The Fundamentals of Motion Control

2-18

E Siemens AG, 2003 All rights reserved

SIMOTION C230-2, 04.2003 Edition

C230-2

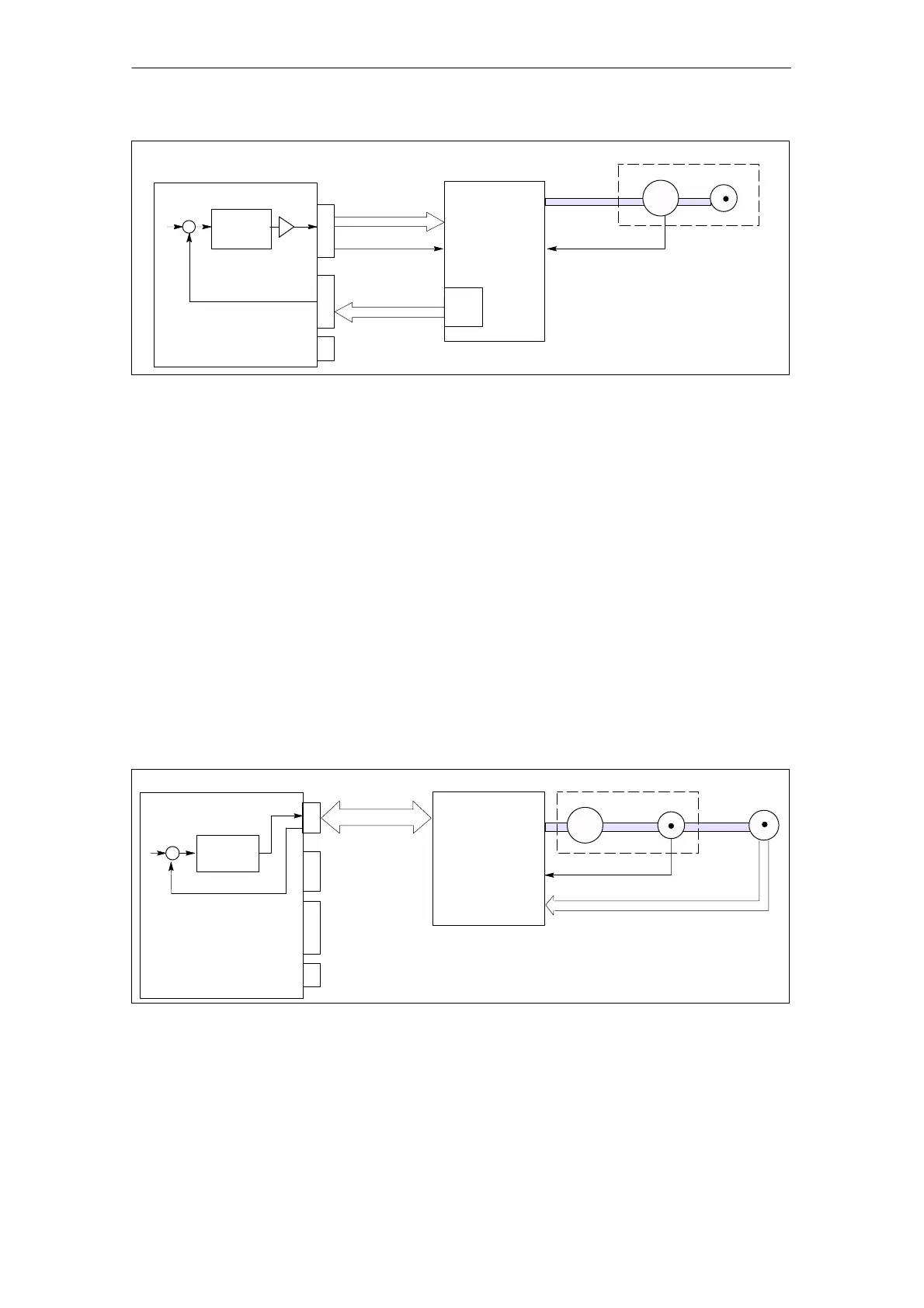

Position

controller

+

–

DAC

X2

X3

X4

X5

X6

X1

Speed setpoint

Power section

Current controller

Speed controller

M

3

Servo motor

Rotor position

Encoder

Converter

WSG

Enable

Actual position

value, zero mark

Fig. 2-2 Servo system with converter, e.g. SIMODRIVE 611 universal, with encoder emulation

Encoder emulation

Modern motor/converter systems often have a high-resolution motor measuring

system (rotor position encoder) connected at the converter. Here the converter

provides the position information via an interface that emulates an incremental en-

coder (e.g. incremental shaft encoder (WSG) interface with SIMODRIVE). A sepa-

rate position measuring system is not required in this case.

