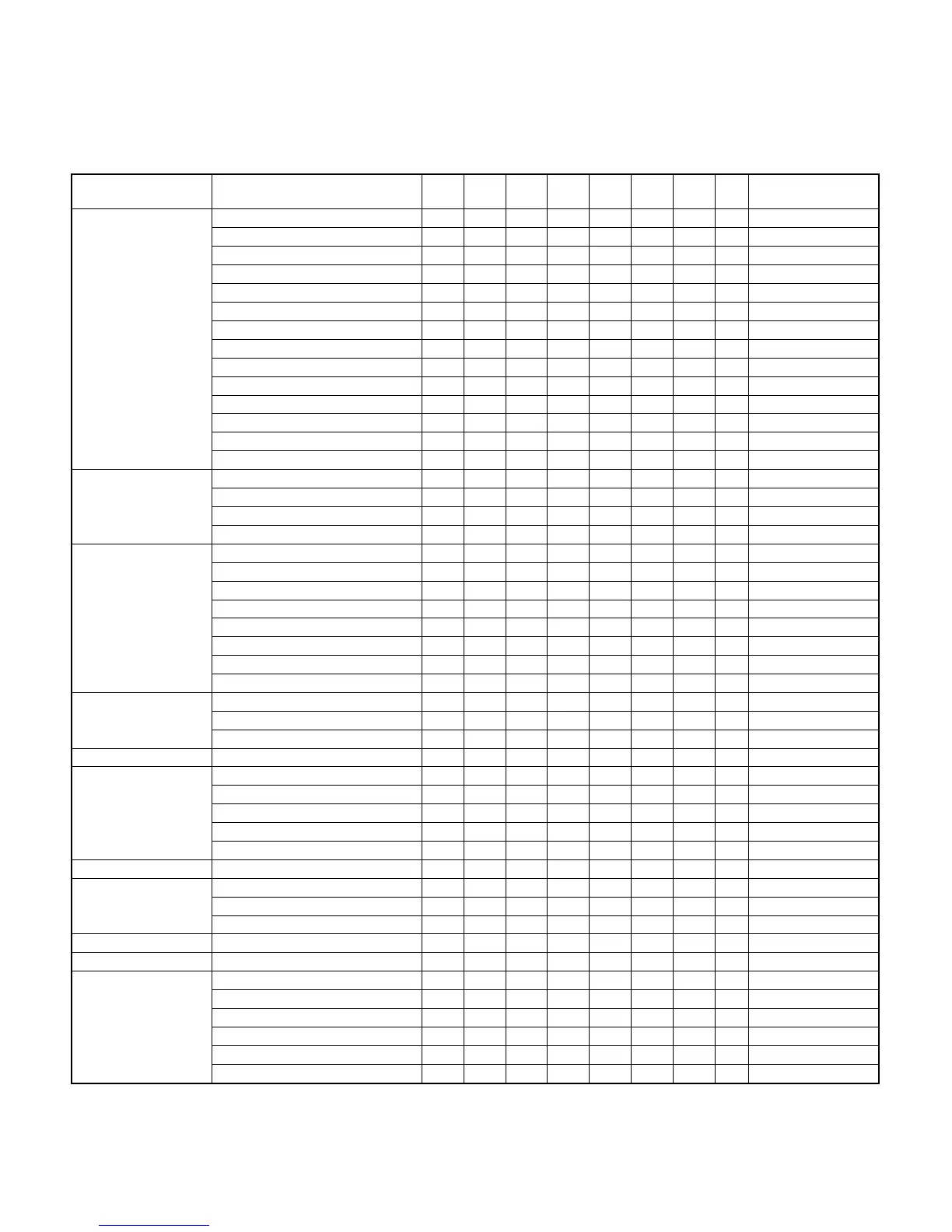

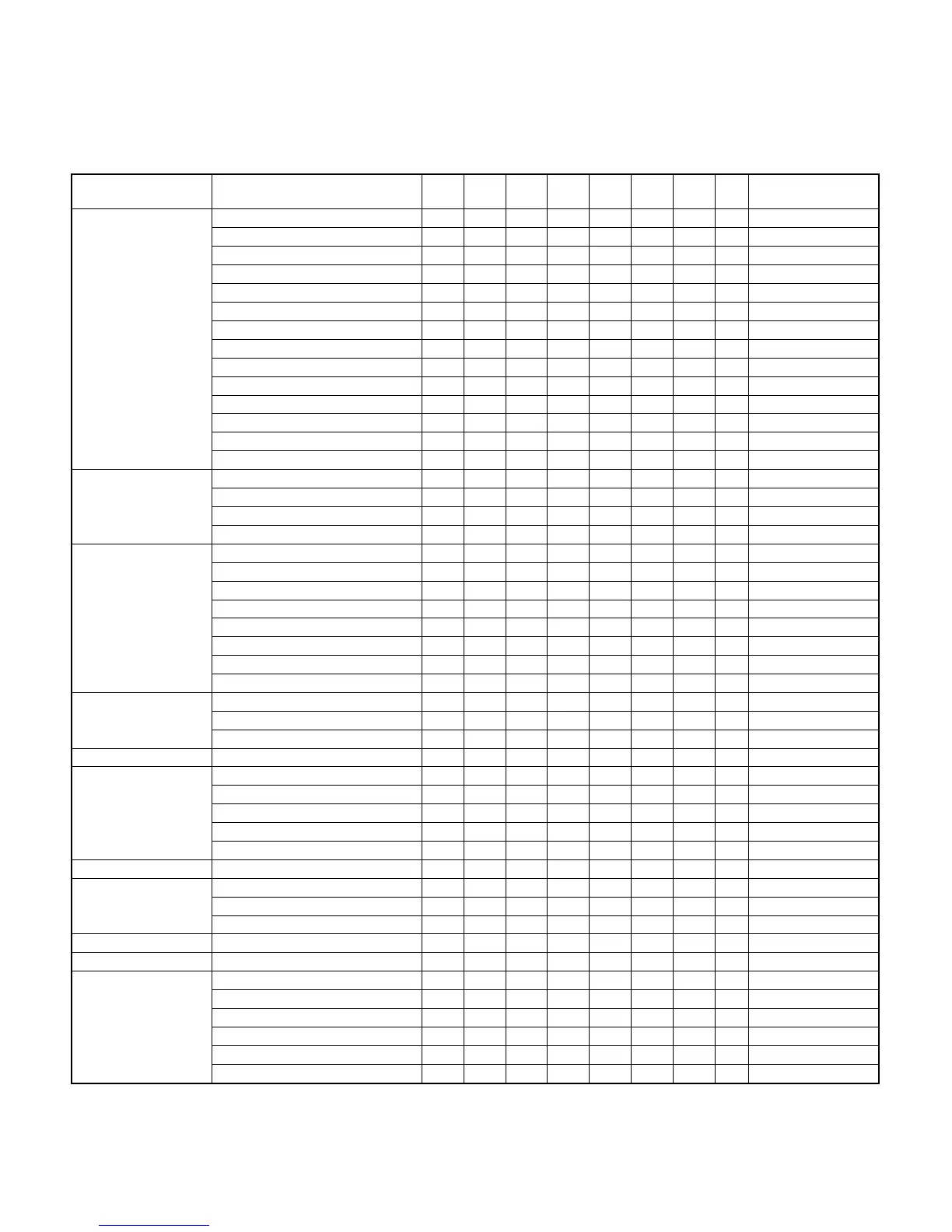

[9] MAINTENANCE AND OTHERS

The maintenance of the SF-2040 should be performed every 80K and 120K cycles.

<Remarks>

★= lubrication, F=cleaning, v=adjustment, b=replacement/mounting, k=repositioning,

✕=check (cleaning, replacement and/or adjustment if necessary)

* Toner consumption and waste toner bottle replacement cycle are replacement cycle when using the reference chart (6% original).

Unit name Part name 40K 80K 120K 160K 200K 240K 280K

320K

Note

Process UN Drum bbbb

Cleaner blade bbbb

Toner reception seal bbbb

Cleaner seal bbbb

Charging plate UN (saw teeth) bbbb

Screen grid bbbb

MC case FFFF

Drum separation pawl bbbb

B.L. FFFF

D.L. FFFF

Density sensor FFFF

Drum mark sensor FFFF

TC wire bbbb

TC case FFFF

Developing UN Developer bbbb

DV seal bbbb

DSD color FFFF

DV side seal bbbb

Fusing UN Upper heat roller bbbb

Lower heat roller bbbb

