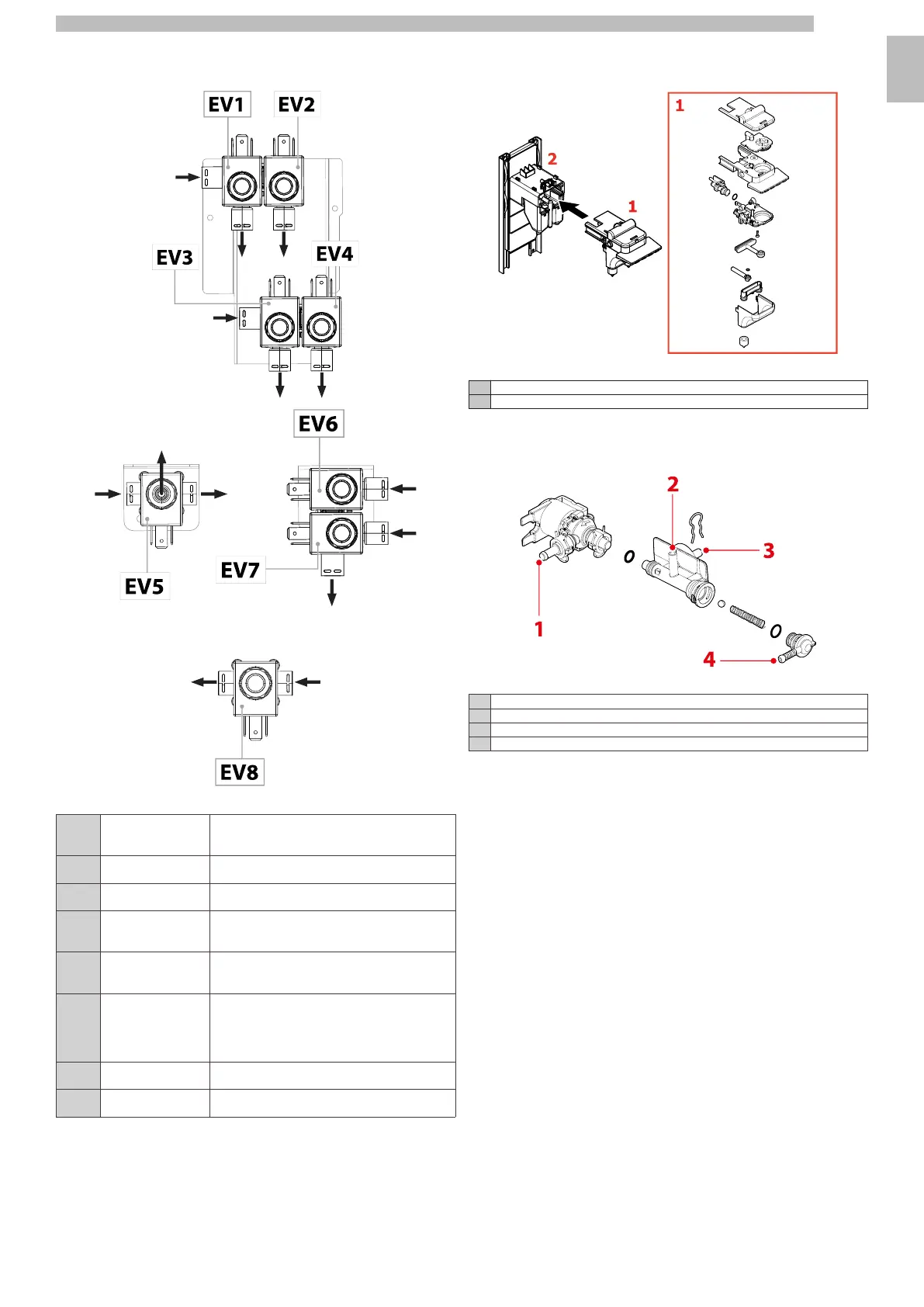

12.2Emulsifier valve

12

(*only

versions

M2

and

M1).

12121212121212

(*only

versions

B2

and

B1).

121212121212

EV1EV steamPuts the steam circuit in communication with the

cappuccino maker.

The steam reaches the steam injector directly.

EV2EV pressure dischargeSteam vents into the tray which lowers the pressure in

the boiler and empties it if necessary.

EV3EV hot waterIntercepts water from the coffee circuit to dispense hot

water directly into the cup.

EV4EV rinsingIntercepts hot water from the coffee circuit and sends

it to the air and milk suction circuit of the cappuccino

maker to dry it.

EV5EV air dischargeMakes it possible to intercept the "milk suction branch"

and "air suction branch" circuits: serves as diverter

during rinse phase with air/water.

EV6EV air flow

+

Compressor

Inserts compressed air into the air suction circuit to:

- avoid demijohn effect milk jug - cup at end dispensing.

- empty internal circuit of the rinse water.

EV7EV of air inputSolenoid valve for the management of the frothed and

non frothed milk.

EV8EV hot waterIntercepts water from the coffee circuit to dispense hot

water directly into the cup.

121212

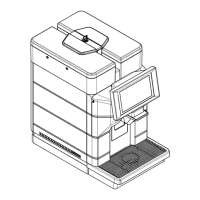

12.3Cappuccinatore unit

12

(*only

versions

M2

and

M1).

