5 Maintenance

5-6

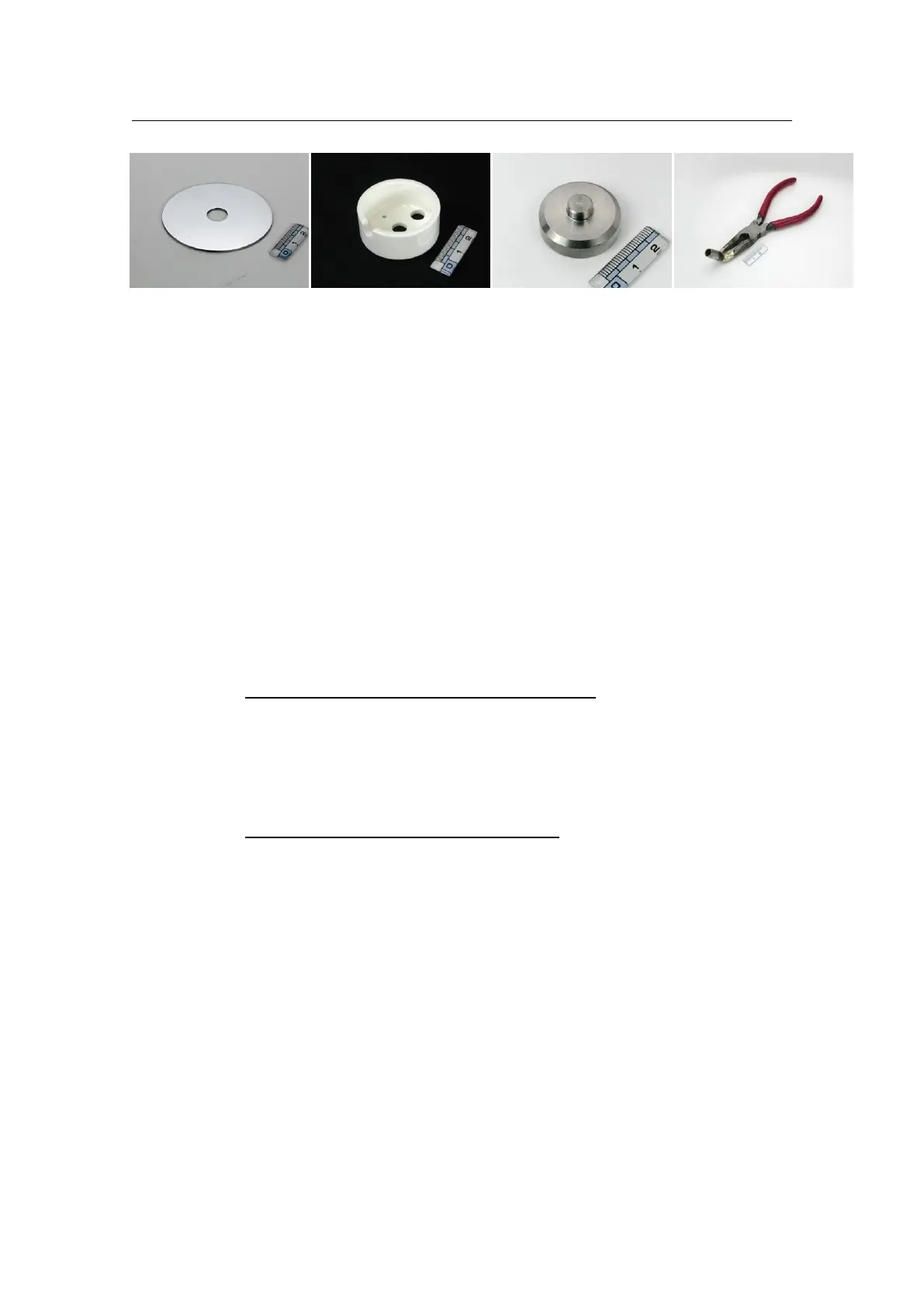

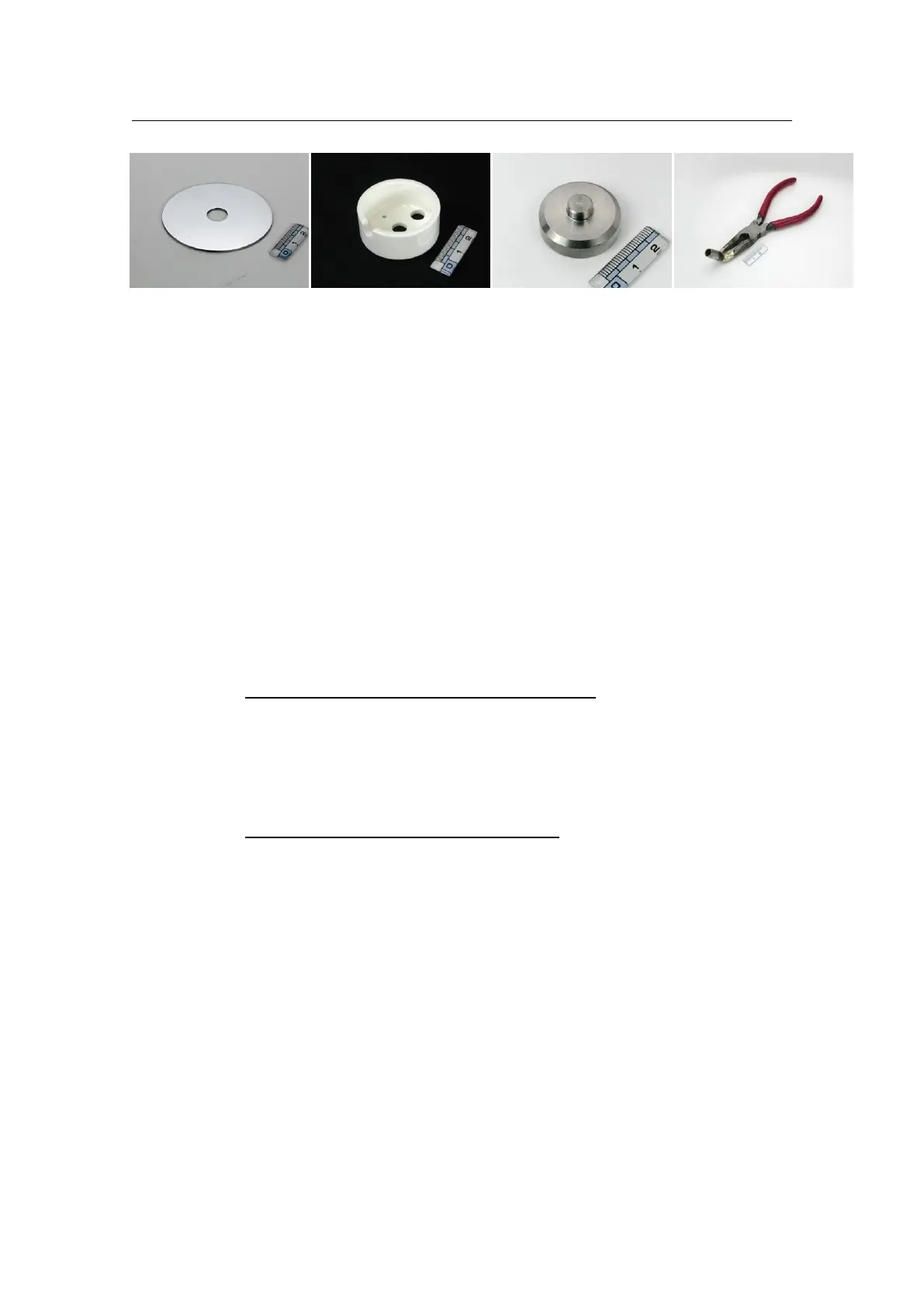

(From left to right)Sample plate, Dust cup, Gap gauge and Electrode removal tool

(1) Maintenance cycle

To remove evaporated sample from the tip of the electrode, either of the two

methods listed below is usually used. The maintenance cycle for the spark stand

depends on the method selected. (The cycle is described in the table about

periodical maintenance in page 5-2.)

<Cleaning by reverse discharge>

In this method, discharge is performed with the polarity of the sample and

electrode opposite to automatically remove evaporant.

If the reverse discharge time is too short, evaporant may not be removed

completely. On the contrary, if the reverse discharge time is too long, the tip

of the electrode may wear.

Maintenance cycle: Every 200 to 300 discharges

<Manual brushing>

In this method, the tip of the electrode is cleaned with the accessory brush

to remove evaporant. The tip of the electrode must be cleaned every time

analysis is finished to prevent excessive evaporant accumulation.

Maintenance cycle: Every 3,000 discharges

Performing either of the above shortens the electrode. The electrode can be used

until its total length becomes 65mm. (A new electrode is 100mm long.)

Loading...

Loading...