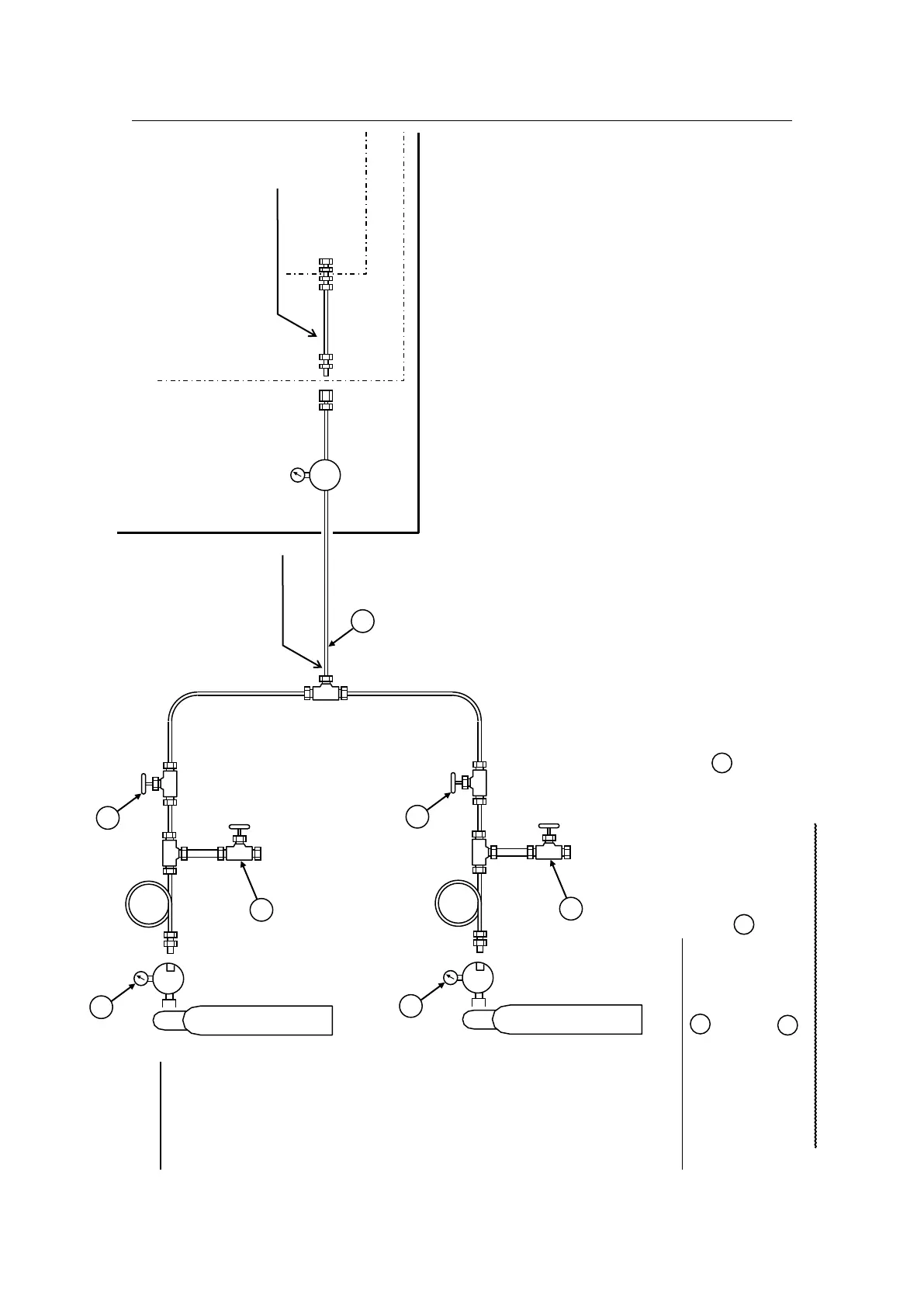

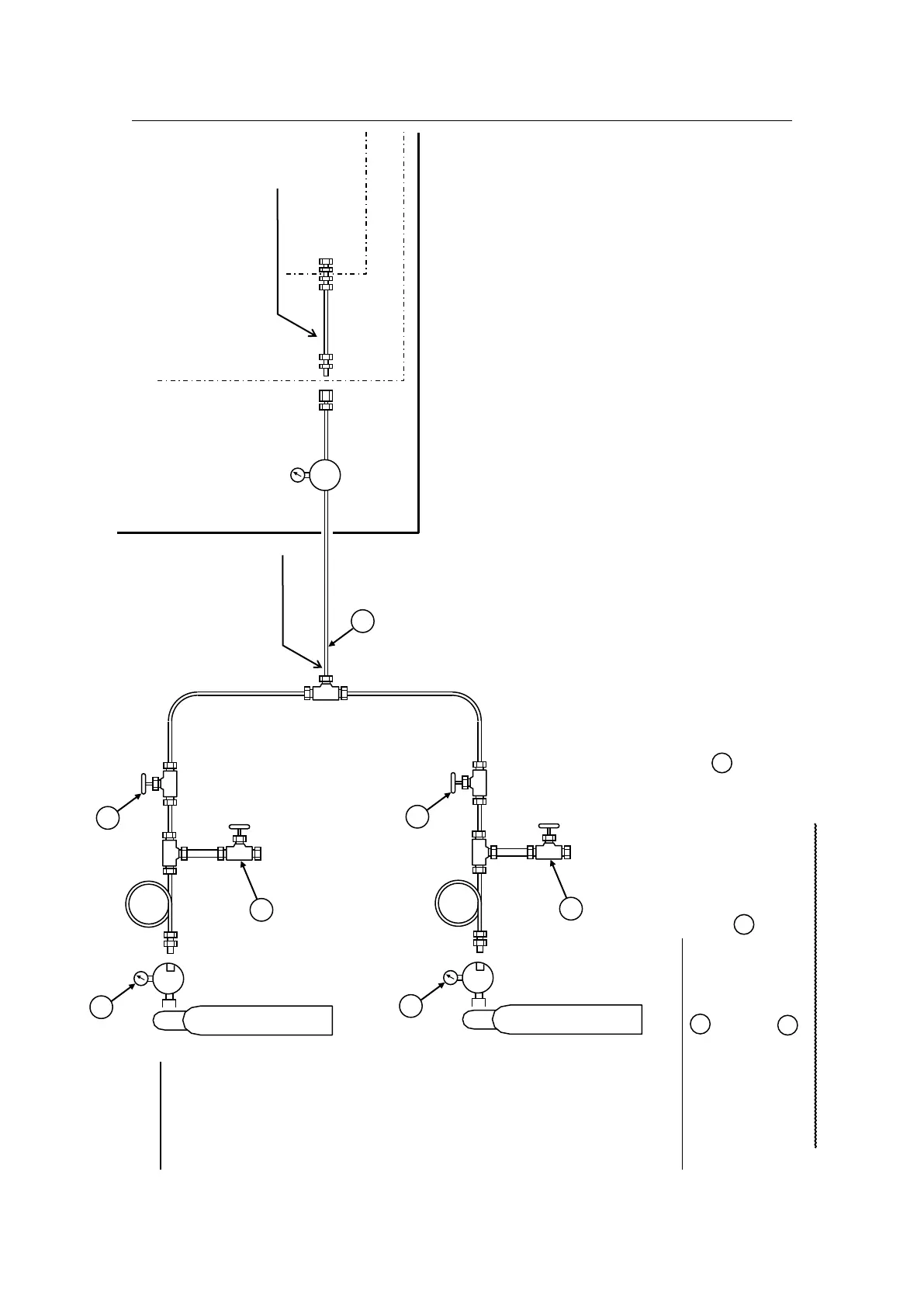

(1) Ar Regulator

Primary pressure

: 15MPa (150kgf / cm

2

)

Secondary pressure

: 140 - 200kPa (1.4

- 2.0kgf / cm

2

)

(ex.) P/N : 200

-33871

(2) Main valve

Use stainless steel type.

(3) Purge valve

Needed to

clear out the air after the change of gas cylinders.

(Place as close to main valve as possible)

(4) Plumbing pipe

(1) If the distance betwee

n gas cylinder and PDA

-7000 is

5m or less, use polypropylene tube. (P/N : 016

-43505)

(2) If the distance between gas cylinder and PDA

-7000 is

5 - 40m, set the secondary pressure to 500kPa (5kgf / cm

2

)

and place a regulator inside analysis room

to set t

he pressure at PDA

-7000 gas inlet 140

- 200kPa

(1.4 - 2.0kgf / cm

2

), as described with

♦ in the figure.

> Use stainless steel plumbing pipes for high purity

gases.

> For the details of the plumbing such as the thickness

of the pipe, consult a plumbe

r company.

Cylinder replacement procedure

(1) Close main valve 2 connected to the cylinder to be replaced.

(2) Repla

ce the Ar gas cylinder and open the valve of regulator 1 .

(3) Open and then close purge valve 3 several times, to clear out

the air and contamination.

(4) Open main valve 2 .

Take special care if nitrogen is to be measured.

Loading...

Loading...