121212121212

1Cappuccinatore unit

2Dispensing spout unit

12121212

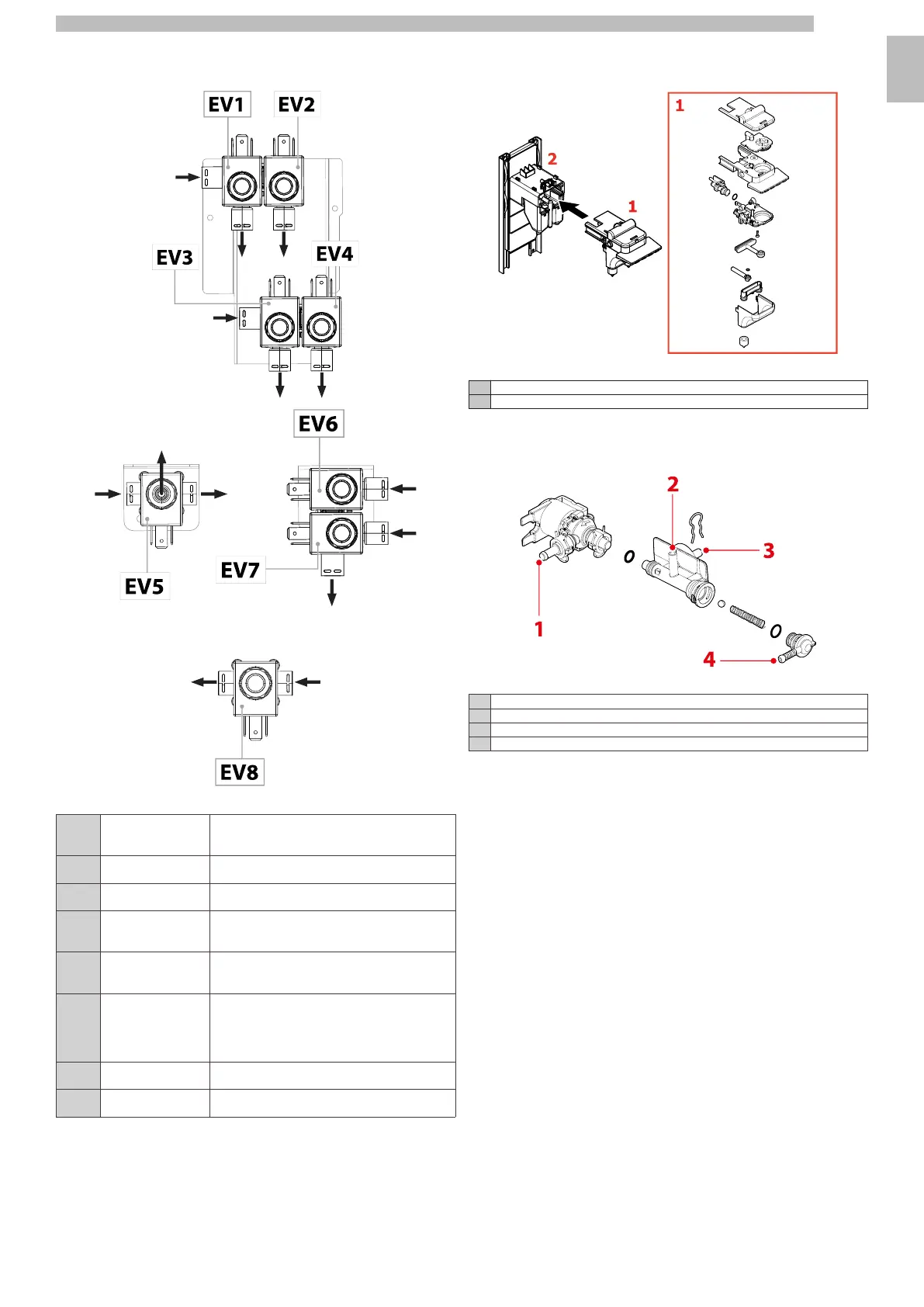

12.4Solenoid pilot valve

1212121212

1Discharge of the liquids recovery tank (normally open).

2Drip prevention of coffee in output.

3Coffee input.

4Coffee output.

12121212

12.5Single micro. gearmotor

12

Power

on

12

When the machine is switched on the gearmotor positions itself as follows:

12

•

It presses micro 1 (see next section)

12

•

The gearmotor changes the rotation direction and moves upward by ca. 1-2 mm

12

•

Theboilerbeginstoheatthewaterforca.45seconds,absorbingfullheating

powertoreachtheoptimaltemperature.Afterthisthetemperatureismaintained

constant.

1212

Coffee

Cycle

12

1. The coffee grinder begins grinding (managed by the dosing unit micro)

12

2. Dosing unit open

12

3. The gearmotor (brew group) moves to dispensing position

12

4. Preliminary dispensing phase (brief pump activation, brief pause)

12

5.Productdispensing(pumpoperationtimeisdeterminedbythequantityof

product dispensed)

12

6. The gearmotor moves to off position - coffee grounds are automatically expelled.

1212

Loading...

Loading...