Upper/lower cleaning roller bbbb

Upper separation pawl bbbb

Lower separation pawl bbbb

Thermistor FFFF

Heat roller gear bbbb

Gears ★★★★

Optical UN Mirror lens / Reflector / Sensors FFFF

Table glass / Dust-proof glass FFFF

Rails ★★★★

Ozone filters / filters bbbb

Paper feed section * Paper feed roller ✕✕✕✕*2

D23 * Reverse roller ✕✕✕✕*2

* Take-up roller ✕✕✕✕*2

* Torque limiter ✕✕✕✕

Brake SP ★★★★

Suction Suction belt FFFF

Transport section PS roller FFFF

Transport rollers FFFF

Paper guides FFFF

Drive Gears ★★★★

Picture quality vvvv

ADU (DM11) * Paper feed roller ✕✕✕✕✕✕✕✕*3

* Reverse feed roller ✕✕✕✕✕✕✕✕*3

* Take-up roller ✕✕✕✕✕✕✕✕*3

* Torque limiter ★★★★

Transport rollers FFFF

Paper guides FFFF

*: Perform maintenance when the corresponding counter reaches the specified level.

*2: Replace every 80K or 2 years. (For the manual paper feed section, replace every 40K or 2 years.)

*3: Replace every 40K or 2 years.

9 – 1

Loading...

Loading...