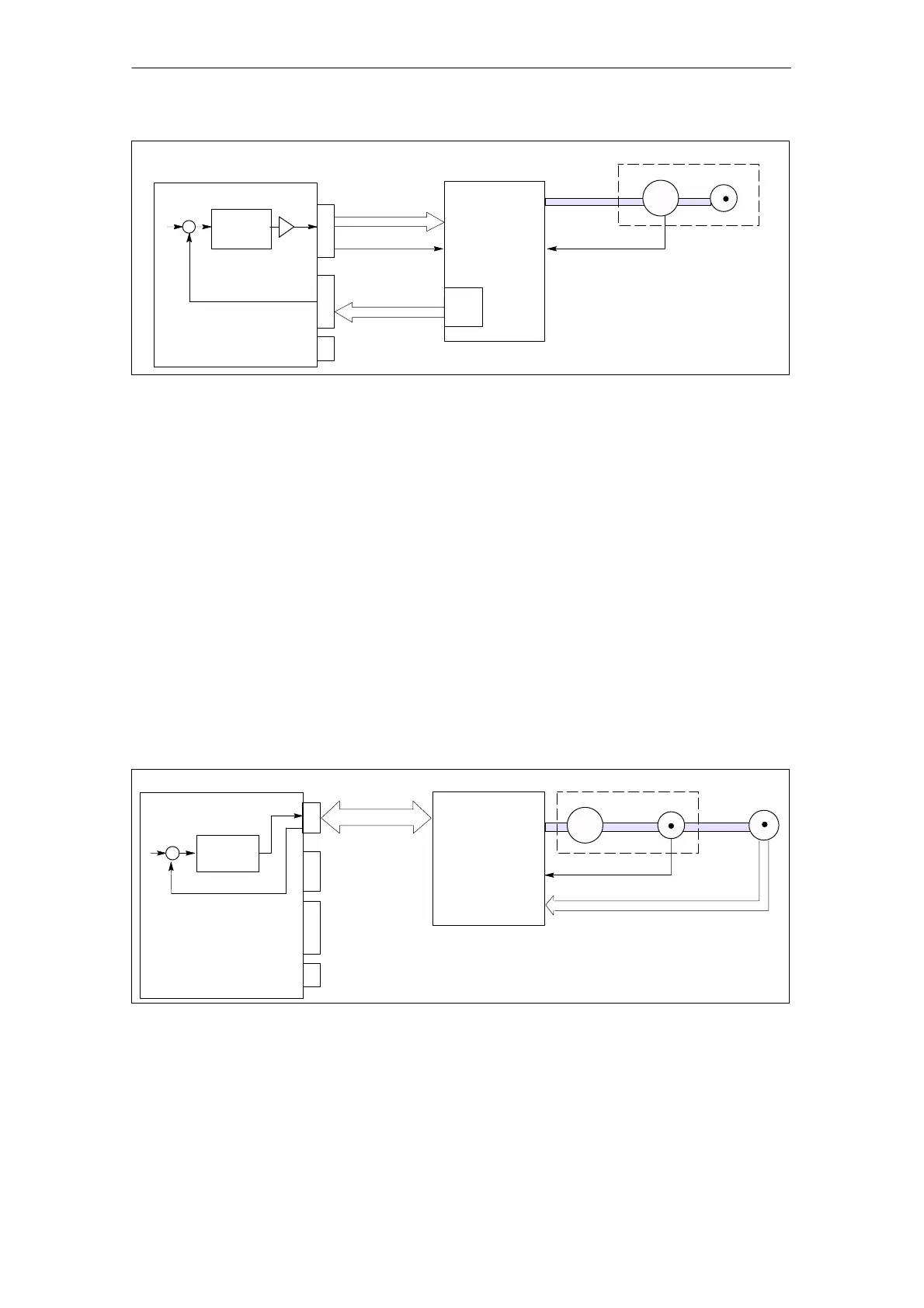

Position-controlled motion control for servo axes (PROFIBUS DP)

The C230-2 allows the position-controlled motion of axes via PROFIBUS DP.

The following PROFIBUS protocol is used for specifying the speed setpoint and

feeding back the actual position value:

PROFIdrive profile drive technology, Version 3 (isochronous)

C230-2

Position

controller

X2

X3

X4

X5

X6

X1

Speed setpoint

Power section

Current controller

Speed controller

M

3

Servo motor

Actual speed value

Encoder

Actual position value, zero mark

Converter

X9

Actual position value

PROFIBUS DP

+

–

Fig. 2-3 Servo system with converter, e.g. SIMODRIVE 611 universal

Loading...

Loading...