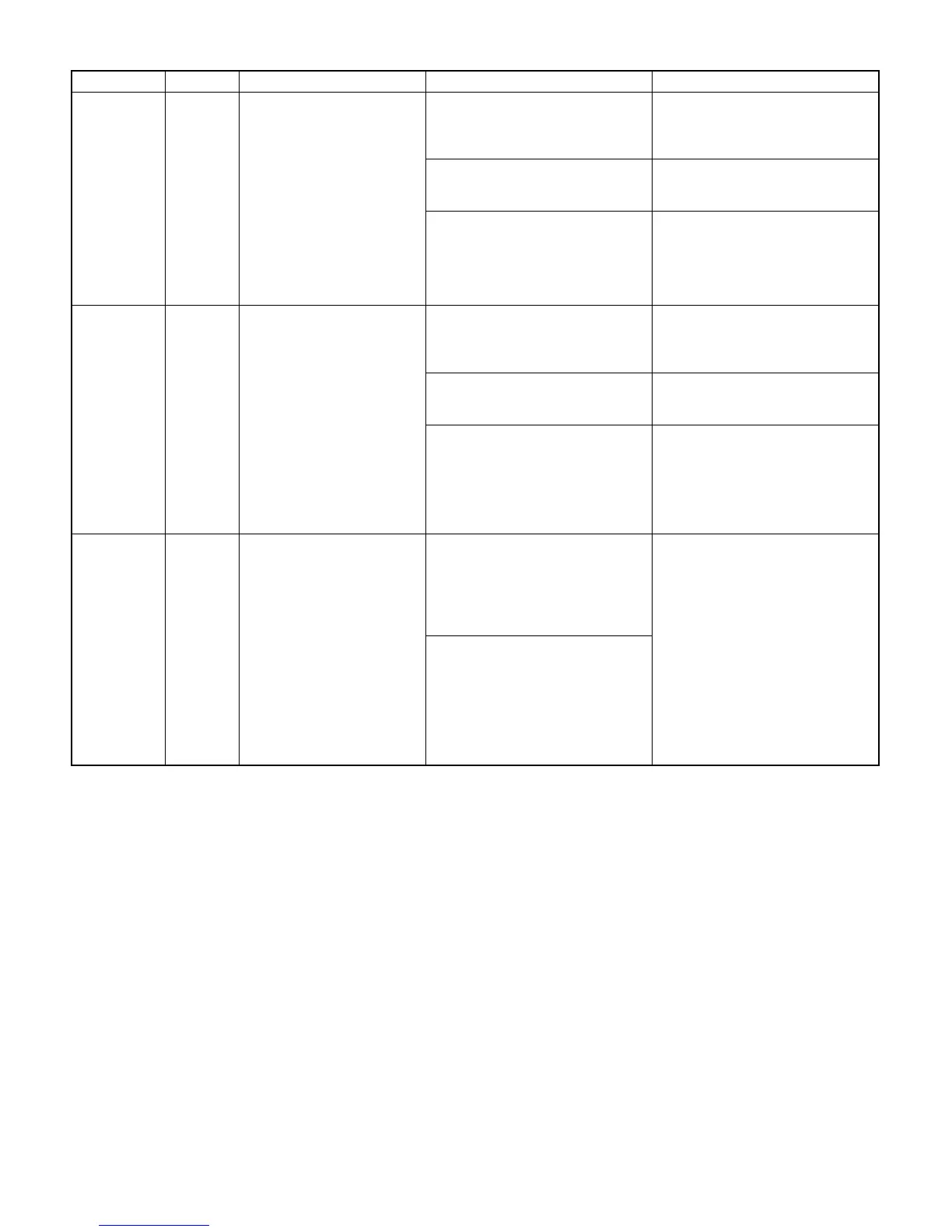

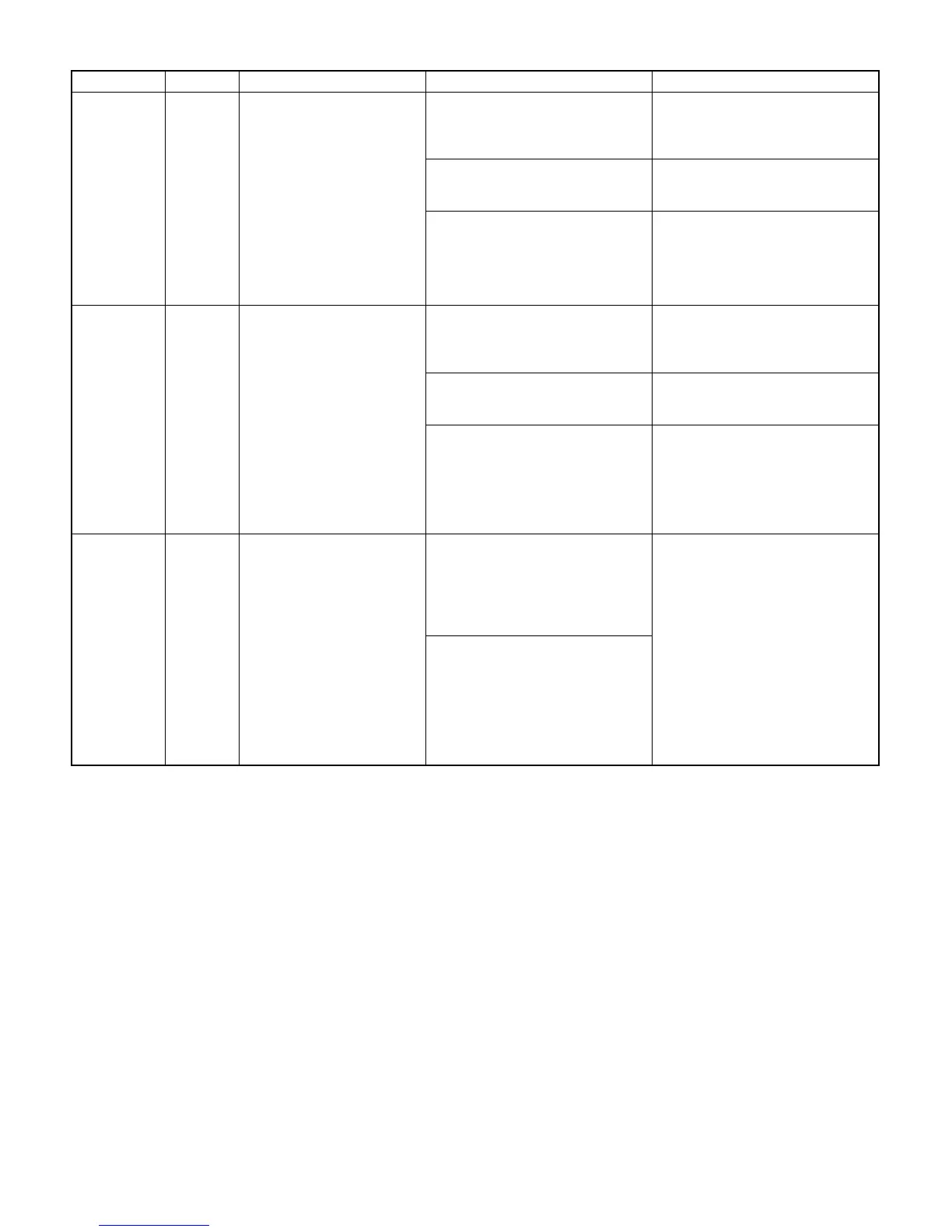

(Trouble codes and countermeasures)

Trouble code Sub code Content Possible cause Countermeasure

F2 31 Image exposure sensor error

Photoconductor surface

reflection detection error

Copier operation halt when

sensing

Dirt on the image density sensor (ID) Clean the image density sensor and

its peripheral. Use soft cloth

immersed in water or alcohol to clean

the sensor surface.

Dirt on the drum surface by

incomplete cleaning

Check the cleaning blade and the

photoconductor drum surface and

replace them if necessary.

Image density sensor (ID) sensing

level is not adjusted.

Execute simulation No. 44-3. (Set to

204±10 with VR2.)

Image density sensor (ID) PWB

trouble

* Process control VR PWB trouble

F2 32 Drum mark sensor trouble

Surface level and drum mark

sensing abnormality

Copier operation halt when

sensing.

Dirt on the drum mark sensor (DM) Clean the drum mark sensor (DM)

and its peripheral. Use soft cloth

immersed in water or alcohol to clean

the sensor surface.

Dirt on the drum surface by incomplete

cleaning

Check the cleaning blade and the

photoconductor drum surface, and

replace them if necessary.

Drum mark sensor (DM) sensing level

is not adjusted.

Improper drum (drum without mark)

Execute simulation No. 44-2. (Set to

204±10 with VR1.)

* Drum mark sensor (DM) PWB

trouble

* Process control VR PWB trouble

F2 35 Process control operation

failure

When 1 or 2 is detected,

process control is fixed to the

reference condition.

In case of an accidental

trouble caused by the change

in environments (temperature,

humidity), if the inside state of

the machine recovers, then

the trouble will be cleared.

1 Image density is too high to be

corrected. (When executing

simulation No. 44-6)

Developer/toner density changes

greatly.

Humidity and temperature is low.

Check the developer unit.

Visually check the pressure contact

and the lock state.

• Check the high voltage output.

Simulation No. 44-11.

2 Image density is too low to be

corrected.

(When executing simulation No.

44-6)

Developer/toner density changes

greatly.

Humidity and temperature change

greatly.

NORMAL: –860V

PATCH: –610V

Simulation No. 8-1

DV BIAS: –300V

• Developer stirring

Simulation No. 25-1.

Replace the developer.

7 – 24

Loading...

Loading...