4 MICROMASTER 430 functions

MICROMASTER 430 Operating Instructions

6SE6400-5AC00-0BP0

53

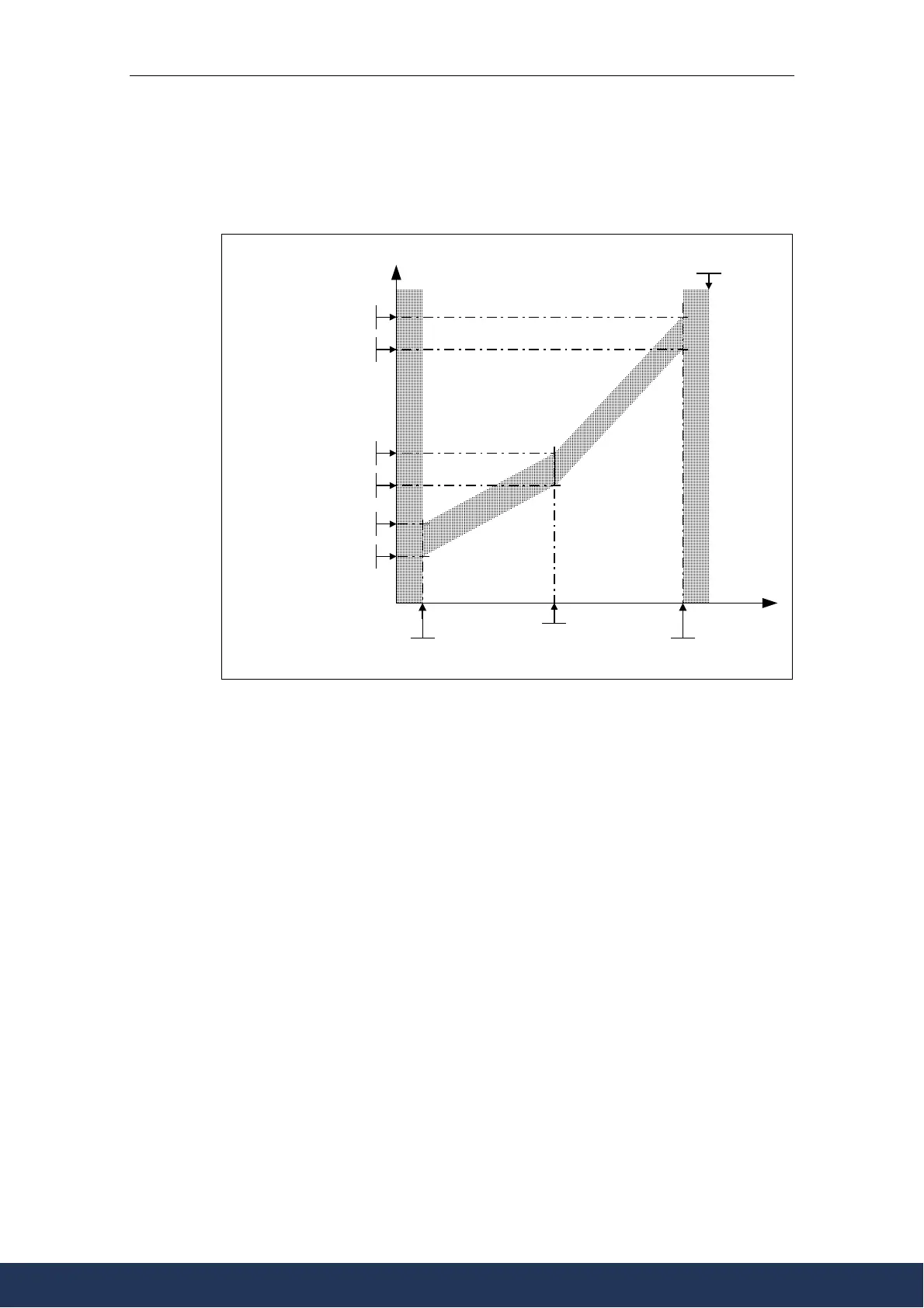

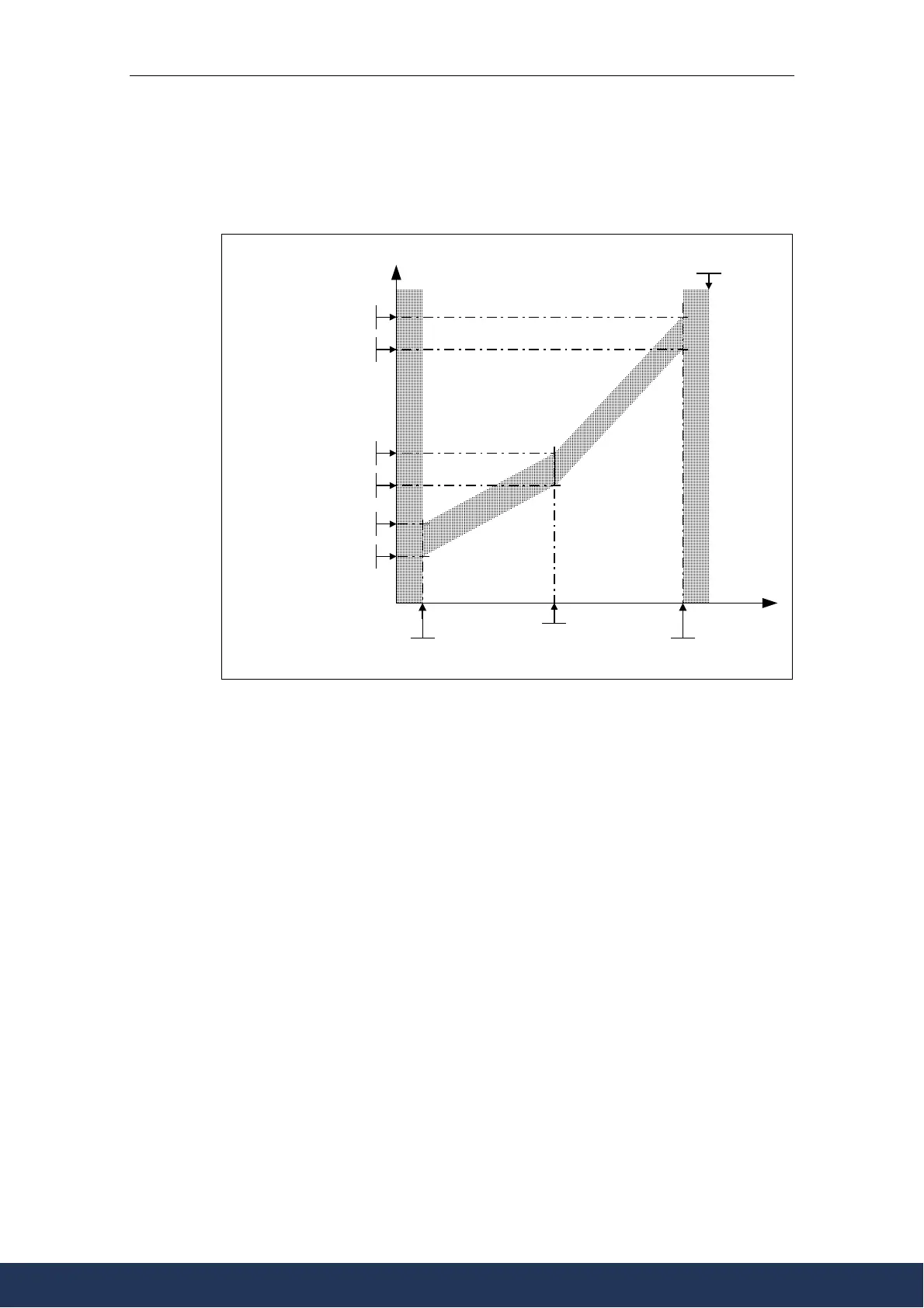

4.5.2 Belt Failure Detection

Recognizes mechanical faults in drive section e.g. torn V-belt, pumps which have

run dry etc.

P2189

Upper torque threshold 3

P2190

Lower torque threshold 3

P2187

Upper torque threshold 2

P2188

Lower torque threshold 2

P2185

Upper torque threshold 1

P2186

Lower torque threshold 1

P2182

Threshold frequency 1

P2183

Threshold frequency 2

P2184

Threshold frequency 3

Torque[Nm]

Frequency

[Hz]

P1082

Max. frequency

Figure 4-2 Belt Failure Detection

Function

A torque band is monitored. This enables underload and overload conditions to be

recognized (e.g. ventilator not running correctly)

Comparison between current speed / torque curve with programmed envelope

curve. The upper and lower frequency curve can be specified via three supporting

points each. In addition a dead time until the function is triggered can be defined.

This avoids accidental triggering due to transient events.

For additional settings please refer to parameter list P2181 and following.

www.eltra-trade.com

+421 552 601 099

info@eltra-trade.com

Loading...

Loading...